Flour processing technology

A processing technology and flour technology, applied in the application, grain processing, grain milling and other directions, can solve the problem that the quality and flour yield of strong gluten wheat flour cannot be balanced, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

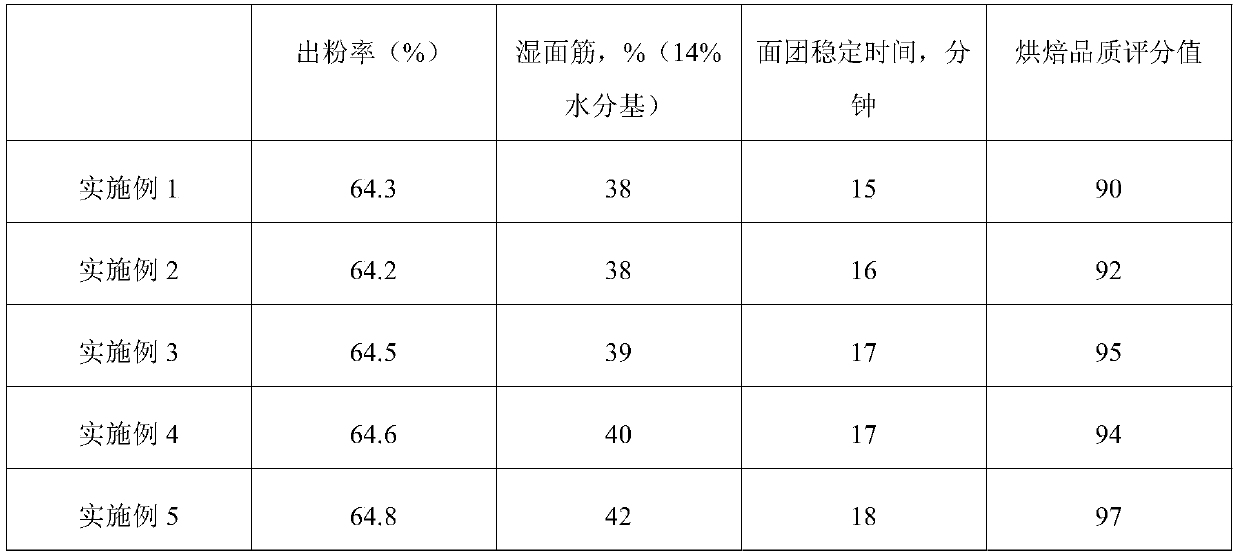

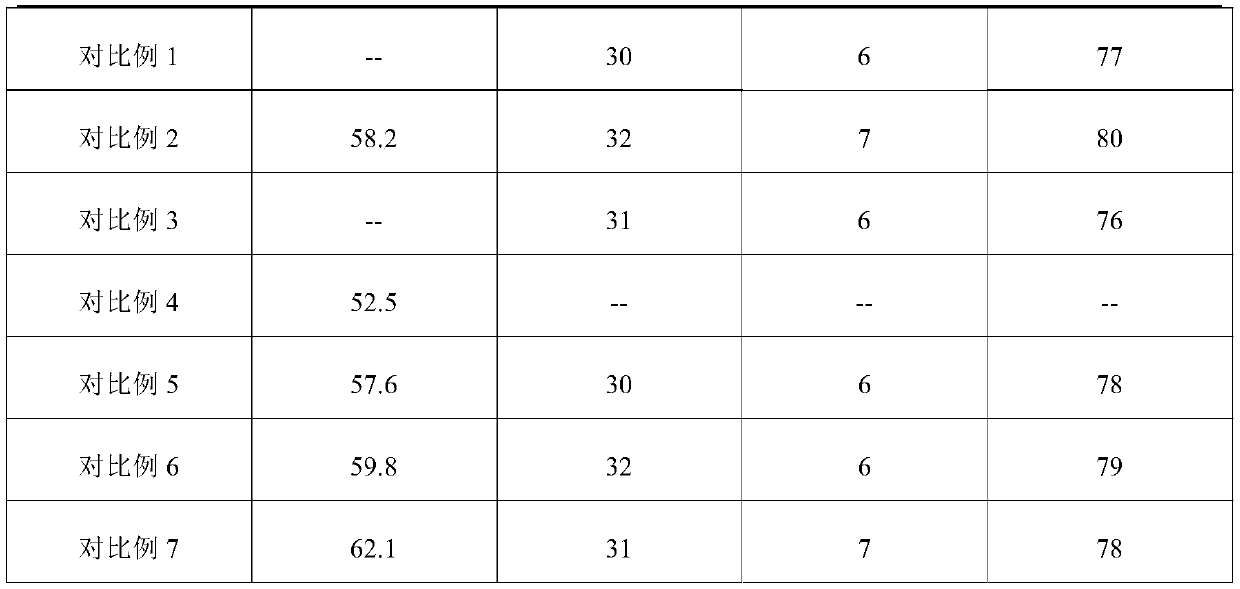

Examples

Embodiment 1

[0036] A kind of flour processing technology, concrete steps are as follows:

[0037] (1) First, carry out 121°C steam explosion treatment on the cleaned and de-impured strong gluten wheat, the explosion pressure is 1.2MPa, and the treatment time is 5s;

[0038] (2) freeze-drying, then utilize the peeling machine to carry out the peeling process, finish peeling when the peeling weight accounts for 7% of the total weight before peeling, and obtain the peeled wheat grains;

[0039] (3) Then the peeled wheat grains are placed in an anaerobic airtight environment, and the mixed solution is continuously flowed through the airtight environment in the form of spray, during which the peeled wheat grains are in a state of continuous stirring;

[0040] (4) Air-dry, take out and grind to obtain high-gluten flour.

[0041]Wherein, the mixed solution is prepared by mixing the mixed water extract of Jerusalem artichoke tubers and agaricus with phospholipids and water according to the mass ...

Embodiment 2

[0059] A kind of flour processing technology, concrete steps are as follows:

[0060] (1) First, the cleaned and de-impured strong gluten wheat is subjected to steam explosion treatment at 126°C, the explosion pressure is 1.4MPa, and the treatment time is 8s;

