Variable diameter travelling type natural gas pipeline detection robot

A technology of natural gas pipelines and robots, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve problems such as impassability, many elbows, and large pipe diameter changes, and achieve stable travel, prevent slipping, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

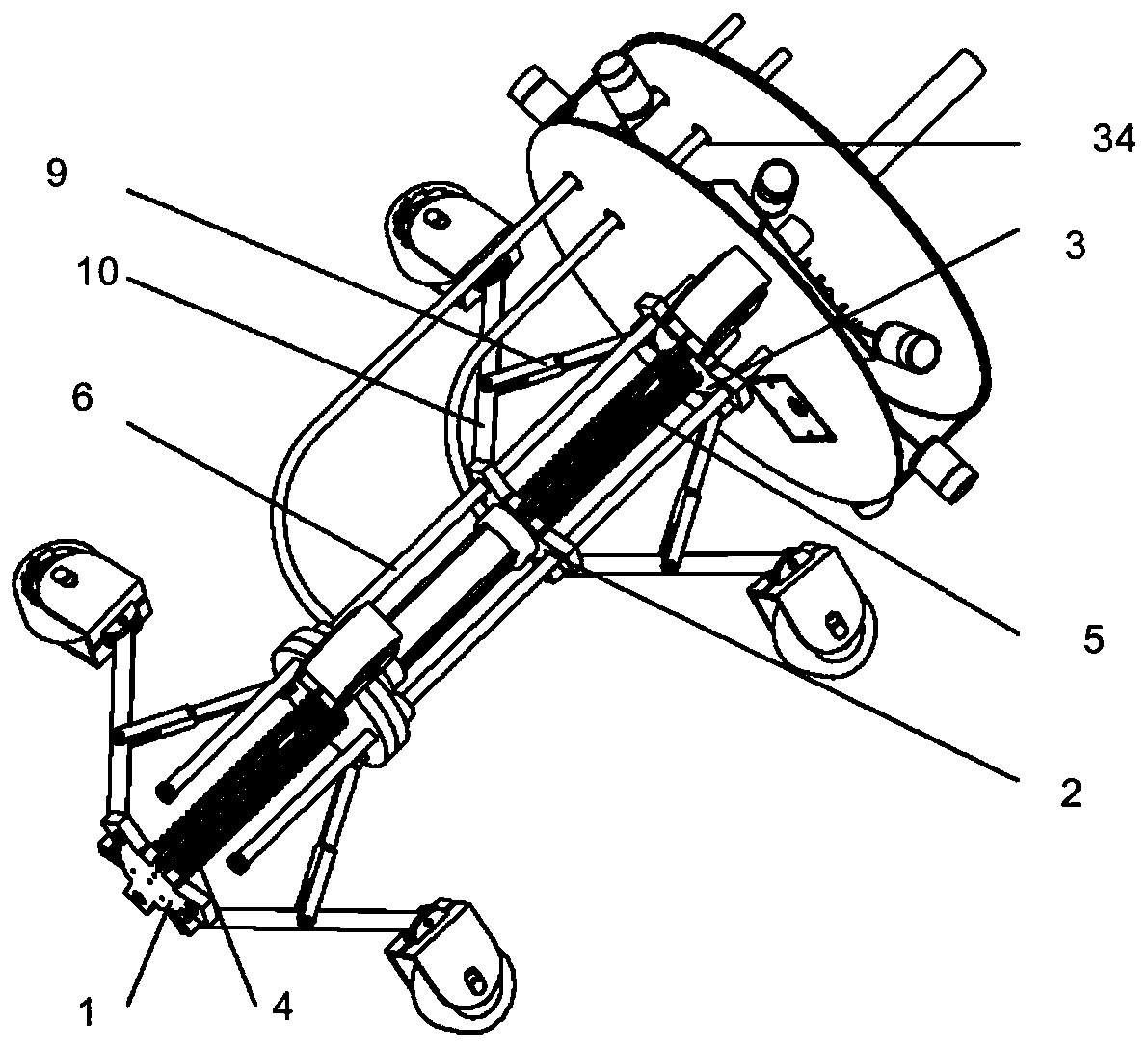

