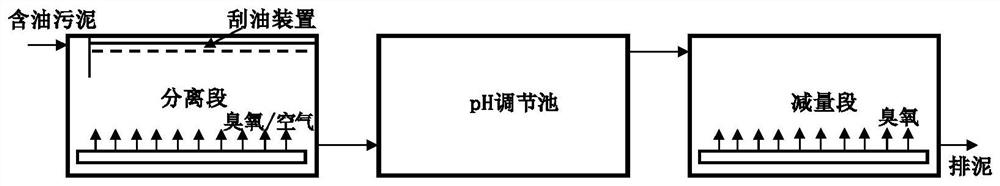

A progressive step-by-step reduction treatment method for oily sludge with micro-nano bubbles and ozone

A technology of micro-nano bubbles and treatment methods, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of environmental secondary pollution, etc., and achieve improved utilization rate, slow rising speed, The effect of increasing dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0039] Two, embodiment 1-7, comparative example 1-3

Embodiment 1

[0041] A step-by-step reduction treatment method for oily sludge with micro-nano bubbles and ozone. The oily sludge produced during the sewage treatment process of a petrochemical company in Shanghai is concentrated by sedimentation and centrifugation, and the concentration of oily sludge is prepared as follows: 28g / L. The ozone condition of micro-nano bubbles in the separation section is that the aeration rate is 0.1m 3 / h, the ozone concentration is 5ppm, and the ozone is passed into the ozone oxidation tank in the form of micro-nano bubbles through the titanium aeration head of 0.45 μm, and the treatment time is 0.5h; the pH value of the oily sludge is adjusted to be reduced to 3.0, and then Carry out micro-nano bubble ozone treatment in the reduction section, the condition is that the aeration rate is 1.0m 3 / h, the ozone concentration is 90ppm, the ozone is passed into the ozone oxidation tank in the form of micro-nano bubbles through the 0.45μm titanium aeration head, an...

Embodiment 2

[0044] A step-by-step reduction treatment method for oily sludge with micro-nano bubbles and ozone. The oily sludge produced during the sewage treatment process of a petrochemical company in Shanghai is concentrated by sedimentation and centrifugation, and the concentration of oily sludge is prepared as follows: 20g / L. The ozone condition of micro-nano bubbles in the separation section is that the aeration rate is 0.1m 3 / h, the ozone concentration is 5ppm, and the ozone is passed into the ozone oxidation tank through the mode of micro-nano bubbles through the titanium aeration head of 0.45 μm, and the treatment time is 0.5h; the pH value of the described oily sludge is adjusted to be reduced to 3.0, and then Carry out micro-nano bubble ozone treatment in the reduction section, the condition is that the aeration rate is 1.0m 3 / h, the ozone concentration is 90ppm, the ozone is passed into the ozone oxidation tank through the 0.45μm titanium aeration head through the way of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com