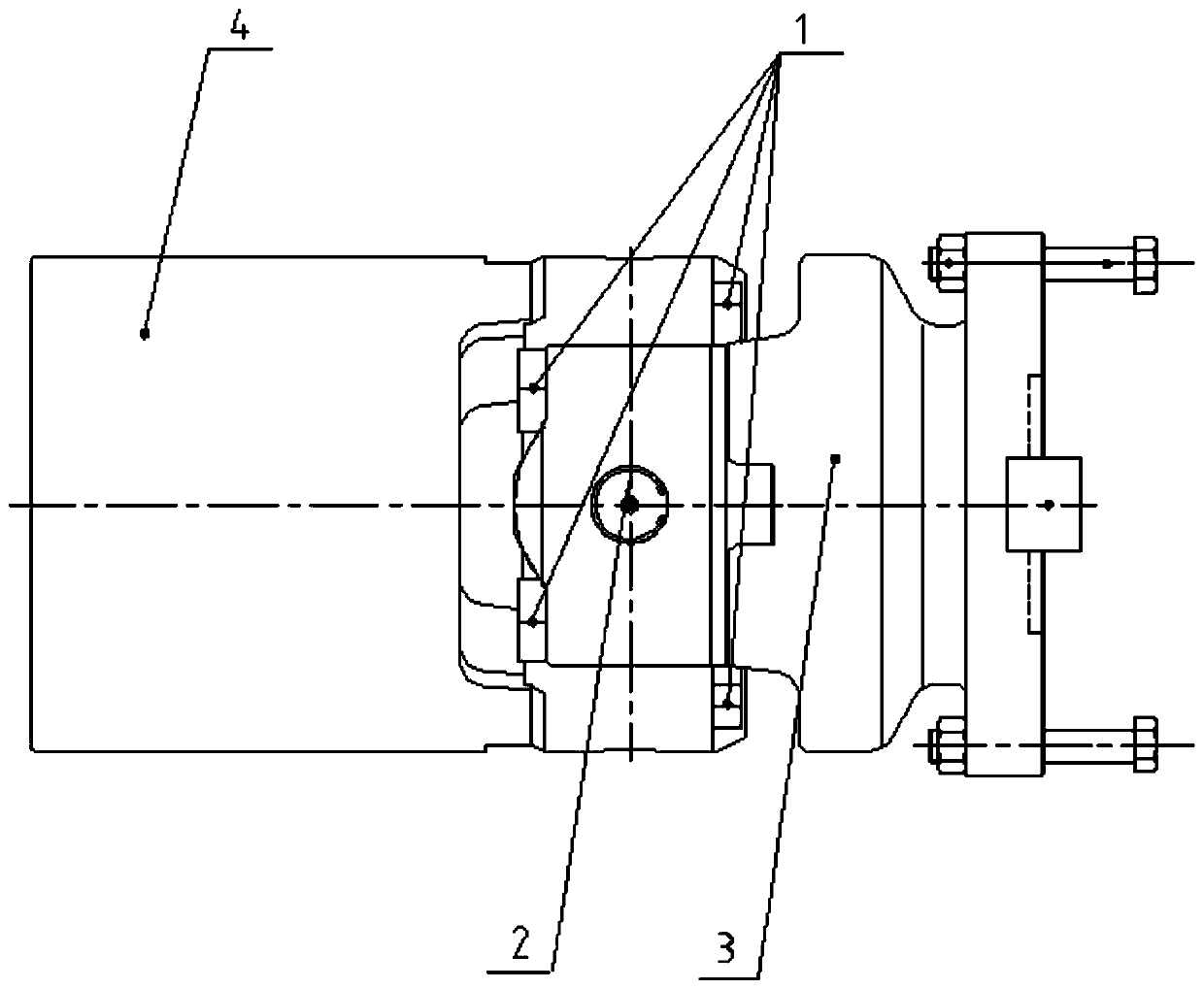

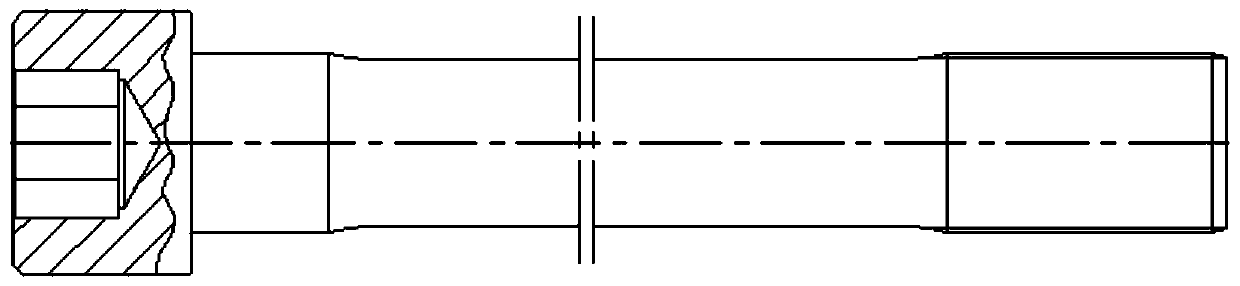

High-performance bolt of bearing seat type joint and manufacturing method thereof

A manufacturing method and high-performance technology, applied to bolts, manufacturing tools, nuts, etc., can solve problems such as low surface hardness, poor surface roughness, and poor wear resistance, and achieve improved mechanical properties, increased strength, and good Corrosion-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

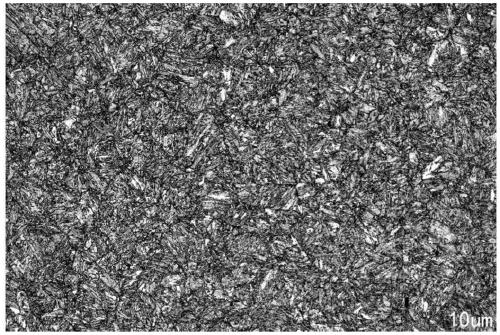

[0033] The mass percentage of the high-performance bolt of the bearing seat type joint of the present invention is preferably: C: 0.22%, Mn: 0.51%, Si: 0.056%, P: 0.0005%, S: 0.0019%, Ni: 3.80%, Cr: 1.88%, Mo: 0.35%, V: 0.08%, Nb: 0.08%, and the balance is Fe.

Embodiment 2

[0035]The mass percent of the high-performance bolt of the bearing seat type joint of the present invention is preferably: C: 0.25%, Mn: 0.66%, Si: 0.046%, P: 0.0008%, S: 0.0012%, Ni: 3.58%, Cr: 2.14%, Mo: 0.40%, V: 0.09%, Nb: 0.06%, and the balance is Fe.

Embodiment 3

[0037] The mass percent of the high-performance bolt of the bearing seat type joint of the present invention is preferably: C: 0.28%, Mn: 0.62%, Si: 0.06%, P: 0.001%, S: 0.001%, Ni: 3.72%, Cr: 1.96%, Mo: 0.44%, V: 0.07%, Nb: 0.10%, and the balance is Fe.

[0038] Table 1 shows the chemical composition mass percentages of the imported material SNCM630 in the three embodiments of the present invention and the background technology.

[0039] Table 1. Material composition of high-performance bolts of bearing housing type joints (wt,%)

[0040] category C mn Si P S Cr Mo Ni V Nb Example 1 0.22 0.51 0.056 0.0005 0.0019 1.88 0.35 3.80 0.08 0.08 Example 2 0.25 0.66 0.046 0.0008 0.0012 2.14 0.40 3.58 0.09 0.06 Example 3 0.28 0.62 0.06 0.001 0.001 1.96 0.44 3.72 0.07 0.10 comparative example 0.33 0.44 0.24 0.023 0.012 2.76 0.68 2.57 / /

[0041] As can be seen from the above table, the high-perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com