Tungsten electrode and its preparation method, and high-pressure discharge lamp using the tungsten electrode

A high-pressure discharge lamp, tungsten electrode technology, applied in the field of optoelectronics, can solve the problems of ineffectiveness, high price and short life, etc., and achieve the effects of convenient processing technology, low processing cost, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the embodiment of the preparation method of the tungsten electrode of the present invention:

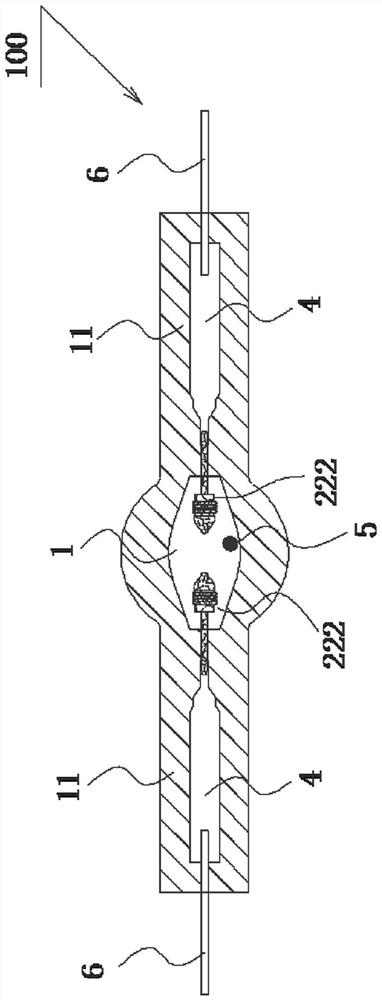

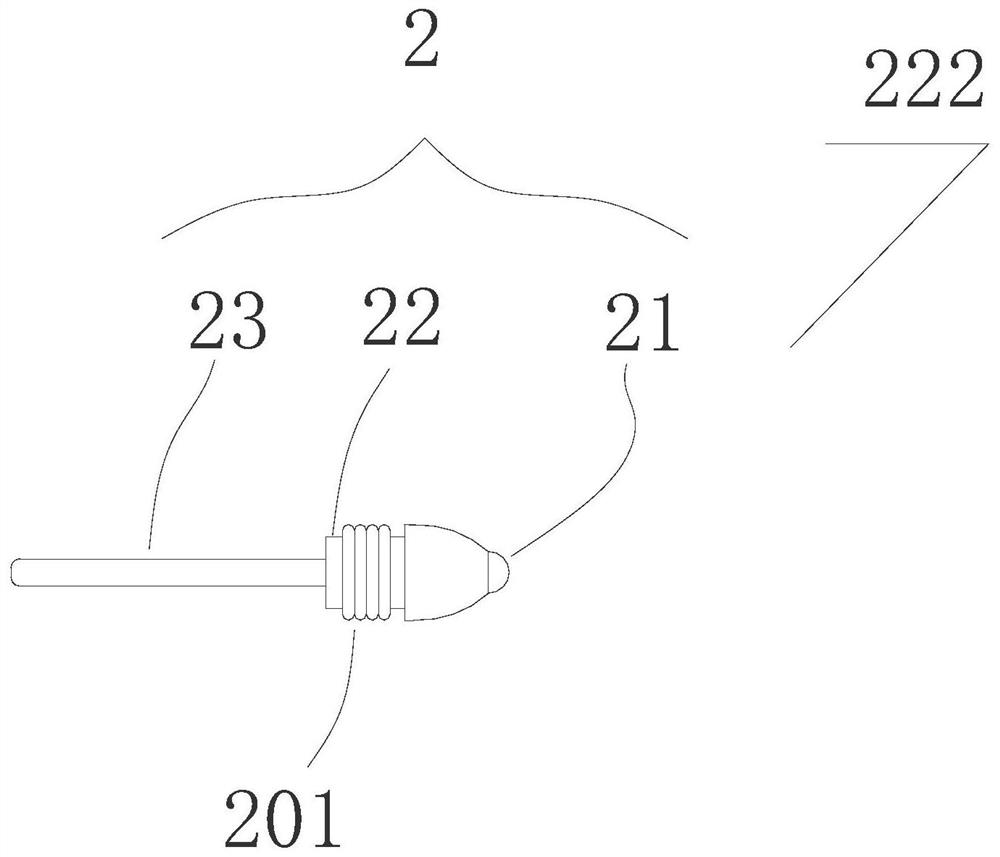

[0039] S1) Select a tungsten bar with a diameter of 0.9 to 3.0mm or a tungsten alloy bar with tungsten as the main component, such as a bar with a diameter of 1.6mm, which is turned into a tungsten electrode body 2 and assembled with a tungsten coil 201. The tungsten coil 201 can be fixed on the tungsten electrode body 2 after turning by mechanical pressing or welding, and the tungsten electrode 222 having the discharge part 21, the ionization trigger part 22 and the support part 23 can be made as follows: figure 2 ; The number of turns of the tungsten coil 201 can be selected from 4 to 10 turns, such as 4 turns, and a gap is formed between two adjacent coils and electrodes to form a potential at the gap when the high-pressure discharge lamp is loaded and started at an ultra-high voltage (above 2KV). Poor, ionization is formed, which further induces arcing between the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com