Functional Daqu for brewing

A functional, Daqu technology, applied in microorganism-based methods, preparation of alcoholic beverages, microorganisms, etc., can solve the problems of low content of tetramethylpyrazine and nucleotides, lack of high-quality liquor in healthy liquor, etc. The effect of good flavor and taste, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

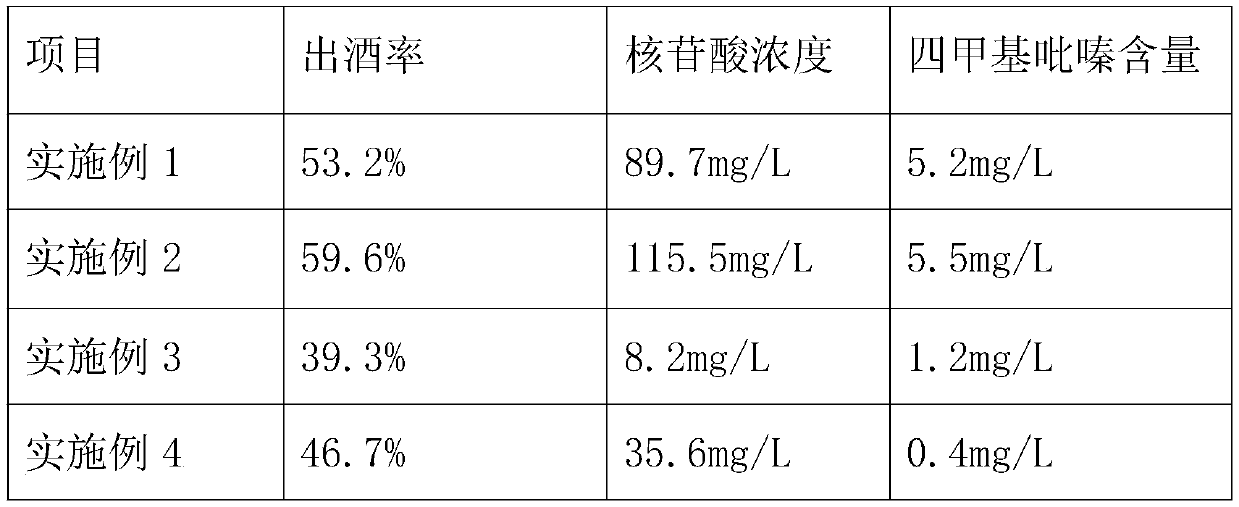

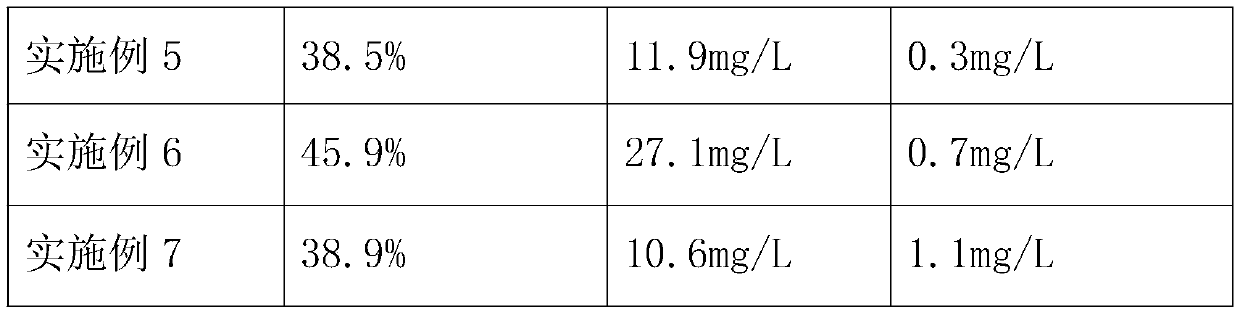

Examples

Embodiment 1

[0038] Strain activation and preparation:

[0039]Rhizopus oryzae: Take a ring of Rhizopus oryzae and inoculate it into the solid medium of Rhizopus oryzae for 24 hours. Pick a single colony with good growth in the plate and inoculate it into the Rhizopus oryzae liquid medium for activation. After culturing for 24 hours, the culture conditions: 30°C, 200r / min, can be used as 5*10 7 (CFU / ml) Rhizopus oryzae seed solution. Rhizopus oryzae solid medium: 1.0L of 5°Bé wort, 15.0g of agar. Rhizopus oryzae liquid medium: 1.0L of 5°Bé wort.

[0040] Yeast: Weigh the preserved Saccharomyces cerevisiae strains and inoculate them into yeast solid medium for 24 hours. Pick a single colony with good growth in the plate and inoculate it into yeast liquid medium for activation. After 24 hours of cultivation, it can be used as 5*10 7 (CFU / ml) yeast seed solution, culture conditions: 30°C, 200r / min. Can be used as Saccharomyces cerevisiae seed solution. Yeast solid medium: 5°Bé wort 1.0L...

Embodiment 2

[0049] The activation and preparation of strains are the same as in Example 1.

[0050] A method for preparing functional Daqu for brewing, the steps are as follows:

[0051] (1) Wheat, trehalose, and water are raw materials for making koji. Firstly, the wheat is crushed through a 20-mesh sieve, and the crushed wheat (65% by mass fraction), trehalose (5% by mass fraction), and water (30% by mass fraction) are stirred together evenly.

[0052] (2) 6% of Rhizopus oryzae liquid (mass fraction of koji-making raw material), 5% of yeast liquid (mass fraction of koji-making raw material), 2% of Bacillus licheniformis liquid (mass fraction of koji-making raw material), Propionibacterium freundii Liquid 1% (mass fraction of koji-making raw materials) is added to the koji-making raw materials, and after being stirred evenly, step on the koji to shape.

[0053] (3) Control the temperature at 45° C. and the humidity at 65%, culture for 40 days, and turn over once every 7 days.

[0054]...

Embodiment 3

[0056] The activation and preparation of strains are the same as in Example 1.

[0057] Contains Rhizopus oryzae, Yeast, Bacillus licheniformis, Propionibacterium freunderi, does not contain trehalose

[0058] A method for preparing functional Daqu for brewing, the steps are as follows:

[0059] (1) Wheat and water are raw materials for koji making. First, the wheat is crushed through a 20-mesh sieve, and the crushed wheat (mass fraction is 70%) and water (mass fraction is 30%) are stirred evenly.

[0060] (2) 5% of Rhizopus oryzae liquid (mass fraction of koji-making raw material), 4% of yeast liquid (mass fraction of koji-making raw material), 1.5% of Bacillus licheniformis liquid (mass fraction of koji-making raw material), Propionibacterium freundii Liquid 1% (mass fraction of koji-making raw materials) is added to the koji-making raw materials, and after being stirred evenly, step on the koji to shape.

[0061] (3) Control the temperature at 42° C. and the humidity at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com