A preparation method for laser 3D printing metal-ceramic composite powder

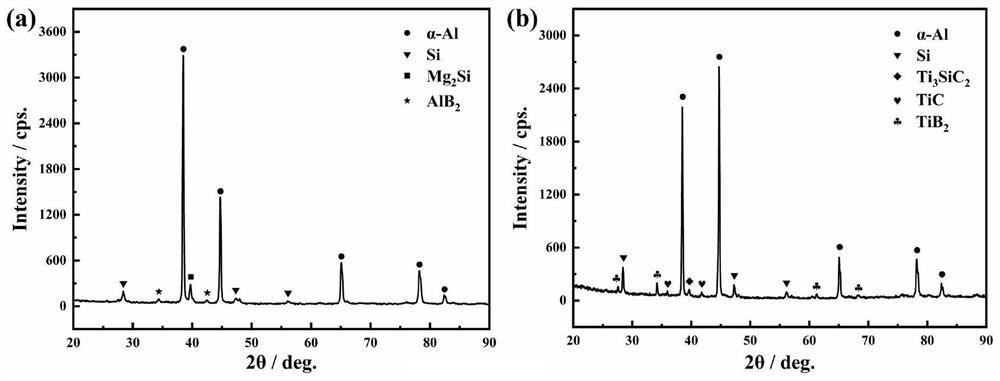

A 3D printing and cermet technology, applied in metal processing equipment, additive manufacturing, additive processing, etc., can solve the problems of low in-situ synthesis chemical reaction rate and in-situ synthesis failure, and achieve excellent high-temperature oxidation resistance, The effect of uniform dispersion distribution combination, uniform and dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

