Preparation method for persimmon wine

A technology of persimmon wine and persimmon, which is applied in the field of wine making, can solve the problems of low production capacity and large amount of auxiliary materials, and achieve the effects of increasing production capacity, improving separation effect, and improving wine quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

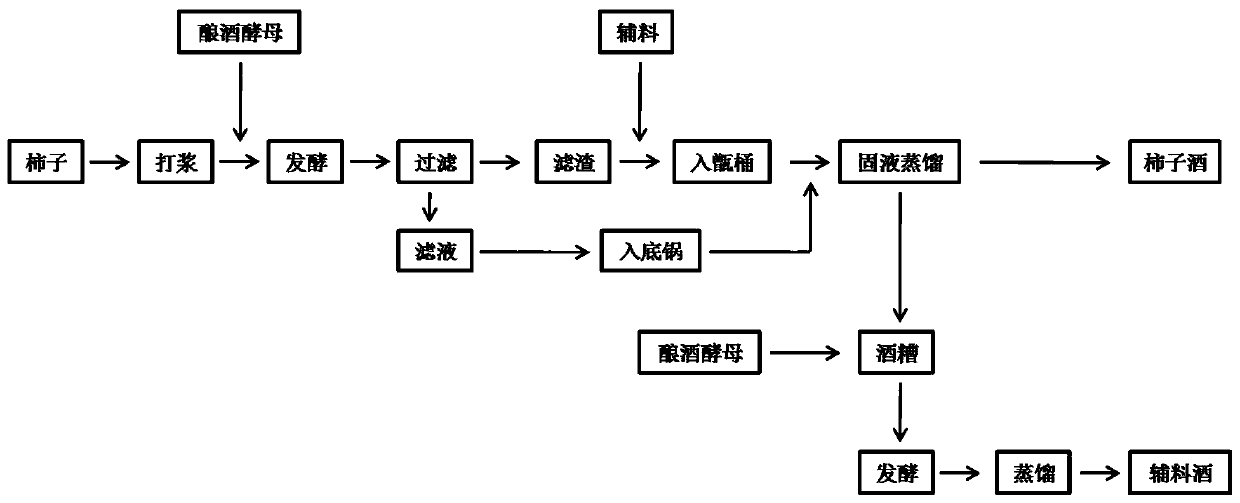

[0026] A preparation method of persimmon wine includes the following steps:

[0027] (1) Raw material pretreatment: 30kg of persimmons are selected and crushed to obtain persimmon pulp;

[0028] (2) Fermentation: add Saccharomyces cerevisiae to the persimmon pulp prepared in step (1), the added amount of Saccharomyces cerevisiae is 18g, and ferment at 23°C for 10 days to obtain a fermentation broth;

[0029] (3) Separate the fermentation broth obtained in step (2) into filtrate and filter residue, put the filtrate into a distillation bottom pot, mix the filter residue and bran to make mash. The addition amount of bran is 8kg, and the wine The fermented glutinous rice is put into a retort bucket, and the fermented fermented glutinous powder is fully filled with a retort bucket; the filtrate and filter residue are distilled at the same time to obtain persimmon wine.

[0030] Persimmon wine obtained in Example 1: 2590g, alcohol content 66 degrees; wine tail: 682g, alcohol content 10.5 de...

Embodiment 2

[0037] A preparation method of persimmon wine includes the following steps:

[0038] (1) Raw material pretreatment: 30kg of persimmons are selected and crushed to obtain persimmon pulp;

[0039] (2) Fermentation: add Saccharomyces cerevisiae to the persimmon pulp prepared in step (1), the added amount of Saccharomyces cerevisiae is 18g, and ferment at 24°C for 8 days to obtain a fermentation broth;

[0040] (3) Separate the fermentation broth obtained in step (2) into filtrate and filter residue, put the filtrate into a distillation bottom pot, mix the filter residue with 5kg bran and 6kg corn flour to make mash, put the mash Into the retort barrel, the wine mash is fully filled with a retort barrel; the filtrate and the filter residue are distilled at the same time to obtain the persimmon wine.

[0041] Persimmon wine obtained in Example 2: 2634g, wine content of 65 degrees; wine tail 634g, wine content of 17 degrees;

[0042] Converting persimmon wine into 50% persimmon wine, yield: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com