Controlled release fertilizer

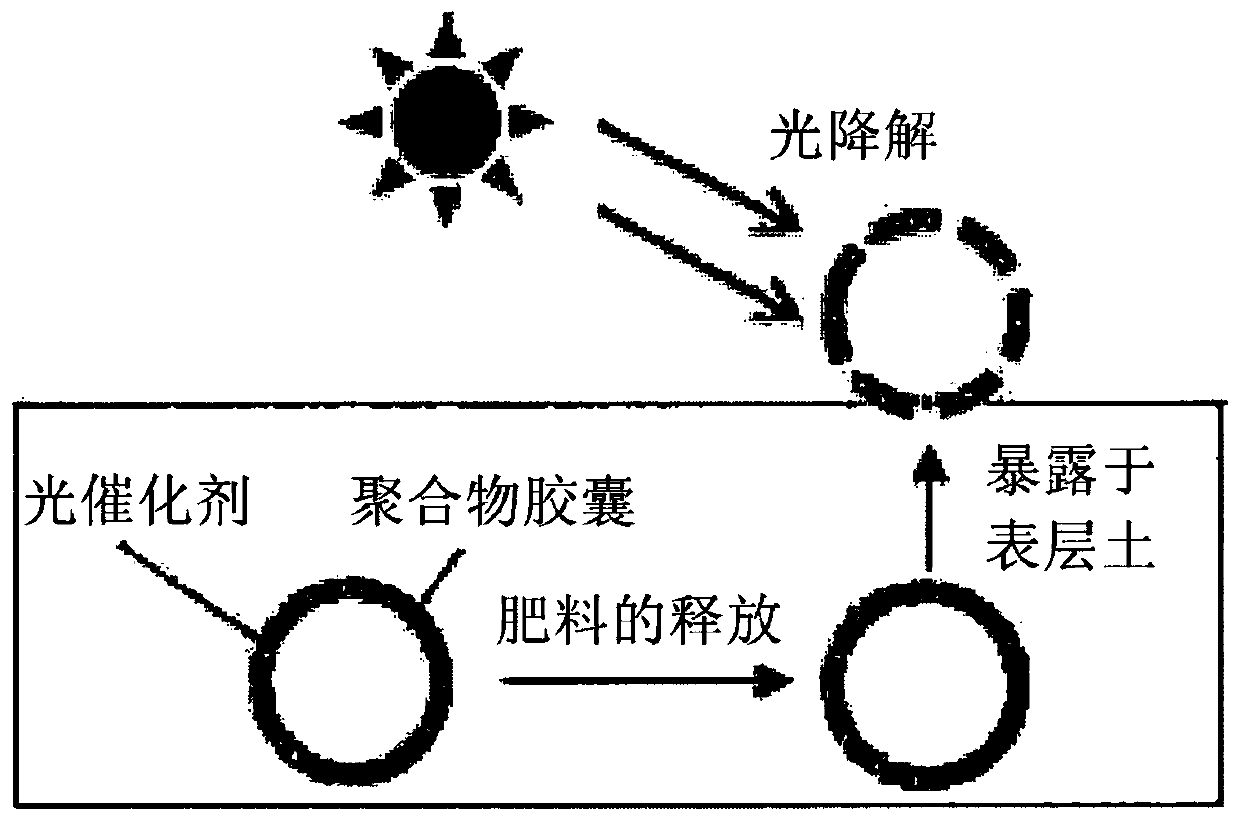

A technology for controlled-release fertilizers and fertilizers, applied in fertilizer mixtures, layered/coated fertilizers, solid/semi-solid fertilizers, etc., can solve problems such as being unsuitable for controlled-release fertilizers, and achieve overgrowth prevention, high compatibility, and uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

[0061] (1) Preparation of photocatalytic composite materials

[0062] 1.5 g of ethylene vinyl acetate copolymer [MI (melt index, 190 ° C, load 2.16 kg, ASTMD1238): about 1.8 g / 10 minutes, D (density): 0.94 g / cm 3 , the vinyl acetate content is about 20% by weight, and the melting point is 85° C.] dissolved in tetrachloroethylene, and TiO is mixed therein in the amount shown in Table 1 below 2 (average particle diameter of primary particles: 21 nm), and sonication was performed to prepare a dispersion solution of a photocatalytic composite material coated with ethylene vinyl acetate copolymer.