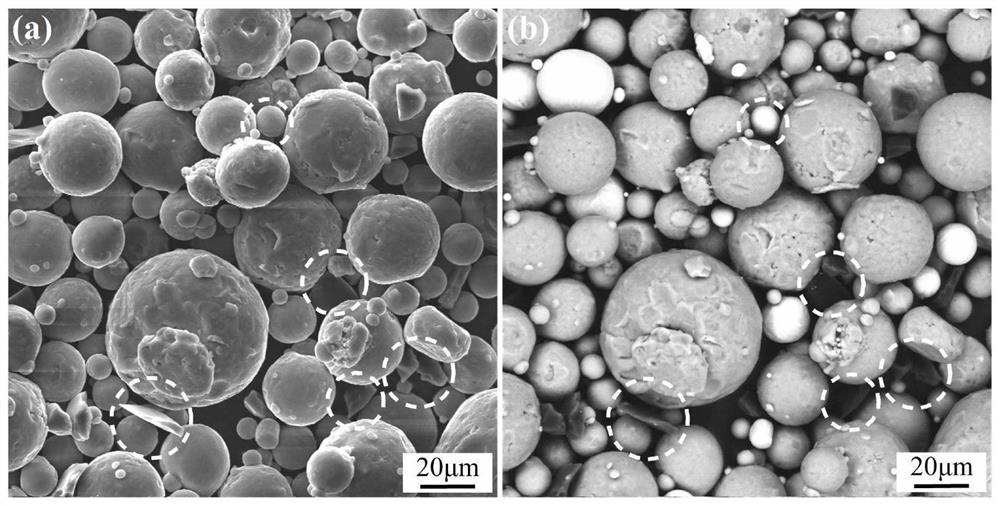

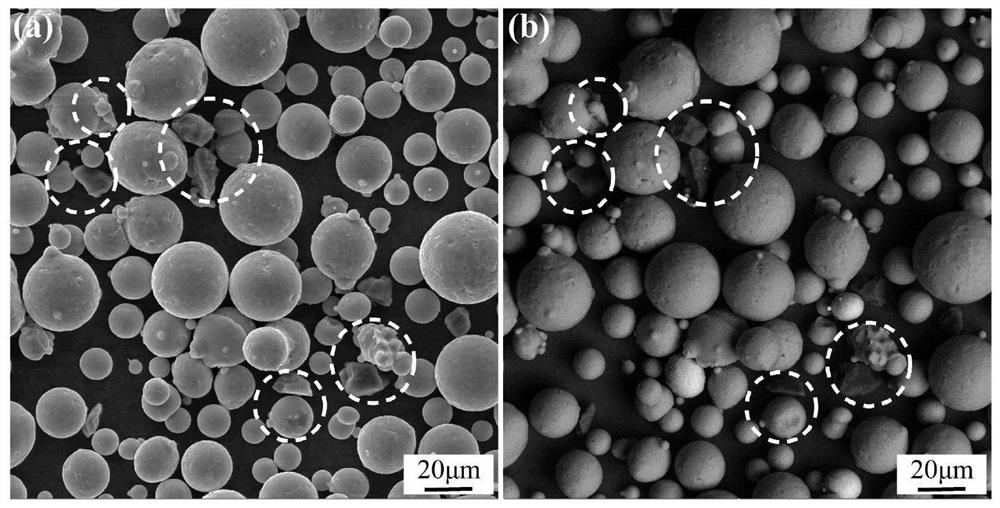

[0025] A preparation method for laser 3D printing metal-ceramic composite powder, specifically comprising the following steps:

[0026] (1) According to the mass ratio m(Ti):m(B 4 C)=2.6:1, take by weighing the pure Ti powder and pure B preserved in vacuum seal 4 C powder is compounded; the Ti powder is a spherical particle with a particle size of 20 μm, and the purity is not less than 99.99%; the B 4 C powder is an amorphous angular ceramic particle with an equivalent particle size of 15 μm, and the purity is not lower than 99.99%.

[0027] (2) PVA binder solution: take by weighing a beaker with a mass fraction of 5% PVA particles and 95% deionized water, then use a magnetic stirrer to fully stir it to prepare the PVA binder solution, the magnetic stirrer The stirring speed is 40rpm, the stirring time is 30min, and the temperature of the PVA solution is stirred to 90°C.

[0028] (3) in Ti / B 4 Add PVA binder solution to the mixed powder of C, wherein, the mass fraction of ...

Embodiment 2

[0031] A preparation method for laser 3D printing metal-ceramic composite powder, specifically comprising the following steps:

[0032] (1) According to the mass ratio m(Ti):m(B 4 C)=2.6:1, weigh the pure Ti powder and pure B 4 C powder is used for compounding, the Ti powder is a spherical particle with a particle size of 13.5 μm, and the purity is not less than 99.99%; the B 4 C powder is an amorphous angular ceramic particle with an equivalent particle size of 10 μm, and the purity is not lower than 99.99%.

[0033] (2) PVA binder solution: use a beaker to weigh 7% PVA particles and 93% deionized water with a beaker, then use a magnetic stirrer to fully stir it to prepare the PVA binder, the magnetic stirrer The parameter setting is consistent with that in Example 1.

[0034] (3) in Ti / B 4 Add PVA binder solution to the mixed powder of C, wherein, the mass fraction of PVA binder solution is 15%, Ti / B 4 The mass fraction of the C mixed powder is 85%, and it is stirred ev...

Embodiment 3

[0037] A preparation method for laser 3D printing metal-ceramic composite powder, specifically comprising the following steps:

[0038] (1) According to the mass ratio m(Ti):m(B 4 C)=2.6:1, weigh the pure Ti powder and pure B 4 C powder is used for compounding, the Ti powder is a spherical particle with a particle size of 10 μm, and the purity is not less than 99.99%; the B 4 C powder is an amorphous angular ceramic particle with an equivalent particle size of 5 μm, and the purity is not lower than 99.99%.

[0039] (2) PVA binder solution: take by weighing a beaker with a mass fraction of 10% PVA particles and 90% deionized water, then use a magnetic stirrer to fully stir it to prepare the PVA binder, the magnetic stirrer The parameter setting is consistent with that in Example 1.

[0040] (3) in Ti / B 4 Add PVA binder solution to the mixed powder of C, wherein, the mass fraction of PVA binder solution is 15%, Ti / B 4 The mass fraction of the C mixed powder is 85%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com