System and method for rapid scanning test of ICR module

A fast scanning and testing system technology, applied in the direction of electromagnetic receivers, receiver monitoring, etc., can solve the problems of high backup cost, low degree of automation, expensive test equipment, etc., and achieve low requirements for testers, simple maintenance and calibration, and saving The effect of testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

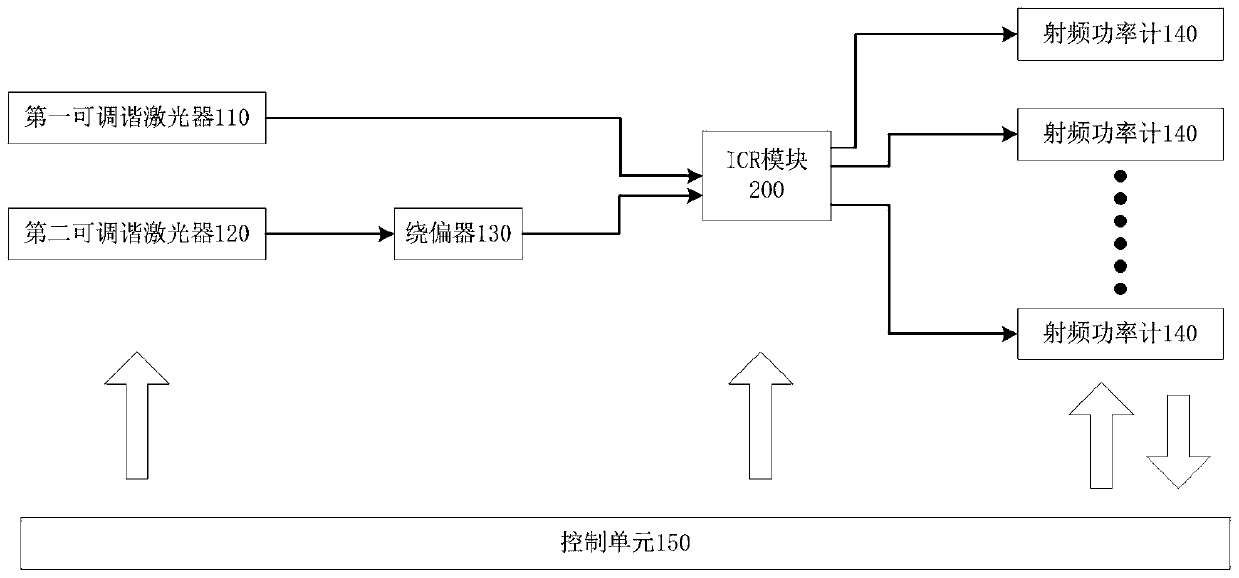

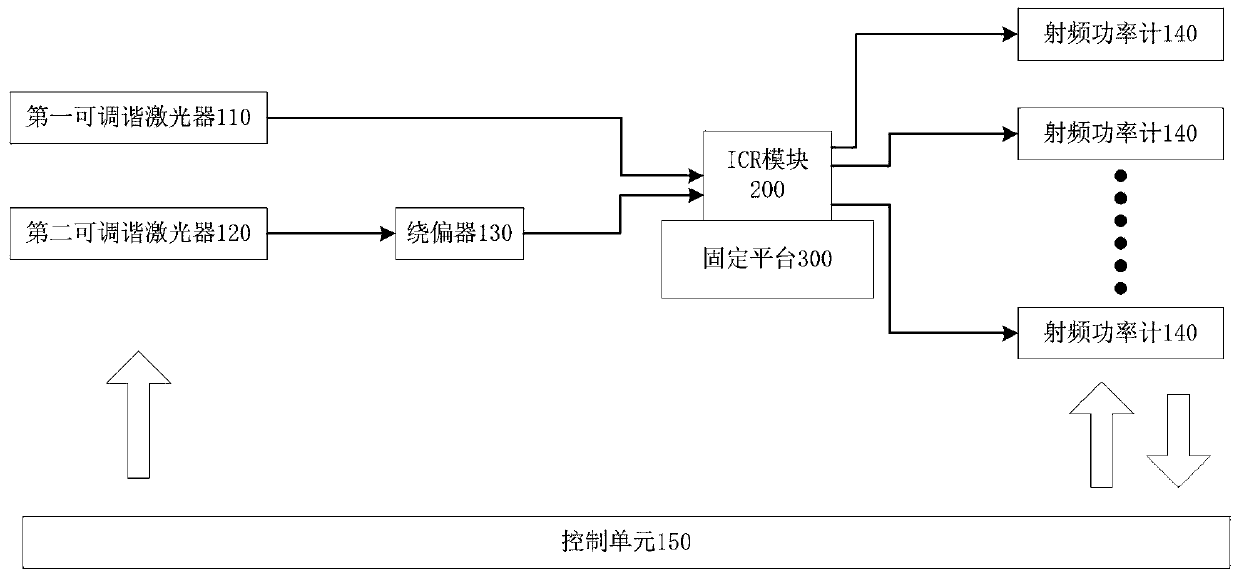

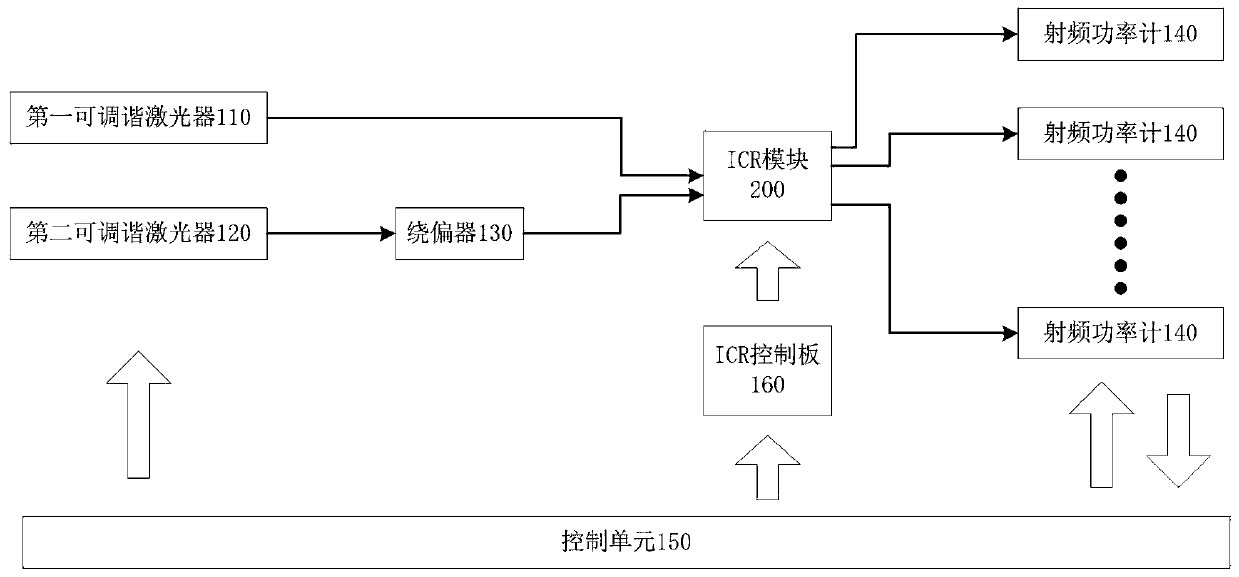

[0033] Such as figure 1 As shown, the present invention provides a preferred embodiment of a rapid scan test system for an ICR module 200 .

[0034] The fast scanning test system includes a first tunable laser 110, a second tunable laser 120, a polarizer 130, a radio frequency power meter 140 and a control unit 150, the input of the first tunable laser 110 and the tested ICR module 200 The second tunable laser 120 communicates with the input terminal of the ICR module 200 under test through the polarizer 130, and a plurality of radio frequency power meters 140 are respectively communicated with a plurality of output channels of the ICR module 200 under test, and the control unit 150 They are respectively connected to the first tunable laser 110 , the second tunable laser 120 , the ICR module 200 and the radio frequency power meter 140 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com