Graphene modified concrete retarder and preparation method thereof

A technology of graphene modification and retarder, which is applied in the field of concrete admixtures, can solve the problems of low early strength of concrete, achieve good retardation effect, improve frost resistance performance, and improve the effect of later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

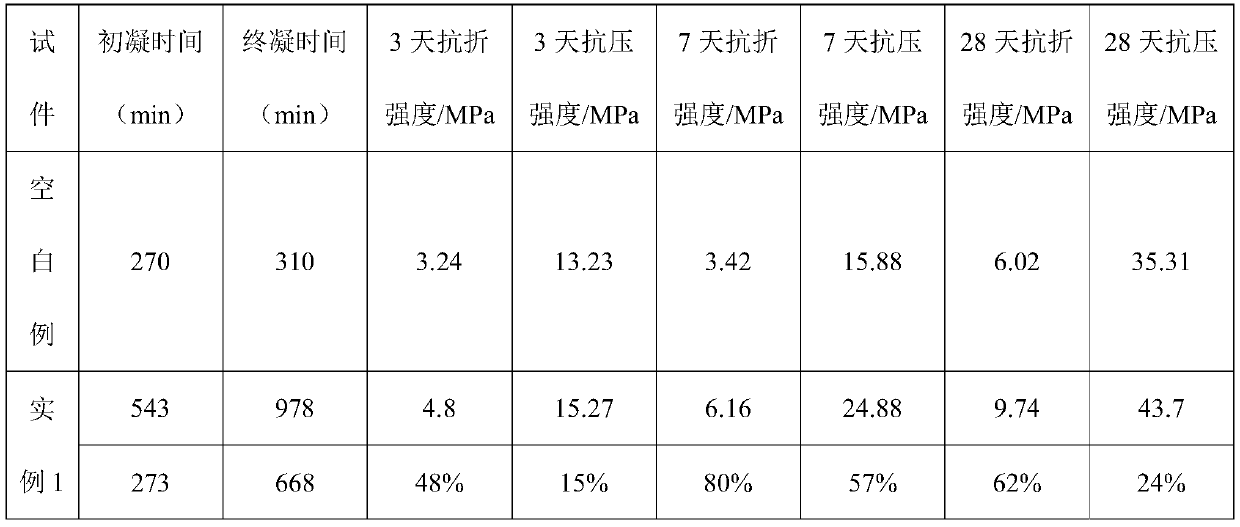

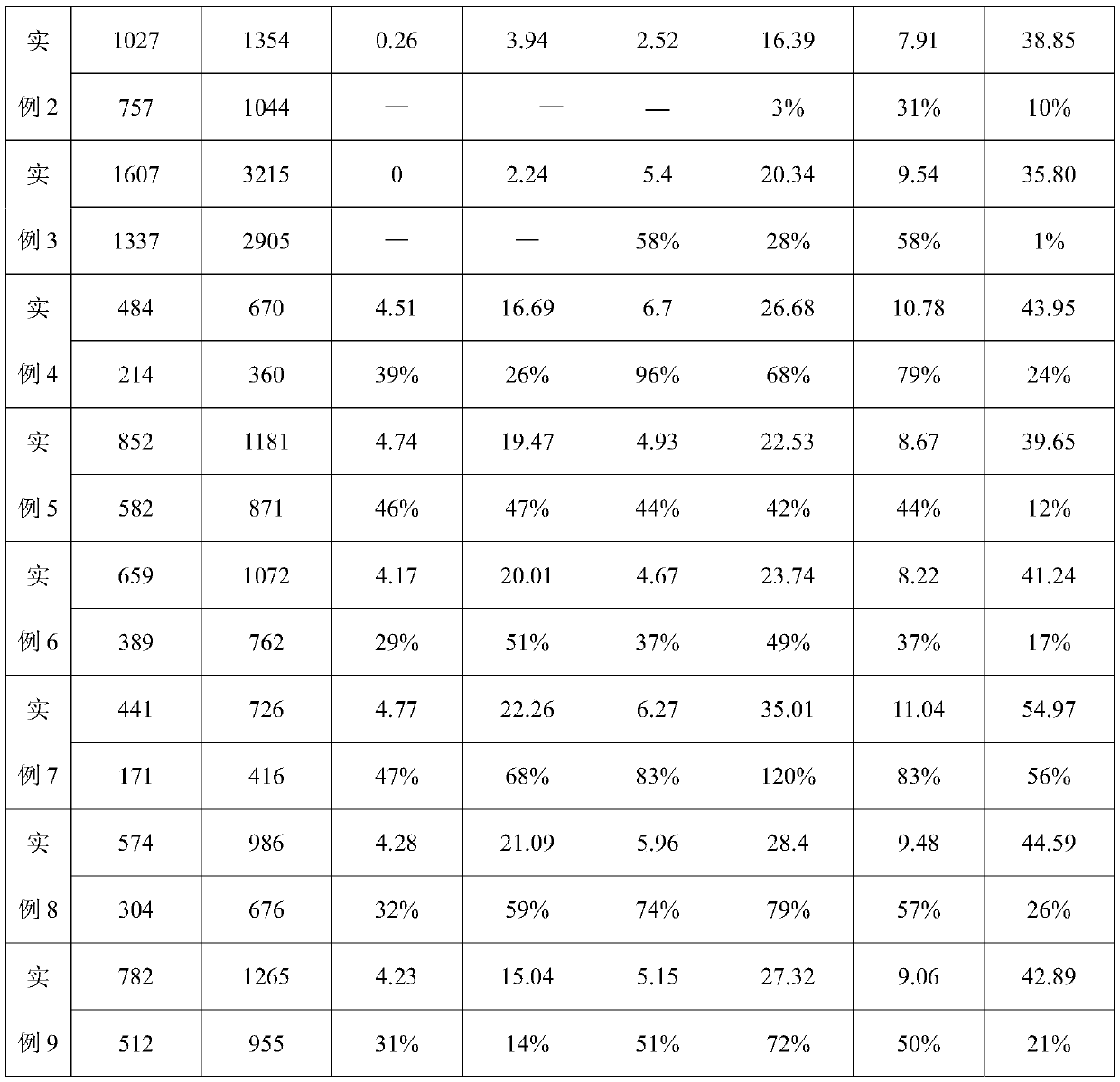

Embodiment 1

[0022] A graphene modified concrete retarder, comprising the following components in parts by weight: 30 parts of graphene, 25 parts of tetrasodium edetate, 20 parts of calcium formate, 15 parts of calcium bromide, 10 parts of urea .

[0023] Preparation method: mix tetrasodium edetate and graphene evenly, add to 200ml of water, stir at 400-600rpm for 2min, and then ultrasonically disperse for 6min to obtain the mixture. The obtained mixture is mixed with calcium bromide, urea and calcium formate and ground evenly.

Embodiment 2

[0025] A graphene-modified concrete retarder, comprising the following components in parts by weight: 30 parts of graphene, 20 parts of tetrasodium edetate, 15 parts of calcium formate, 15 parts of calcium bromide, 20 parts of urea .

[0026] Preparation method: mix tetrasodium edetate and graphene evenly, add to 200ml of water, stir at 400-600rpm for 2min, and then ultrasonically disperse for 6min to obtain the mixture. The obtained mixture is mixed with calcium bromide, urea and calcium formate and ground evenly.

Embodiment 3

[0028] A graphene modified concrete retarder, comprising the following components in parts by weight: 35 parts of graphene, 15 parts of tetrasodium edetate, 15 parts of lithium formate, 15 parts of calcium bromide, 20 parts of urea .

[0029] Preparation method: mix tetrasodium edetate and graphene evenly, add to 200ml of water, stir at 400-600rpm for 2min, and then ultrasonically disperse for 6min to obtain the mixture. Mix and grind the obtained mixture with calcium bromide, urea and lithium formate evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com