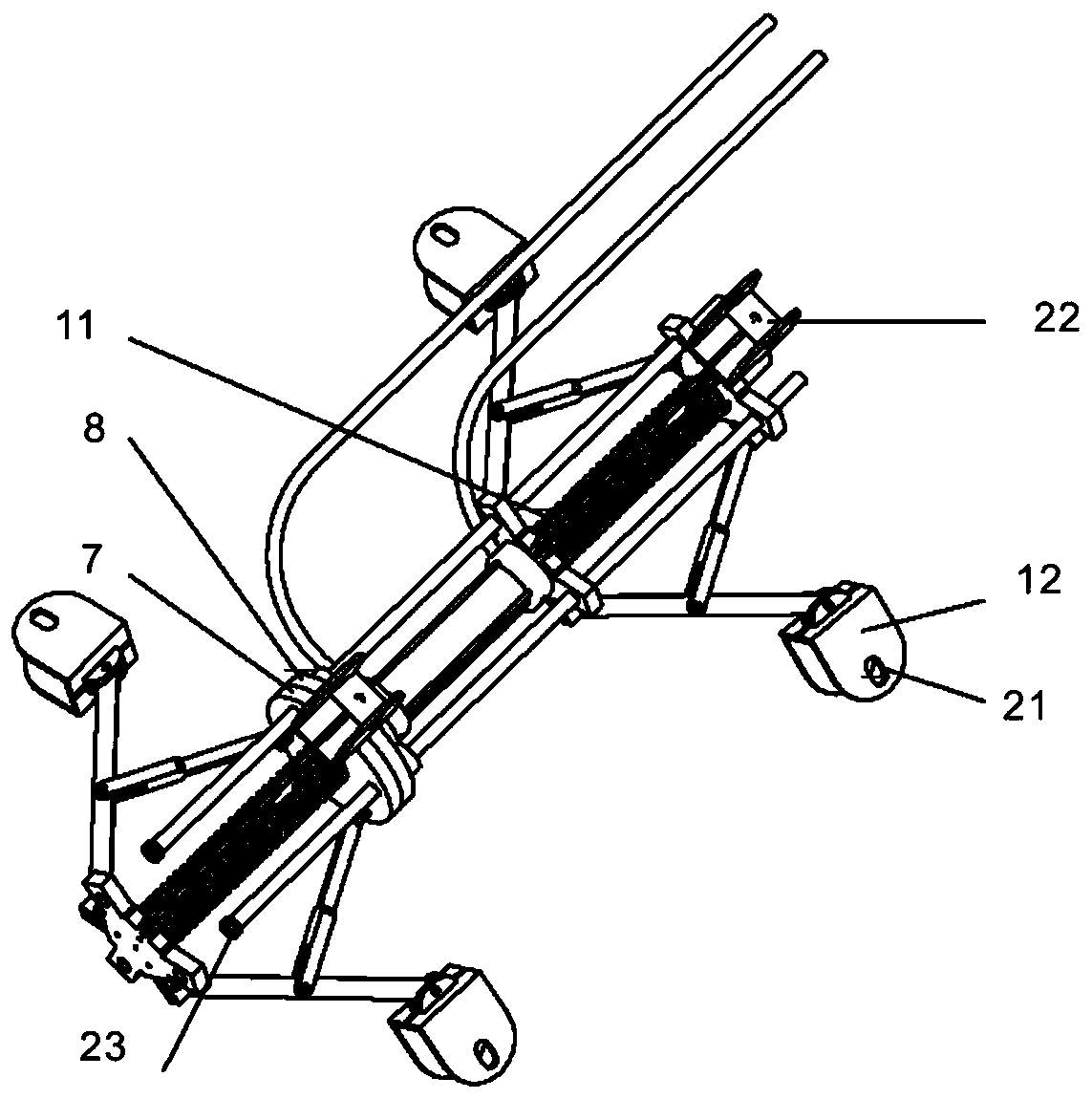

[0027] Embodiment 1. The present invention includes a variable diameter mechanism, a walking mechanism, a hydraulic cylinder and a detection device. A variable diameter mechanism is arranged at both ends of the hydraulic cylinder, and the bottom ends of the two ends of the variable diameter mechanism are connected to a walking mechanism. With detection device;