[0063] (2) Preparation of controlled release fertilizer

[0064] The amount shown in Table 1 below uses the dispersion solution of the photocatalytic composite material thus prepared, polyethylene [LDPE, MI (melt index, 190° C., load 2.16 kg, ASTM D1238): about 8 g / 10 minutes, D (Density): 0.925g / cm 3 ], ethylene vinyl acetate copolymer [MI (melt index, 190°C, load 2.16kg, ASTM D1238...

experiment example 1

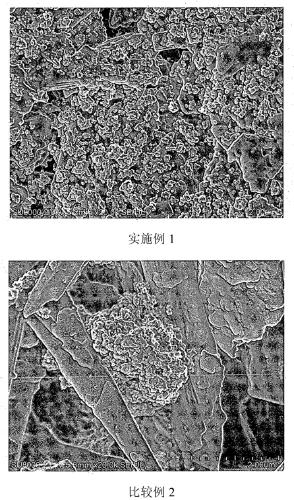

[0074] Experimental example 1: Comparative test of photodegradation characteristics

[0075] Take each 5g of the controlled-release fertilizer of the embodiment and the coated fertilizer of the comparative example, and use a needle to make pinholes one by one to release the fertilizer completely. Then, the degradation evaluation was performed on the remaining coating film.

[0076] Using Suntest CPS+ equipment (ATLAS) at a temperature of 50 ℃ to light with a wavelength of 300nm to 800nm at 400w / m 2 The intensity of the radiation hits the coating film.

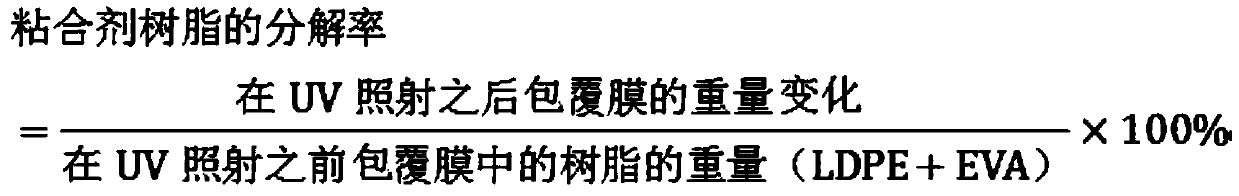

[0077] Then, the decomposition rate of the binder resin, which can be obtained from the weight change of the coating film during 224 hours of light irradiation under the above-mentioned conditions, was determined by the following general formula 1, and the results are shown in Table 1 below.

[0078] [Formula 1]

[0079]

[0080] [Table 1]

[0081]

[0082] As shown in Table 1, it is determined that when light with ...

experiment example 2

[0083] Experimental Example 2: Evaluation of Release Characteristics of Fertilizers

[0084] 12.5 g each of the controlled-release fertilizer of the example and the coated fertilizer of the comparative example were added to 250 ml of distilled water to prepare a sample. Then, 1 ml of liquid was withdrawn from the samples at 25° C. on different days and analyzed (Kjeltec Analyzer 2300) for nitrogen content in the samples to measure the amount of released fertilizer.

[0085] [Table 2]

[0086]

[0087] As shown in Table 2, it was confirmed that the controlled-release fertilizer of Example 1 exhibited a release rate of 50% or more after 20 days and a release rate of 90% or more after 50 days. In contrast, it was also confirmed that the coated fertilizer of Comparative Example 1 exhibited a release rate of less than 40% after 20 days and even less than 70% or less on the 50th day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com