[0061] (2) freeze-drying, then utilize the peeling machine to carry out the peeling process, when the peeling weight accounts for 9% of the total weight before peeling, finish the peeling, and obtain the peeled wheat grains;

[0062] (3) Then the peeled wheat grains are placed in an anaerobic airtight environment, and the mixed solution is continuously flowed through the airtight environment in the form of spray, during which the peeled wheat grains are in a state of continuous stirring;

[0063] (4) Air-dry, take out and grind to obtain high-gluten flour.

[0064] Wherein, the mixed solution is prepared by mixing the mixed water extract of Jerusalem artichoke tubers and agaricus, phospholipids and water according to t...

Embodiment 3

[0082] A kind of flour processing technology, concrete steps are as follows:

[0083] (1) First, the cleaned and de-impured strong gluten wheat is subjected to steam explosion treatment at 121°C, the explosion pressure is 1.4MPa, and the treatment time is 5s;

[0084] (2) freeze-drying, then utilize the peeling machine to carry out the peeling process, when the peeling weight accounts for 9% of the total weight before peeling, finish the peeling, and obtain the peeled wheat grains;

[0085] (3) Then the peeled wheat grains are placed in an anaerobic airtight environment, and the mixed solution is continuously flowed through the airtight environment in the form of spray, during which the peeled wheat grains are in a state of continuous stirring;

[0086] (4) Air-dry, take out and grind to obtain high-gluten flour.

[0087] Wherein, the mixed solution is prepared by mixing the mixed water extract of Jerusalem artichoke tubers and agaricus with phospholipids and water according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com