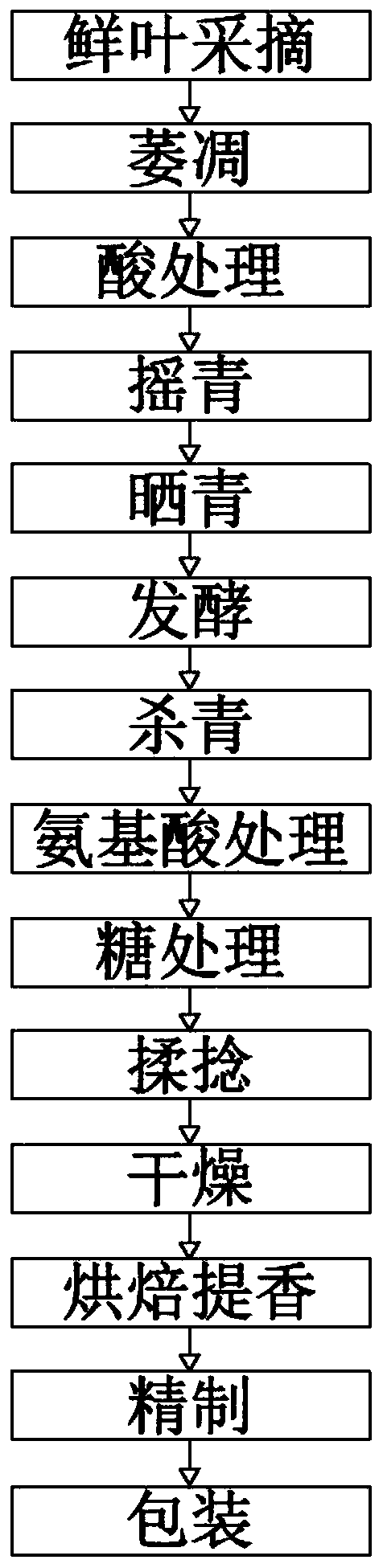

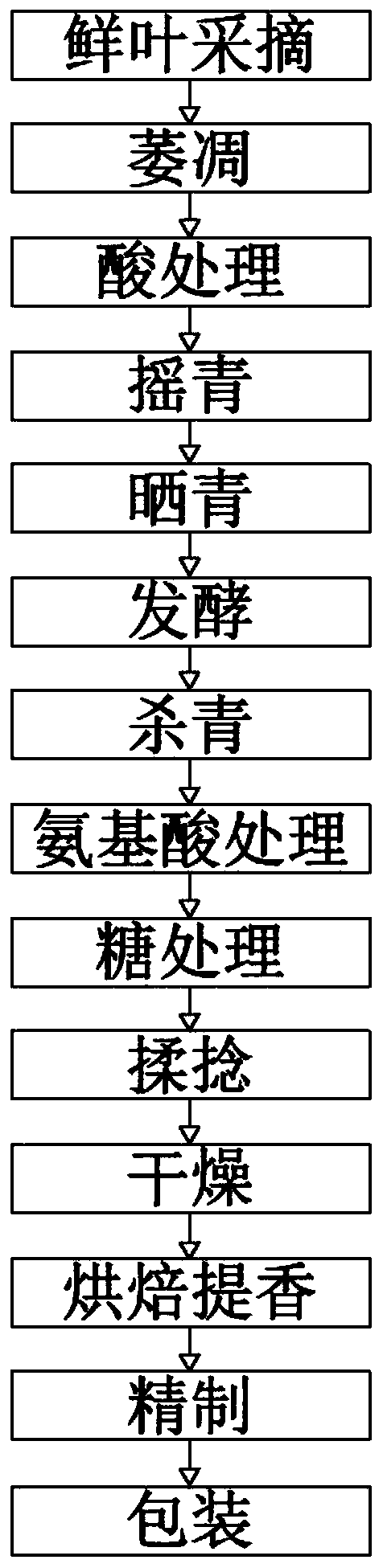

Processing technology of oolong tea

A processing technology, oolong tea technology, applied in the field of oolong tea processing technology, can solve the problems of insufficient aroma of tea leaves, low amount of nutrients soaked in tea soup, etc., and achieve the effect of improving flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] S1 fresh leaf picking: Hand-picked fresh leaves of tea trees with one bud and two leaves or one bud and three leaves without pests and diseases;

[0038] S2 Withering: spread the fresh tea leaves to a thickness of 2 cm, wither for 2 hours under soft sunlight, and then transfer to a well-ventilated room with a temperature of 22 ° C and an air humidity of 60% to wither for 10 hours. During the entire withering process, every Stir once every 1 hour to obtain withered leaves;

[0039] S3 acid treatment: Spray a citric acid solution with a concentration of 0.3mol / L into the withered leaves according to the amount of 3ml per kilogram of withered leaves and mix well, then store in a breathable fresh-keeping bag for 2 hours to obtain acid-treated leaves;

[0040] S4 shaking green: put the acid-treated leaves into the green shaking machine, shake the green leaves for 3 minutes at a speed of 6 rpm, a temperature of 22°C, and a humidity of 40%, and then stop for 10 minutes; Shake...

Embodiment 2

[0052]S1 fresh leaf picking: Hand-picked fresh leaves of tea trees with one bud and two leaves or one bud and three leaves without pests and diseases;

[0053] S2 Withering: spread the fresh tea leaves to a thickness of 3 cm, wither under soft sunlight for 3 hours, and then transfer to a well-ventilated room with a temperature of 23 ° C and an air humidity of 65% to wither for 11 hours. During the entire withering process, every Stir once every 1.5 hours to obtain withered leaves;

[0054] S3 acid treatment: Spray a citric acid solution with a concentration of 0.5 mol / L into the withered leaves according to the amount of 4ml per kilogram of withered leaves and mix well, then store in a breathable fresh-keeping bag for 3 hours to obtain acid-treated leaves;

[0055] S4 shaking green: put the acid-treated leaves into the green shaking machine, shake the green leaves for 4 minutes at a speed of 8 rpm, a temperature of 23°C, and a humidity of 45%, and then stop for 13 minutes; Sh...

Embodiment 3

[0067] S1 fresh leaf picking: Hand-picked fresh leaves of tea trees with one bud and two leaves or one bud and three leaves without pests and diseases;

[0068] S2 Withering: spread the fresh tea leaves to a thickness of 4 cm, wither for 4 hours under soft sunlight, and then transfer to a well-ventilated room with a temperature of 24 ° C and an air humidity of 70% to wither for 12 hours. Stir once every 2 hours to obtain withered leaves;

[0069] S3 acid treatment: Spray a citric acid solution with a concentration of 0.6mol / L into the withered leaves according to the amount of 5ml per kilogram of withered leaves and mix well, then store in a breathable fresh-keeping bag for 4 hours to obtain acid-treated leaves;

[0070] S4 shaking green: put the acid-treated leaves into the green shaking machine, shake green at 10 rpm, temperature 24°C, humidity 50% for 5 minutes, then stop for 15 minutes; reverse rotation speed 30rpm, temperature 25°C, humidity 60% Shake the green leaves fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com