Adjustable optical frequency comb based on lithium niobate microcavity and preparation method thereof

A lithium niobate and microcavity technology, which is applied in optics, lasers, nonlinear optics, etc., can solve the problem of not being able to simultaneously prepare microcavities and integrated electrode structures that can generate optical frequency combs, and achieve the effect of improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

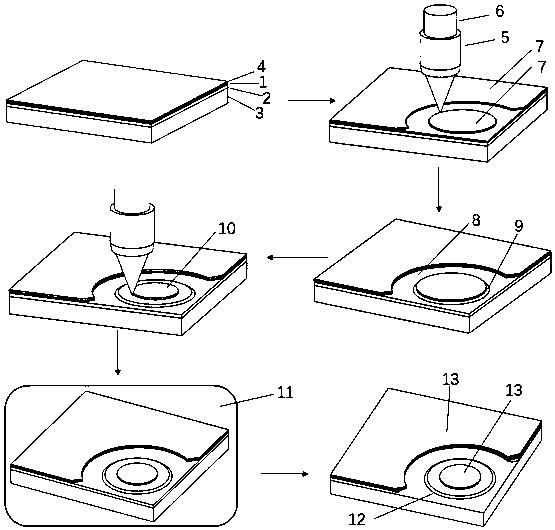

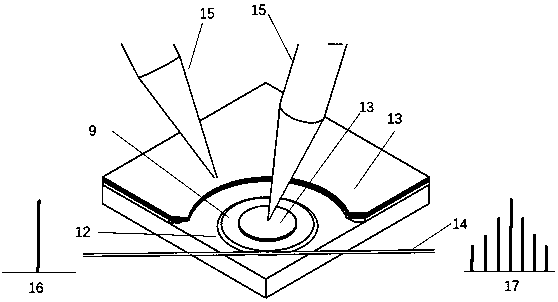

[0031] refer to figure 1 , the preparation method of the present invention comprises the following steps:

[0032] Step 1: Prepare lithium niobate thin film material and chrome-plate it

[0033] The lithium niobate thin film material has three layers: the first layer is a lithium niobate single crystal thin film 1 with a thickness of 900nm; the second layer is a silicon dioxide layer 2 with a thickness of 2 μm; the third layer is a lithium niobate base layer 3 with a thickness of 500 μm. A chromium film layer 4 with a thickness of 600 nm is plated on the surface of the lithium niobate thin film material.

[0034] Step 2: Femtosecond laser direct writing

[0035] The lithium niobate thin film material coated with a chromium film on the surface is fixed on a three-dimensional computer programmable control displacement platform, and a femtosecond laser 6 with a power of 40mW is focused on the said On the chromium film layer 4 on the surface of the thin film material, drive the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com