Post-processing technology of 3D highlight mobile phone rear cover

A technology for mobile phone back cover and processing technology, which is applied in the direction of telephone structure, anodizing, telephone communication, etc., can solve the problems of inability to achieve consistency in the color of the back cover, highlighting effect, single color, and weak installation of fittings, etc. Achieve the effect of eliminating the defect rate, ensuring the highlight effect, and the removal method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

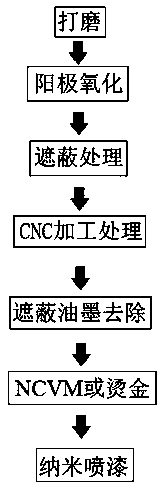

[0023] Examples, see attached figure 1 , a post-processing process for a 3D bright mobile phone back cover, comprising the steps of:

[0024] S1. Grinding: Use a polishing machine to grind and polish the outer surface of the back cover of the mobile phone to obtain a polished piece; specifically, use a pneumatic or electric grinder to perform pre-shading treatment on the surface of the back cover of the mobile phone, and the pre-shading treatment is 5- 6 times, the polishing time is 1 minute, and the surface gloss of the back cover of the mobile phone after polishing is 600±100GU.

[0025] S2. Anodizing: Anodize the outer surface of the polished piece; use anodic oxidation to put the polished piece into the electrolyte for electrolysis, the electrolysis time is 500-800 seconds, the anode film thickness is 5-7 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com