Method for detecting lithium-embedded pole piece of lithium ion secondary battery

A technology for secondary batteries and detection methods, which is applied to measurement devices, material inspection products, and preparation of test samples, etc., can solve the problems of fire and burning equipment, damage, affecting the analysis and judgment of pole piece testing, and achieves simple, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

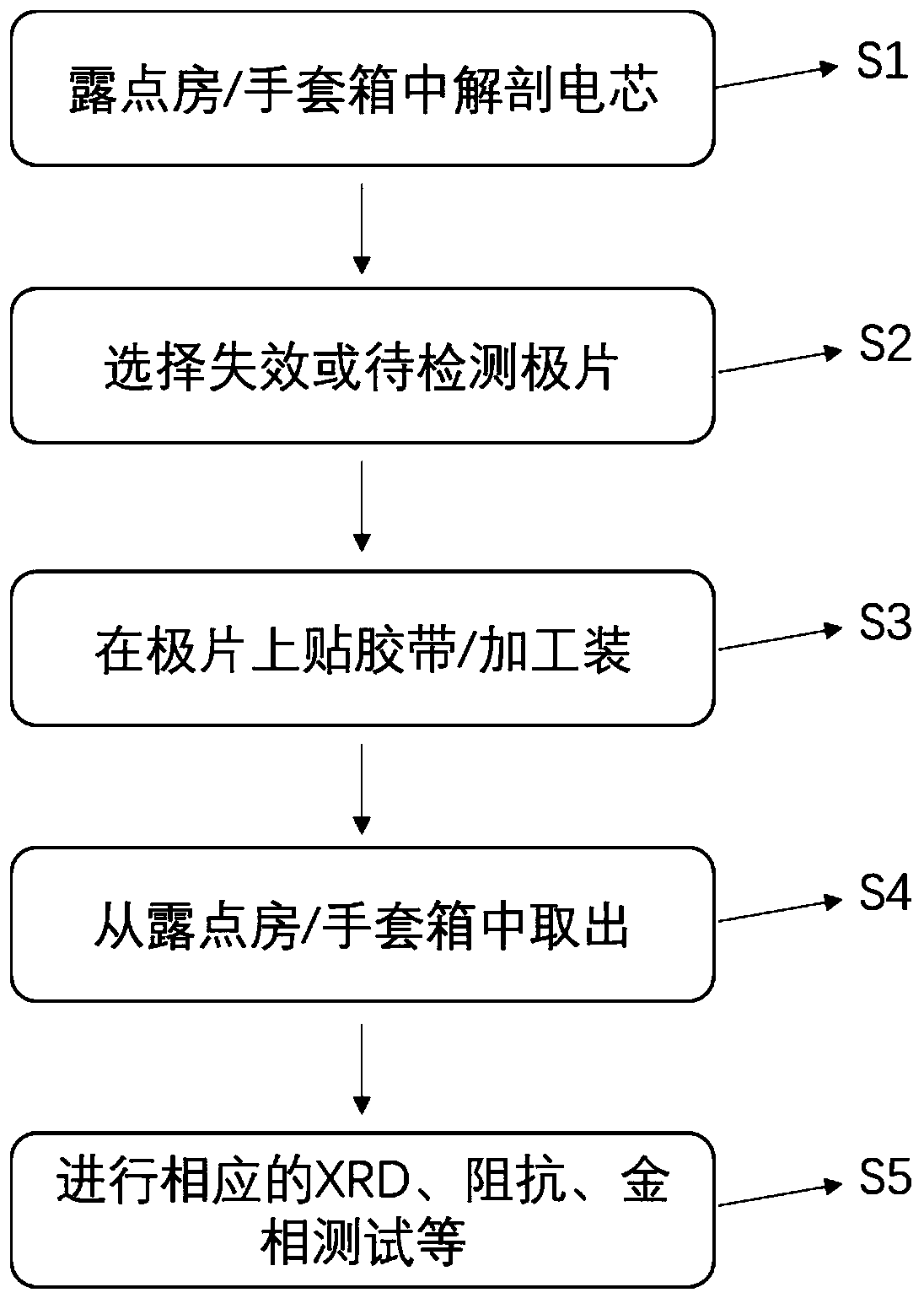

Method used

Image

Examples

Embodiment 1

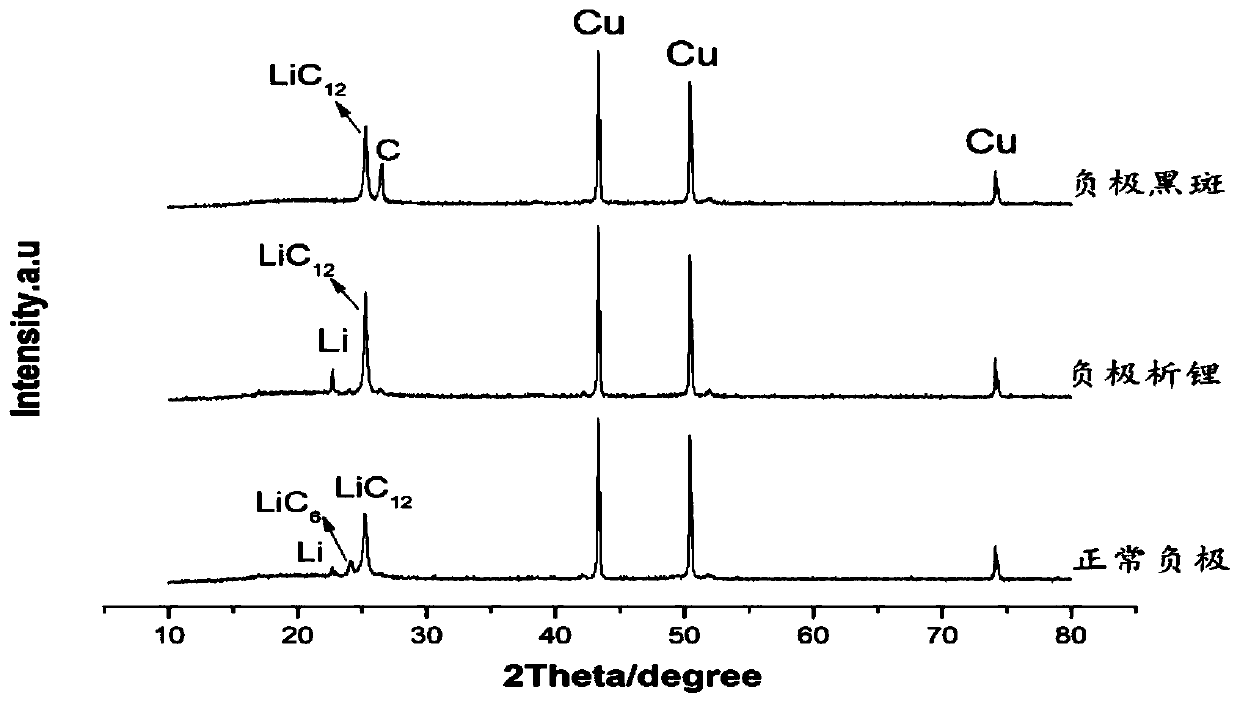

[0038] like figure 1 As shown, the negative electrode sheet in the normal lithium intercalation area was pasted with Kapton-polyimide tape. In the dew point room, an iron-lithium 80Ah square aluminum shell battery cell that failed in the standard cycle was dissected. The core failed; it was taken out after dissection, and there were "lithium analysis" and "black spots" among them. After taking it out of the dew point room, carry out XRD test on the negative plate of the failed cell, the test result is as follows: figure 2 shown; where only LiC exists in the "dark spot" area 12 and graphite phase diffraction peaks, only Li and LiC exist in the "lithium analysis" region 12 Phase diffraction peaks, there are Li, LiC in the normal lithium intercalation region 12 and LiC 6 phase, but LiC 12 The relative peak intensity of the phase is significantly higher than that of LiC 6 Mutually;. LiC was not detected in both the "black spot" and "lithium analysis" regions 6 phase, ind...

Embodiment 2

[0040] The normal 10Ah iron-lithium soft-packed cells with the state of charge kept at 40%, 60%, 80% and 100% (full charge state) SOC were dissected in the glove box, and the water and oxygen content in the glove box were all ≤ 1ppm ;Respectively take a piece of negative electrode sheet of the battery cell whose state of charge is maintained at 40%, 60%, 80% and 100%, and paste Kapton-polyimide high-temperature tape; take the negative electrode sheet with the tape attached XRD test. Test results such as image 3 shown.

[0041] It can be concluded that the negative electrode Li in different states of charge x C 6 (06 and LiC 12 The relative peak intensity of the phase can indirectly judge the intercalation of lithium ions in the graphite layer gap and the rationality of the N / P ratio in the design of the cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com