Ecological and environment-friendly wallboard of integrated house and preparation process thereof

An integrated house, environmental protection technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems that the quality of the integrated house needs to be improved, the surface of the integrated house is easy to absorb moisture, and small cracks are easy to appear, and achieve excellent overall stability , excellent waterproof and sound insulation performance, and unique fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

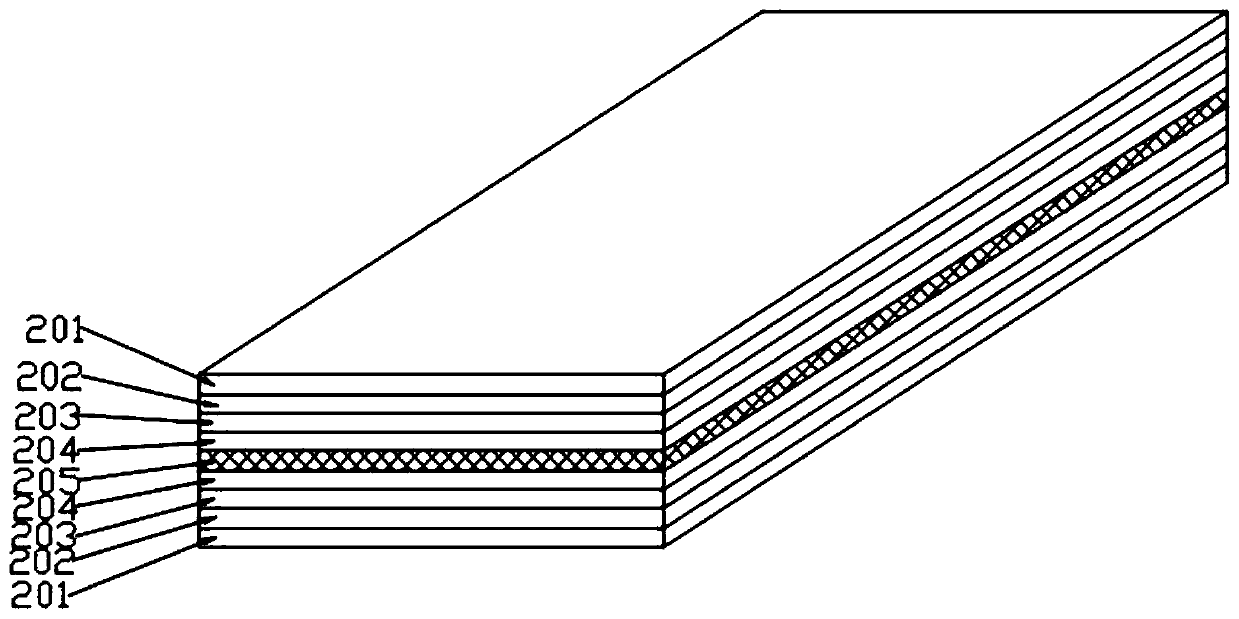

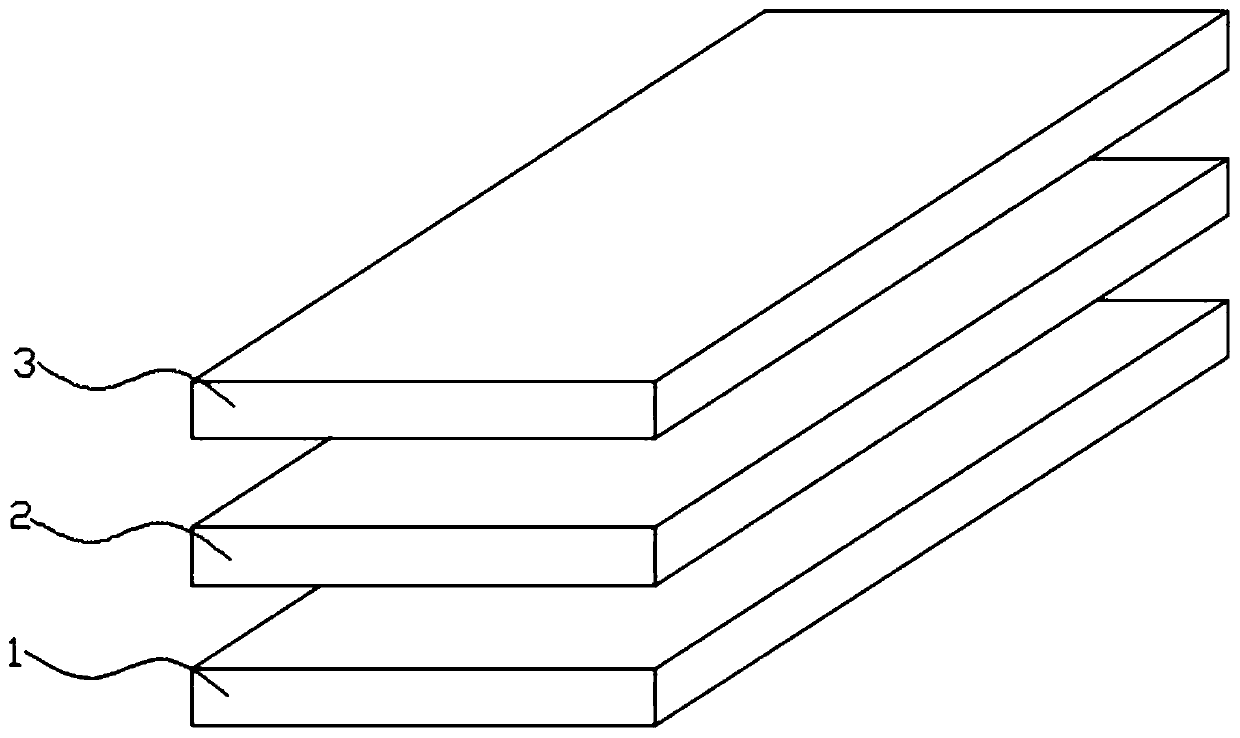

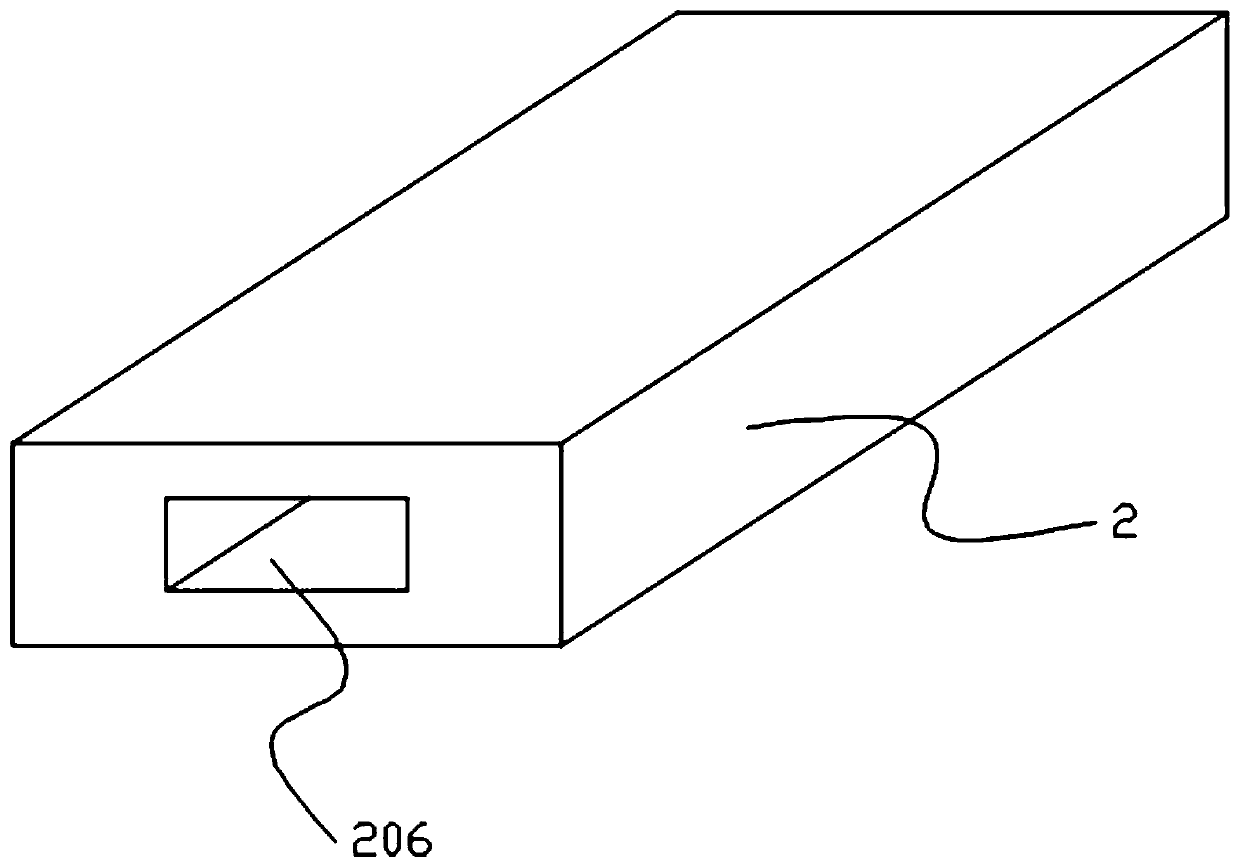

[0061] like figure 1 and figure 2 As shown, an eco-environment-friendly integrated house wall panel includes a bottom board 1, a reinforcement board 2 and a top board 3 bonded in sequence, and the bottom board 1, reinforcement board 2 and top board 3 all include 9 layers of boards Composite boards, the 9 layers of said boards in the middle are steel filled boards 205, and the two sides of said steel filled boards 205 are respectively bonded with plant fiber filled boards 204 and carbon fiber boards 203 , the glass fiber waterproof board layer 202 and the magnesium oxide gel board layer 201.

[0062] The wallboard of the present invention adopts a three-layer composite structure, and each layer structure is formed by pressing and bonding 9 layers of boards, and the outermost two layers are made of magnesium oxide gel board layer 201 as the basic surface, which is convenient for bonding with other board layers. The inner layer is provided with a glass fiber waterproof board l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com