Planning polishing method for curved surface of special-shaped stone based on robot

A robot and curved surface technology, applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems that the robot polishing system is difficult to realize and the planning trajectory is single, so as to reduce the harm of noise and dust to people and improve The effect of high overall quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

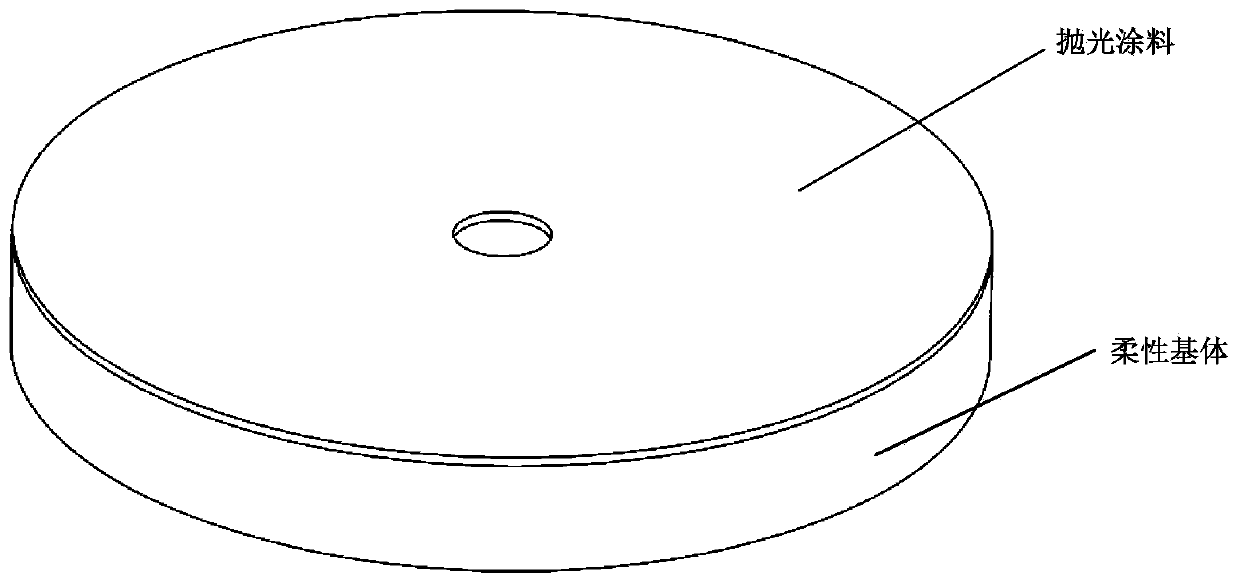

[0028] (1) Choose a flexible polishing disc with a suitable degree of hardness, such as figure 1 As shown, the flexible substrate of the flexible polishing disc has a Shore hardness of 45HSA, a diameter of 100mm and a thickness of 20mm, and is cylindrical. The surface of the flexible polishing disc is semi-consolidated with a diamond abrasive of W40 grain size through a gel. ;

