Branched polyamino long-chain alkyl polysiloxane and waterproof soft organosilicon finishing agent, and preparation methods thereof

A technology of polyamino long-chain alkyl polysiloxane and long-carbon chain alkyl diethoxysilane is applied in the field of organosilicon finishing agents, which can solve the problems of easy delamination, poor stability, white spots, etc. Excellent waterproofing agent, excellent softness, and the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of branched polyamino long-chain alkylpolysiloxane: 500g octamethylcyclotetrasiloxane, 20g methyloctadecyldiethoxysilane, 5g gamma-diethylenetriaminepropylmethyldimethoxysilane Add methoxysilane into the reaction vessel, at 80°C, under the action of basic catalyst potassium hydroxide (0.1g), prepolymerize for 0.5h, react under vacuum for 3h, add 1.5g of methyltriethoxy Silane, obtained after vacuum decompression reaction for 0.5h;

[0041] Compound branched polyamino long-chain alkyl polysiloxane and 56°C melting point paraffin at a mass ratio of 1:0.1, and heat to 60°C to obtain mixture I;

[0042] Add 1% AEO-7, 3% TO-3, 8% IPL-1005, 1% 1231 mixed emulsifier of the mass of mixture I, stir at 60°C for 30min, slowly add water dropwise until the solid content of the emulsion is 32%, and the waterproof Soft silicone finishing agent T732.

Embodiment 2

[0044] Preparation of branched polyamino long-chain alkylpolysiloxane: 500g octamethylcyclotetrasiloxane, 10g methyl octadecyldiethoxysilane, 15g gamma-diethylenetriaminepropylmethyl Dimethoxysilane was added to the reaction vessel, and at 80°C, under the action of the basic catalyst potassium hydroxide (0.1g), the prepolymerization reaction was performed for 1 hour, and the vacuum decompression reaction was carried out for 9 hours, and 0.5g of methyl triethoxy was added. Silane can be obtained by vacuum decompression reaction for 1h;

[0045] Compound branched polyamino long-chain alkyl polysiloxane and 56°C melting point paraffin at a mass ratio of 1:0.2, and heat to 60°C to obtain mixture I;

[0046] Add 2% AEO-7, 6% TO-3, 8% IPL-1005, 1% 1831 mixed emulsifier of the mass of mixture I, stir at 60°C for 30min, slowly add water dropwise until the solid content of the emulsion is 32%, and the waterproof Soft silicone finishing agent T732.

Embodiment 3

[0048]Preparation of branched polyamino long-chain alkylpolysiloxane: 500g octamethylcyclotetrasiloxane, 10g methyl octadecyldiethoxysilane, 15g gamma-diethylenetriaminepropylmethyl Add dimethoxysilane into the reaction vessel, at 80°C, under the action of basic catalyst potassium hydroxide (0.1g), prepolymerize for 1h, react under vacuum for 9h, add 2g of methyltriethoxysilane , vacuum decompression reaction 0.5h that is;

[0049] Compound branched polyamino long-chain alkyl polysiloxane and 60°C melting point paraffin in a mass ratio of 1:1, and heat to 60°C to obtain mixture I;

[0050] Add 10% AEO-7, 6% TO-3, 10% IPL-1005, and 1% 1631 mixed emulsifier of the mass of mixture I, stir at 60°C for 30 minutes, and slowly add water until the solid content of the emulsion is 32%. Soft silicone finishing agent T732.

