Preparation method of physical sun-screening agent for cosmetics

A technology for physical sunscreens and cosmetics, applied in the direction of cosmetic preparations, cosmetics, skin care preparations, etc., can solve problems that do not involve the catalytic activity of nano-cerium oxide oxidation, discoloration and odor of nano-cerium oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

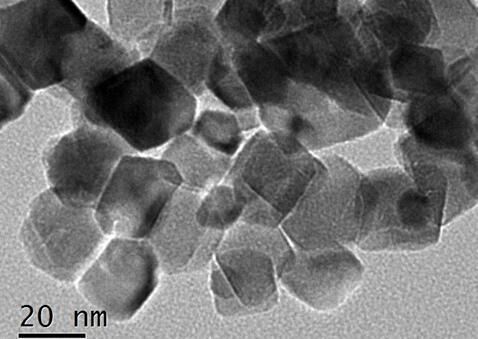

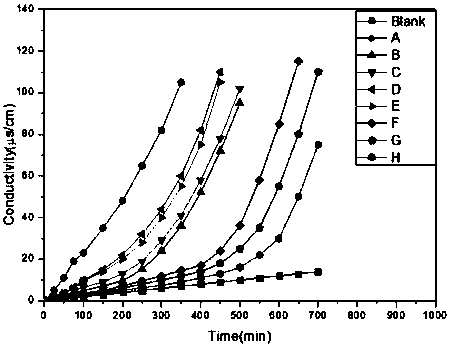

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific examples.

[0030] 1. Embodiment: a kind of preparation method of physical sunscreen for cosmetics.

[0031]

[0032] Preparation Process:

[0033] (1) Weigh the cerium source, add 2L deionized water and stir to dissolve completely, then add non-ionic surfactant and stir evenly, heat to 35°C;

[0034] (2) At a stirring speed of 400rpm, slowly add KOH solution dropwise to adjust the pH to 7, heat to 150°C and stir for 18 hours, then cool down with stirring;

[0035] (3) Lower the temperature to 40°C and add sufficient hydrogen peroxide solution to stir for 5 hours to react completely to form Precipitate A, and then separate Precipitate A;

[0036] (4) Add deionized water to prepare the precipitate A into a slurry, add an inorganic coating agent, add hydrochloric acid to adjust the pH to 10, and continue stirring for 5 hours to obtain the precipitate B;

[0037] (5) Wash the precipitate B until i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com