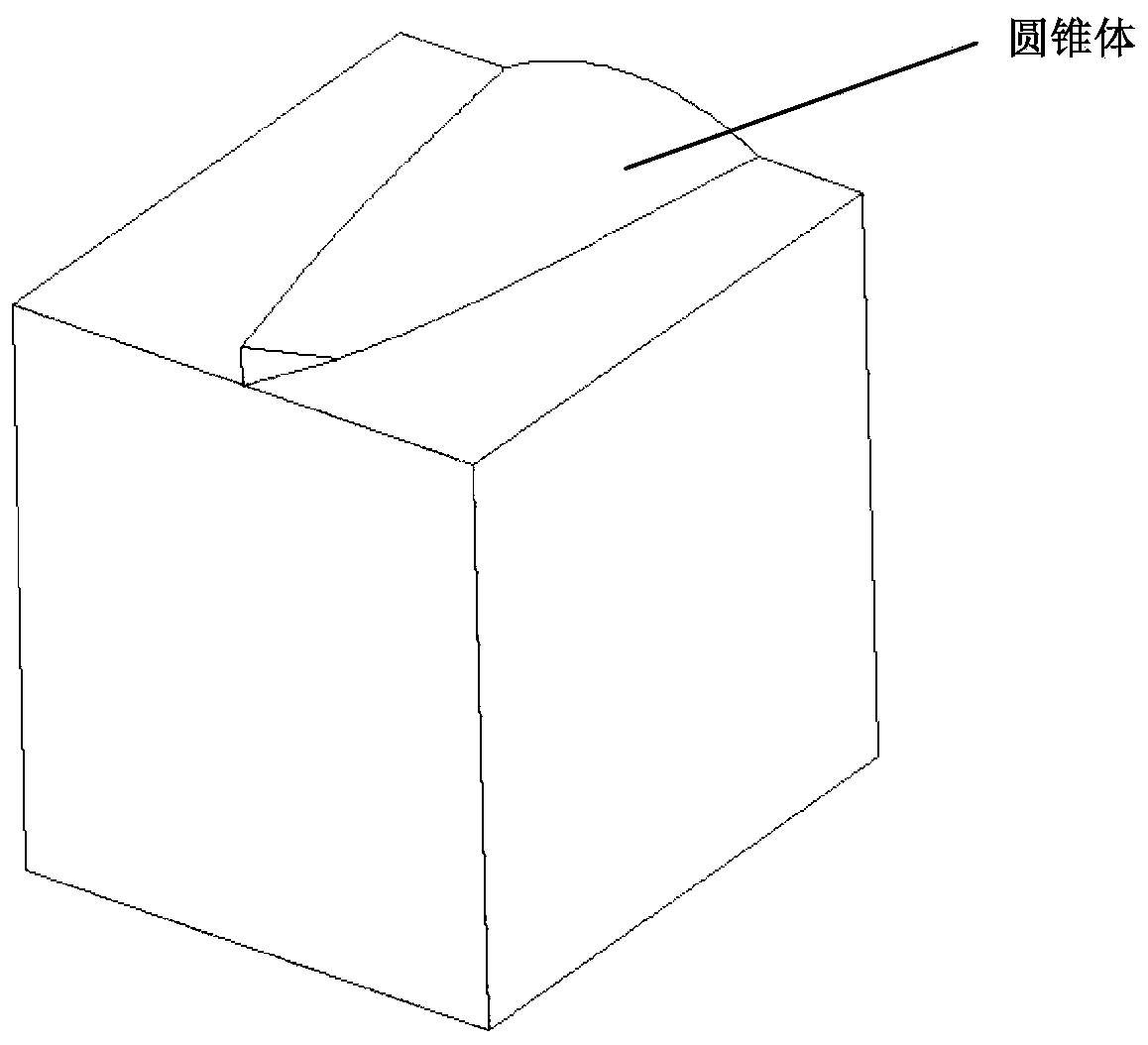

[0029] (2) Prepare as figure 2 The polishing workpiece shown includes a base and a surface to be polished. The base is cubic, the surface to be polished is provided on the top surface thereof, and the surface to be polished is a partial side wall of a cone. The top angle of the cone is 50°, the length of the generatrix is 223mm, and the radius of the bottom circle is 100mm. The uppermost generatrix of the cone where this part of the side wall is located is parallel to the upper surface of the base, and the uppermost generatrix is connected to the base. The distance between the top surface of the seat...

