Synchronous control method for load-deflection resistance of servo pump

A technology of synchronous control and servo pump, which is applied in the field of forging and press manufacturing, and can solve the problems of not considering the oil pressure characteristics of the pump control system, and the synchronization performance of the initial contact workpiece section cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

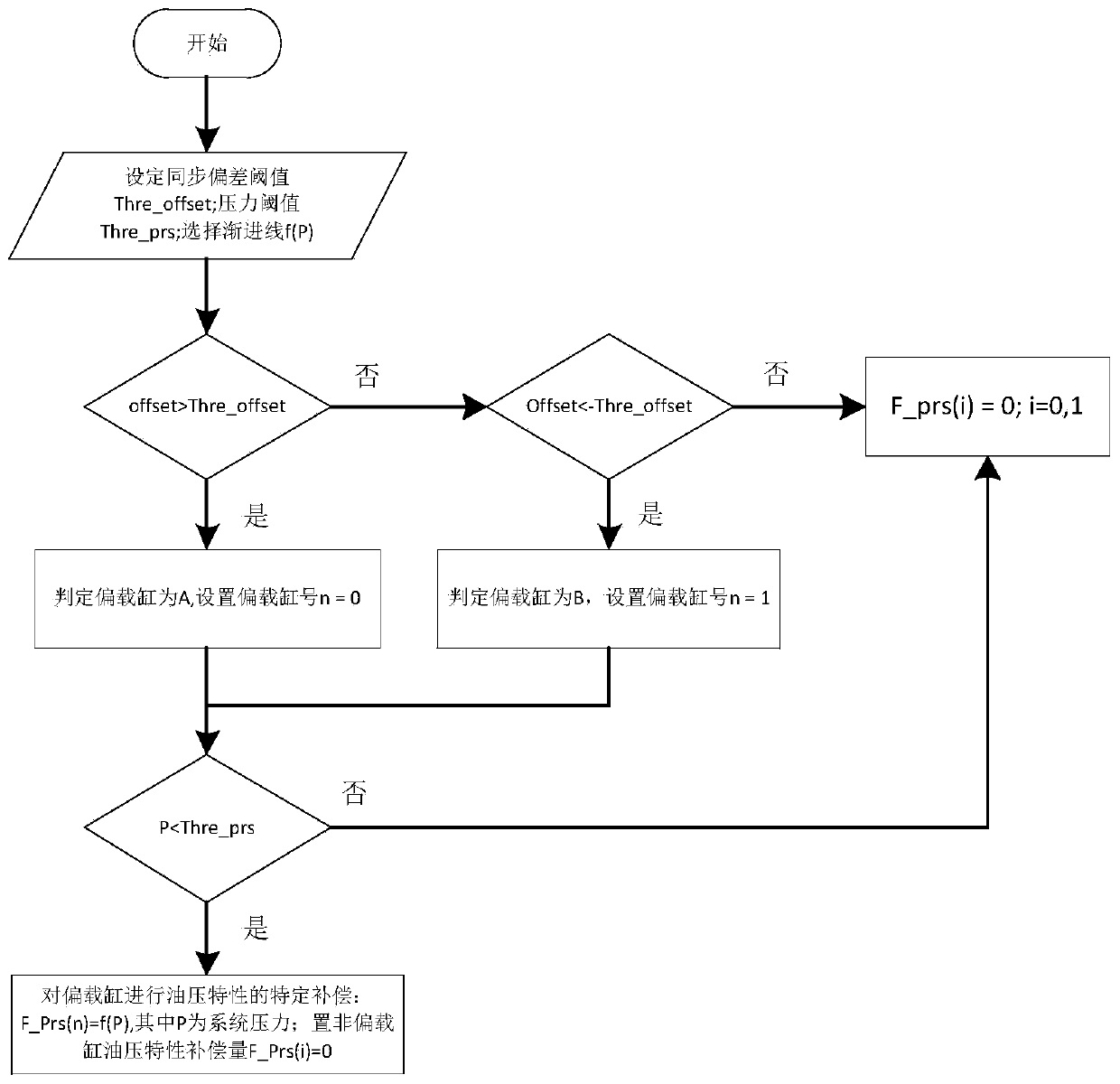

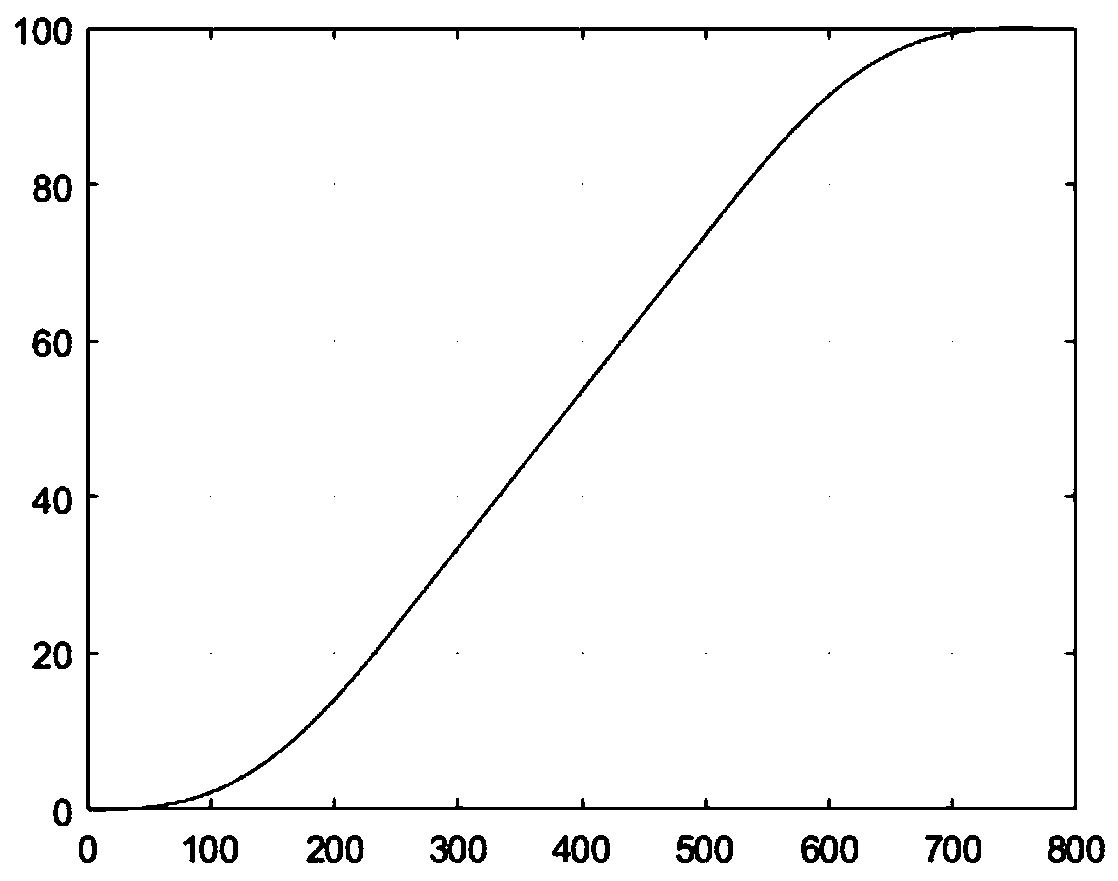

[0020] The servo pump control hydraulic system has the following oil pressure characteristics: due to the compressibility of the oil and the oil circuit itself, when the negative pressure reaches about 3Mpa, real-time pressure cannot be achieved, that is, there is a flow and pressure