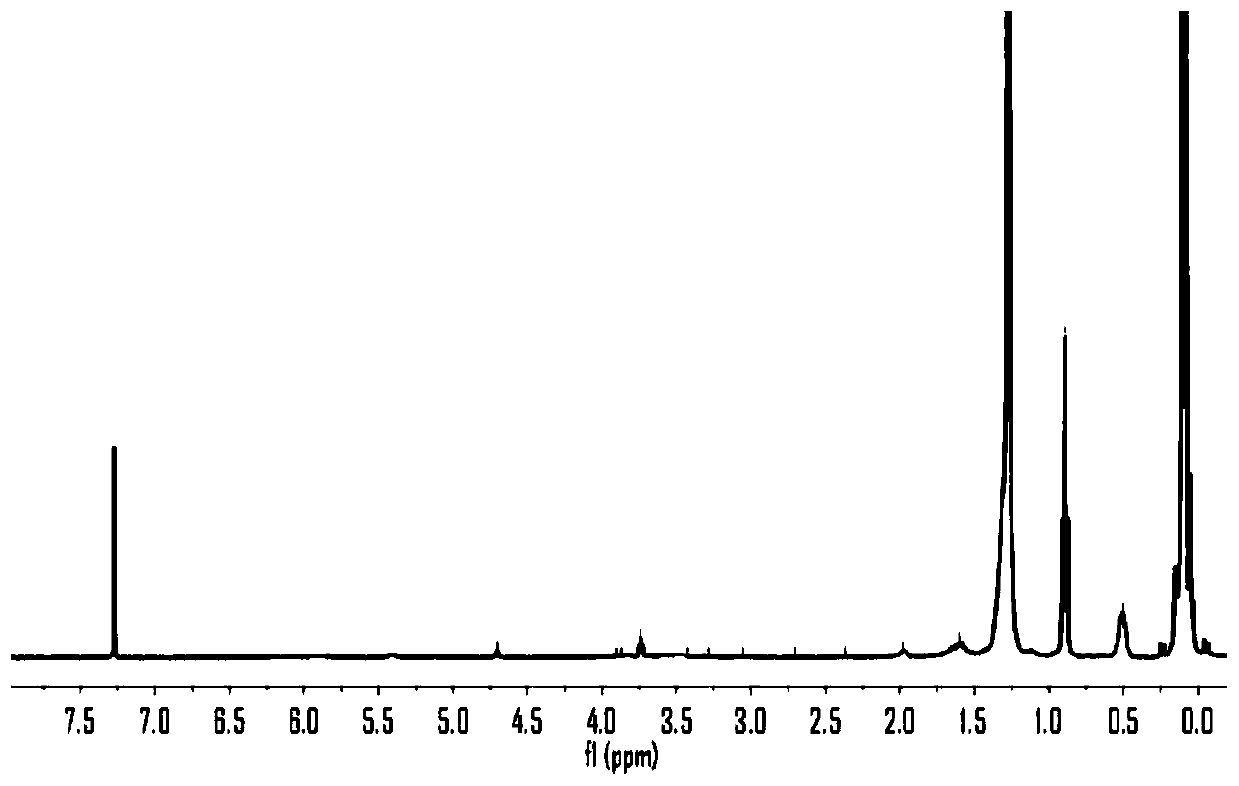

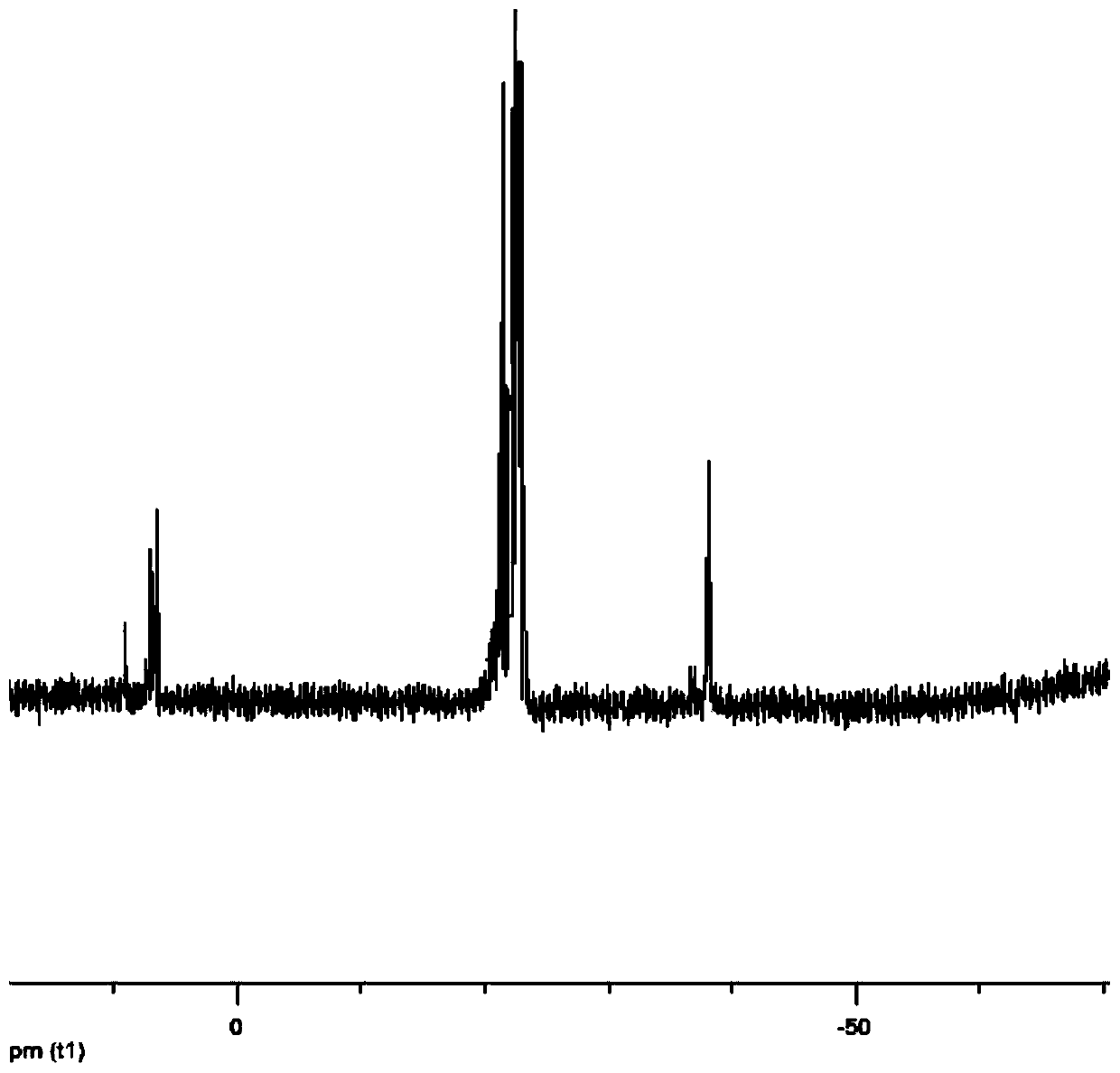

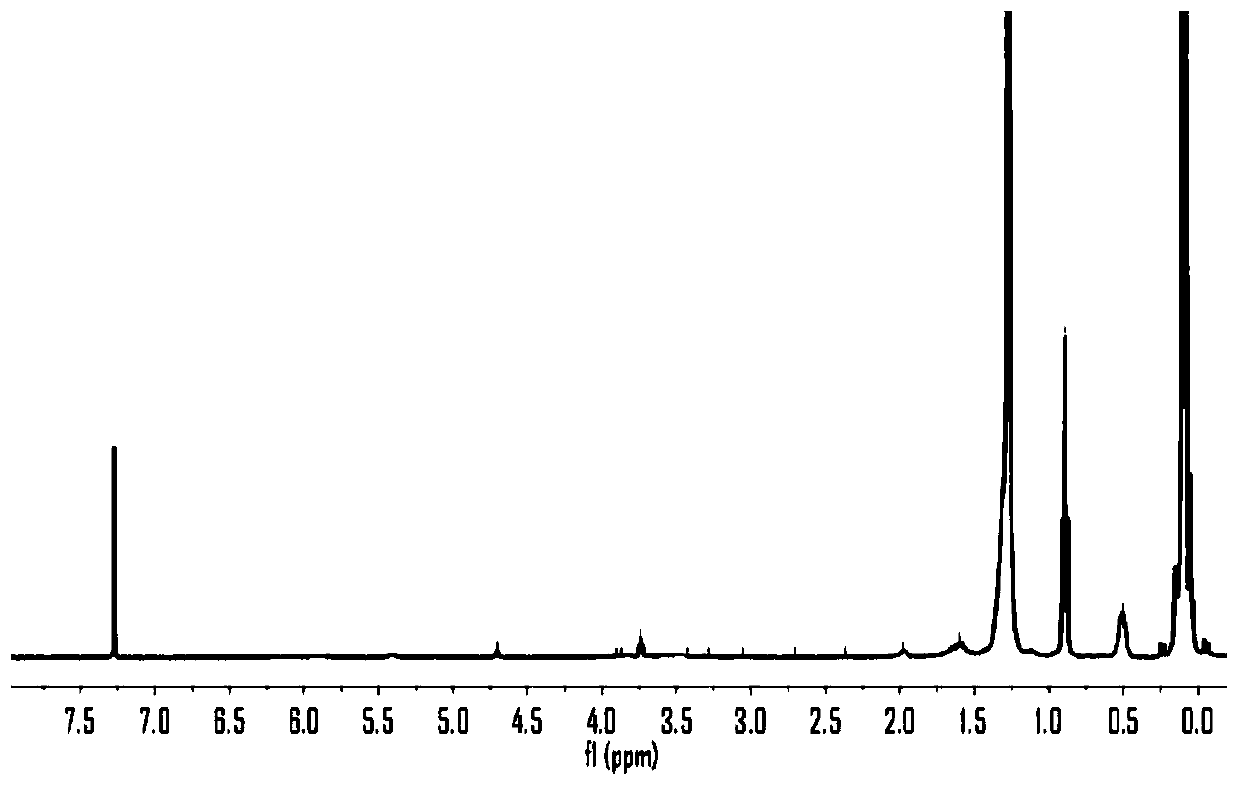

[0051] Chemical characteristics and characterization of waterproof and soft silicone finishing agent T732:

[0052] Appearance: Observe directly with naked eyes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com