Embodiment 2

[0034] Steps (1) to (4) are the same as in Example 1

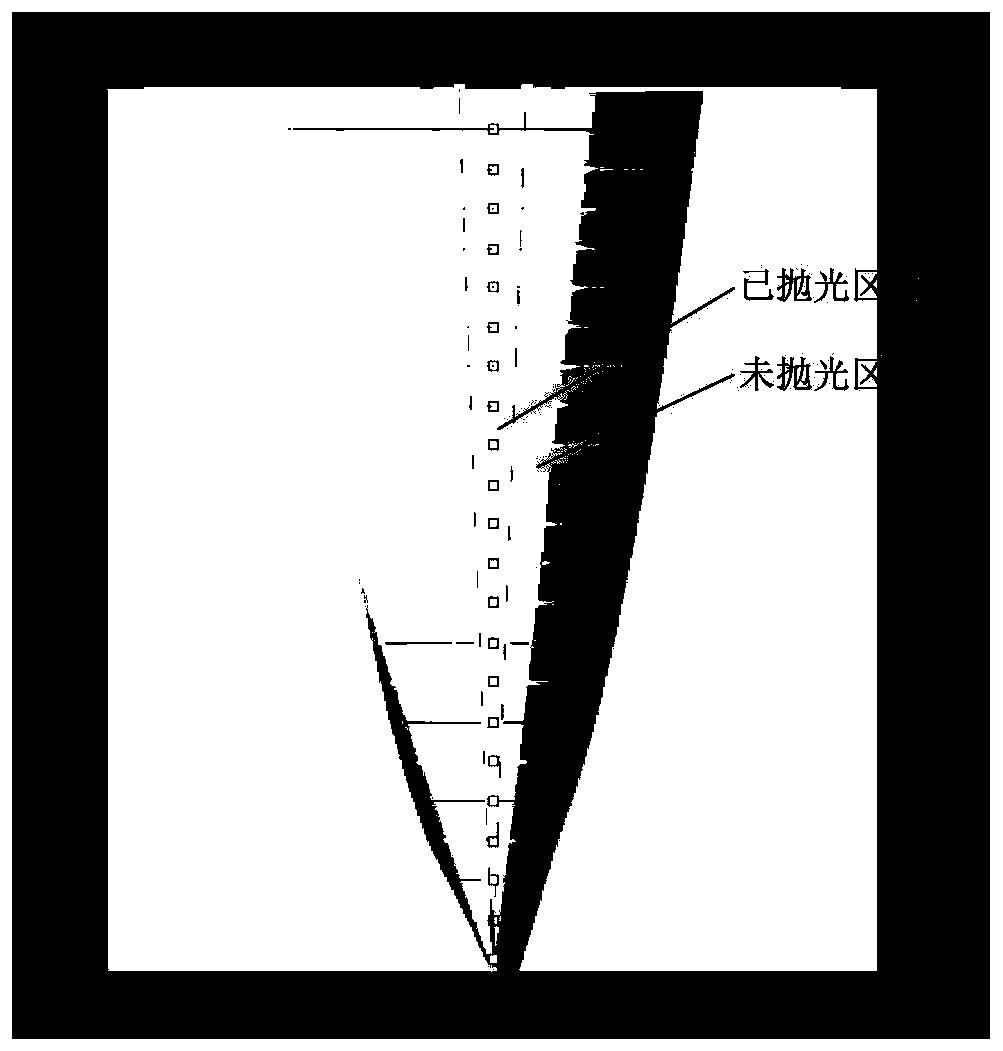

[0035] (5) According to Image 6 The surface characteristics of the surface of the special-shaped stone to be polished are partitioned: by observing the changes in the surface morphology, the surface of the special-shaped stone to be polished is divided into the front area, the back area, the middle area, the middle area and the middle area. Zone 3 and Zone 4;

[0036] (6) The front area and the back area are relatively flat, and the soft characteristics of the flexible polishing disc can be used to fit together, and the trajectory planning is carried out according to the plane. To ensure full coverage of the area, the distance between the tracks is about one-third of the diameter of the flexible polishing disc d=30mm; Import the surface of the special-shaped stone to be polished into the three-dimensional modeling software Rhino to generate a curvature cloud map, and take 10 points at each area where the curvature cloud map sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com