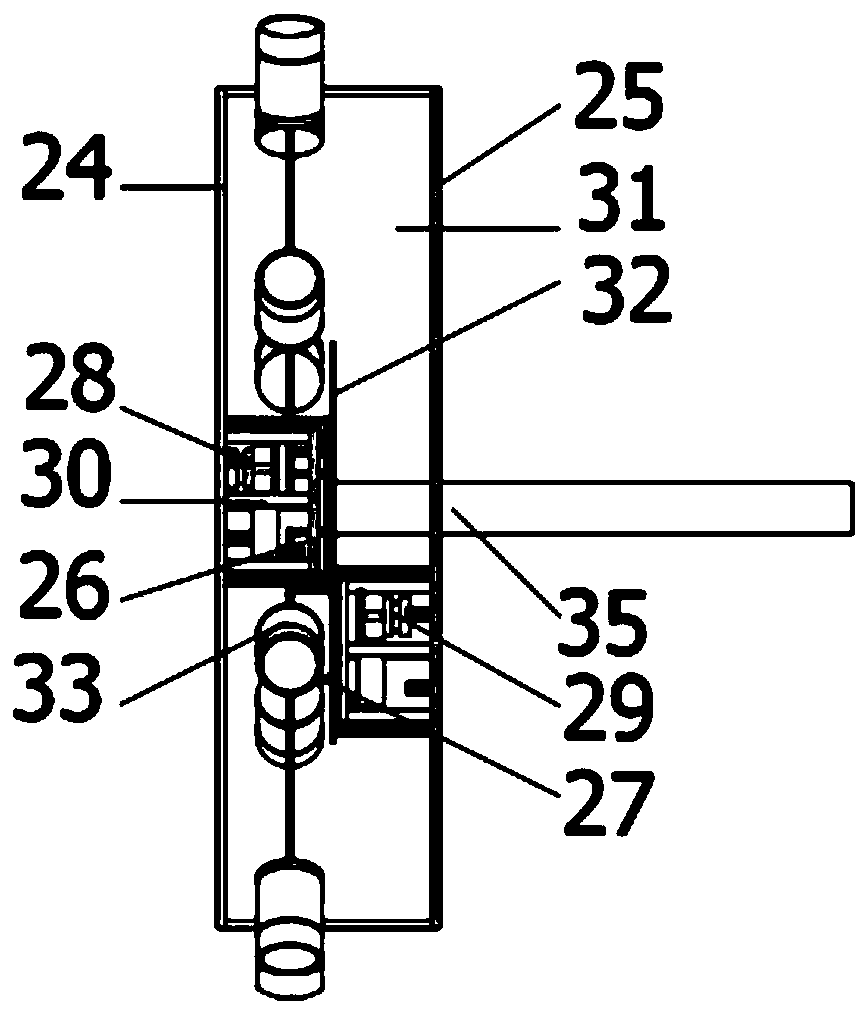

[0028] The reducing mechanism comprises a first spring push rod 4, a second spring push rod 5, a major shaft 6, a synchronous disk 7, a slide block 8, an auxiliary rod 9, a crank 10, a spring 11 and a wheel base 12; A digital camera mounting plate 24 is connected with the long axis 6 that runs through the synchronous disc 7, the slide block 8, the second support plate 2 and the third support plate 3, and the side of the slide block 8 is connected with the synchronous disc 7, and the synchronous disc 7 is connected to the first The support plates 1 are connected by the first spring push rod 4, the rear end of the first ...

Embodiment 2

[0032] Embodiment 2, on the basis of Embodiment 1, the number of auxiliary rods 9, cranks 10, and wheel bases 12 in the variable diameter mechanism at the front and rear ends of the robot is three, and the three wheel bases 12 are distributed at 120°. Within the radial circumference range, it is convenient for the robot to move in the pipeline.

Embodiment 3

[0033] Embodiment 3, on the basis of Embodiment 1, the front end of the long shaft 6 is filled with a rubber washer 25 to prevent rigid collision between the long shaft 6 and the synchronous disc 7 from damaging parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com