dead zone, which leads to partial load During the pressing process, the position lag will be caused by the pressure start delay of the partial load cylinder, which will reduce the synchronization performance of multiple cylinders. Accordingly, the present invention proposes a compensation scheme combined with the oil pressure characteristics, which can further improve the synchronous deviation correction capability of the system, especially the initial contact workpiece section, and enhance the robustness of the system.

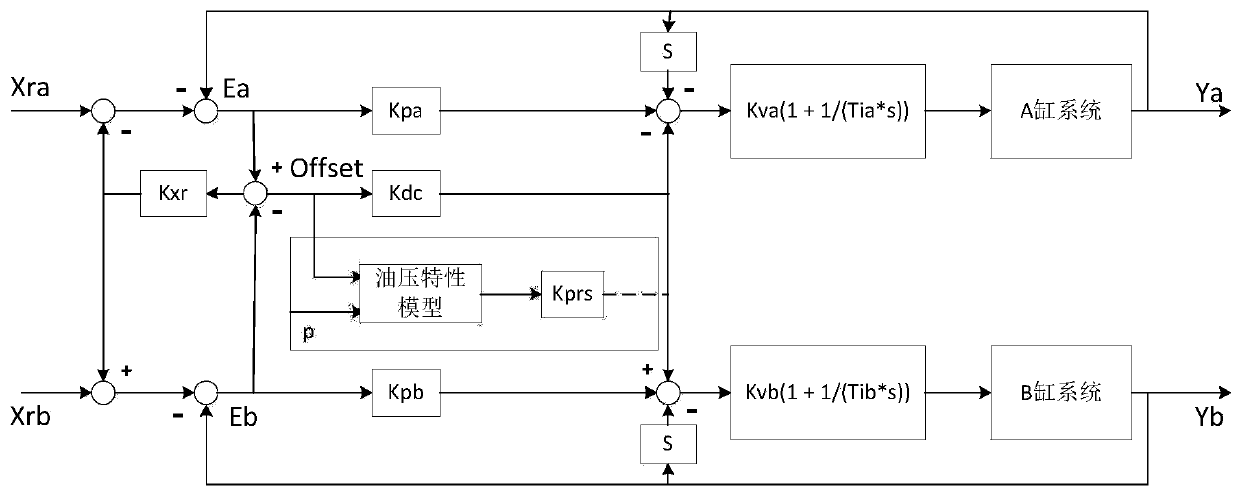

[0021] The present invention aims at the problem of synchronous performance degradation caused by the hydraulic oil and the compressibility of the oil circuit itself, and introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com