Method for manufacturing field oxygen with gradient thickness in trench and method for manufacturing sgt device

A manufacturing method and trench technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems that the BV effect cannot be maximized, the electric field strength cannot be raised, and the electric field distribution cannot be equalized, and the thickness can be achieved. The effect of smooth change, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

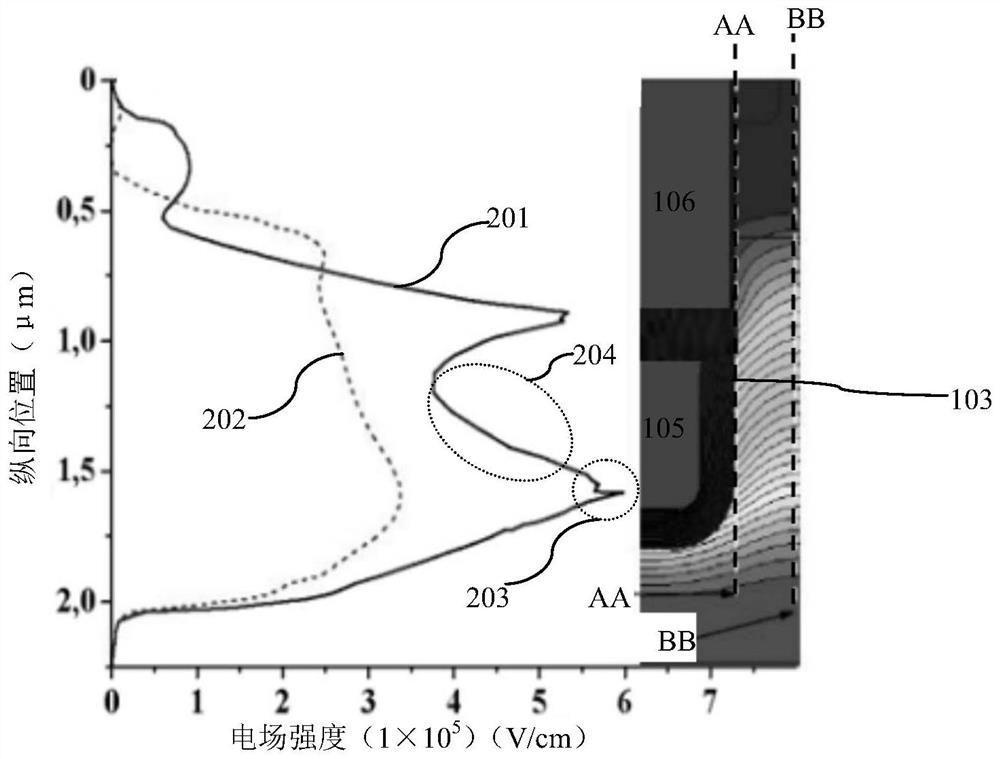

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

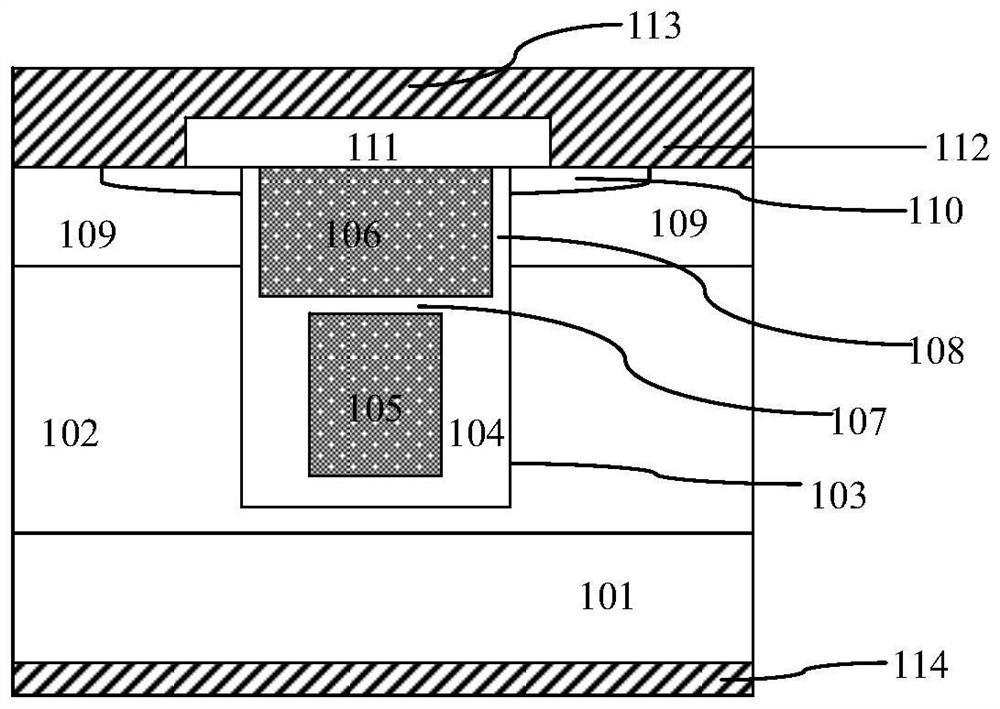

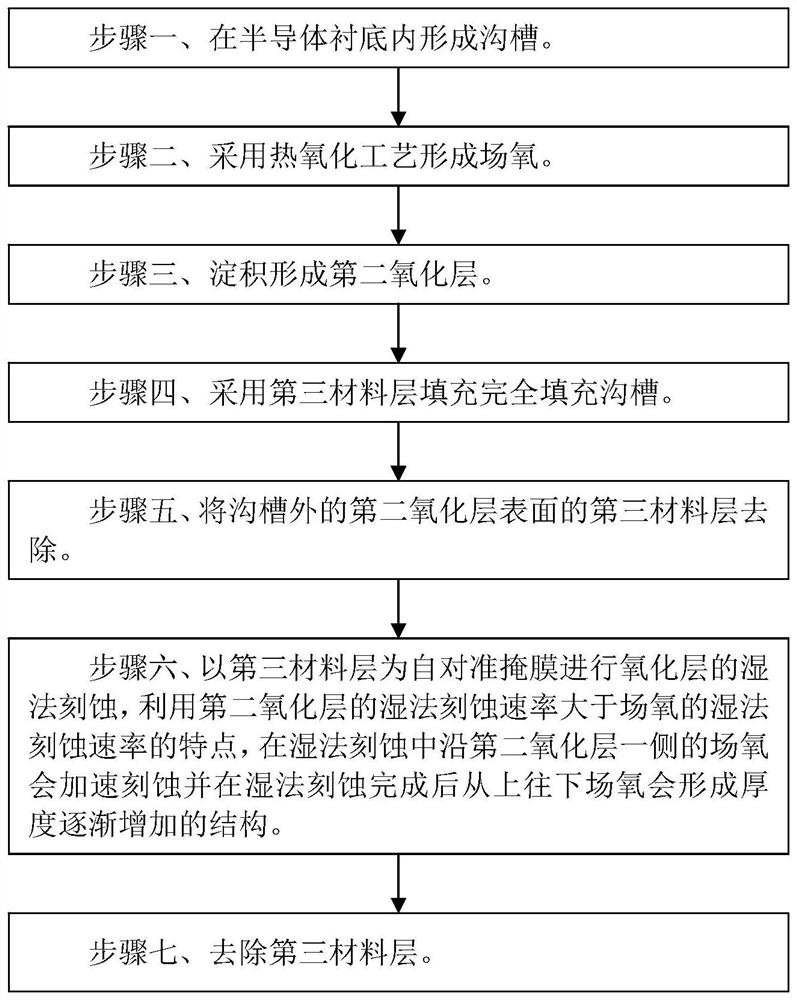

[0068] Step 1, as shown in FIG. 4A , a semiconductor substrate 1 is provided, and trenches 2 are formed in the semiconductor substrate 1 .

[0069] The semiconductor substrate 1 is a silicon substrate.

[0070] Typically, the groove 2 has a side inclination angle of 87.5° to 89°.

[0073] Step 3, as shown in FIG. 4C, a deposition process is used to form a second oxide layer 301, and the second oxide layer 301 is formed

[0074] Both the field oxygen 3 and the second oxide layer 301 are silicon dioxide.

[0075] Preferably, the second oxide layer 301 is formed by a CVD deposition process. CVD deposition process can be sub-atmospheric pressure

[0076] The thickness of the second oxide layer 301 is

[0077] Step 4, as shown in FIG. 4D, using a third material layer 302 to completely fill the trench 2, the third material

[0078] The third material layer 302 is a Barc layer.

[0079] The third material layer 302 is filled into the trench 2 by a coating process.

[0080] Step 5, as sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com