Electromagnetic shielding film with high shielding performance and production process thereof

A technology of electromagnetic shielding film and shielding performance, which is applied in the fields of magnetic/electric field shielding, crosstalk/noise/electromagnetic interference reduction (, circuit devices, etc.), and can solve the problem of brittle fracture of the metal layer of the electromagnetic shielding film, increased material and production costs, and grounding Increased resistance and other issues, to achieve outstanding bending resistance, good electromagnetic shielding effectiveness, and prevent charge overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

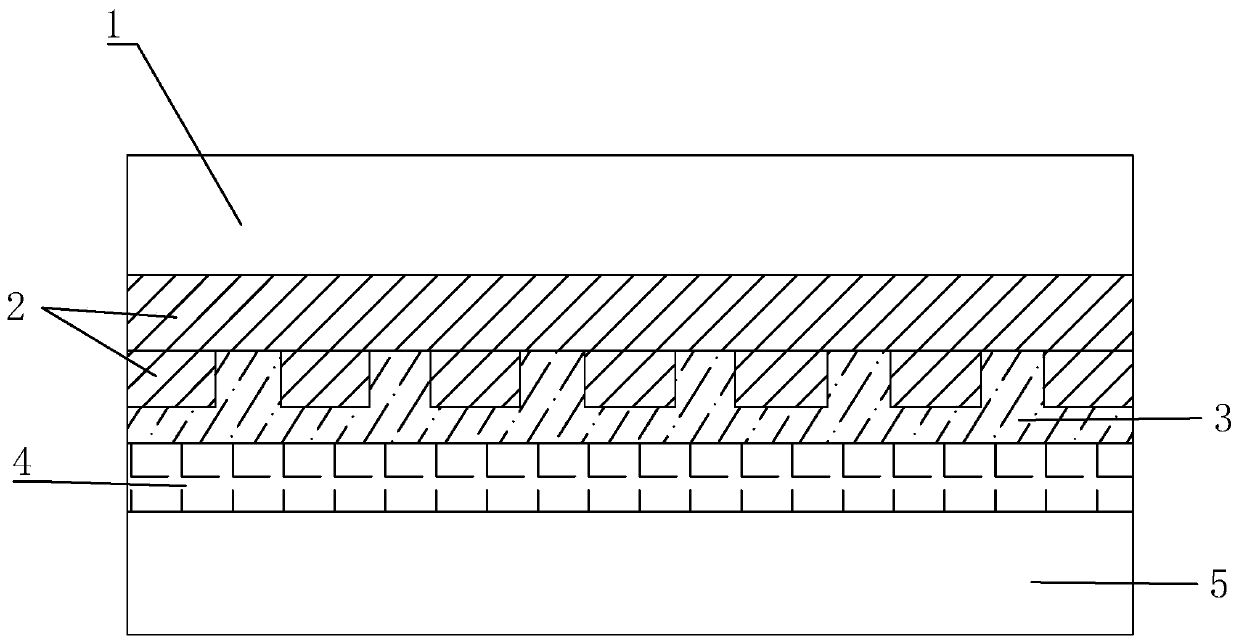

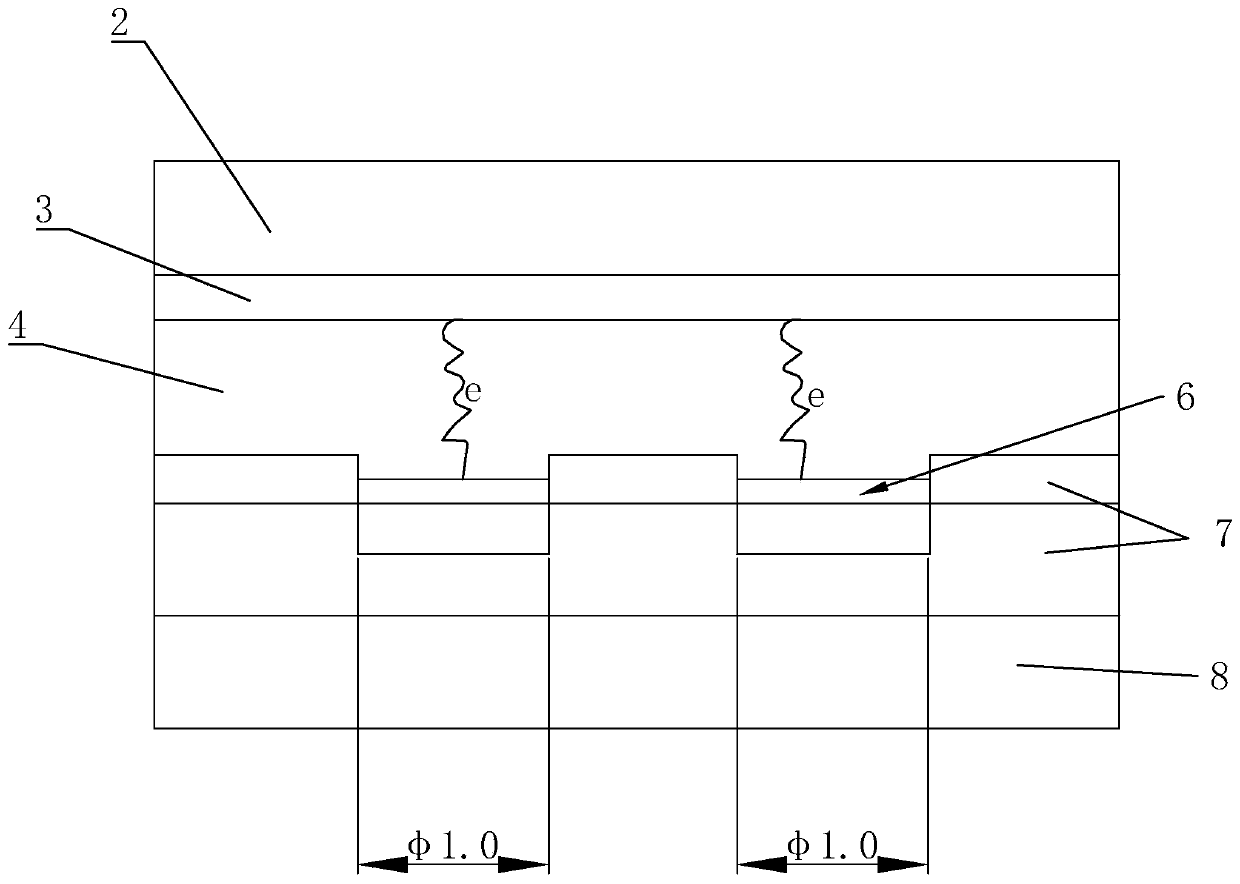

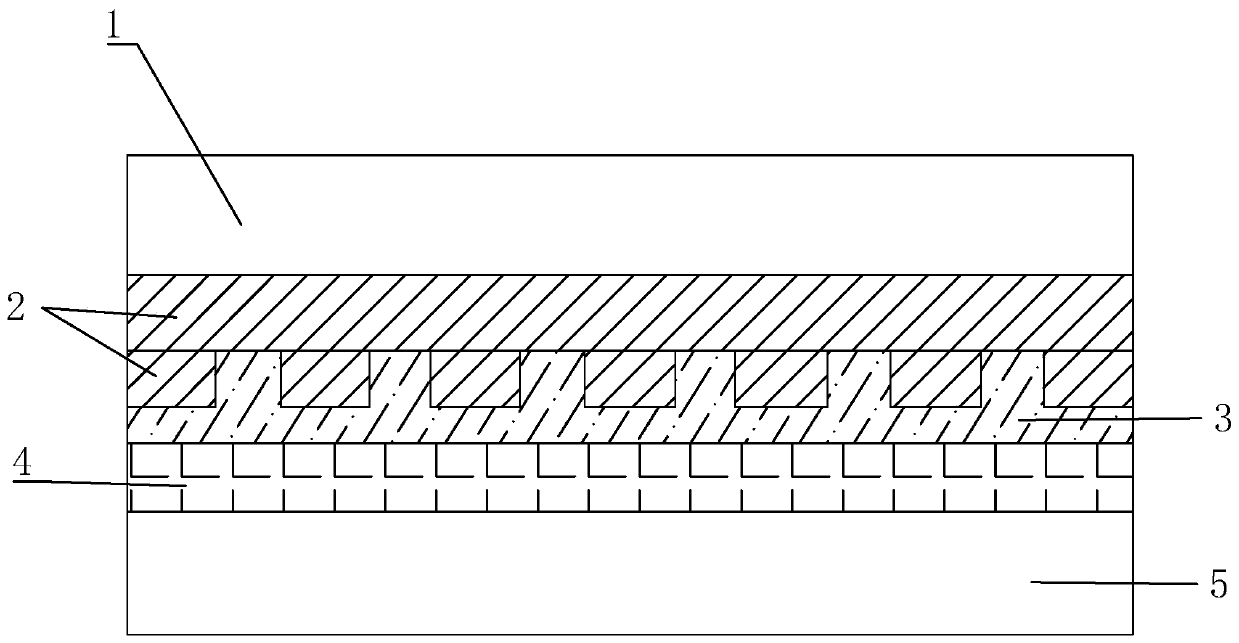

[0055] Such as figure 1 As shown, the electromagnetic shielding film with high shielding performance provided by the present invention has a product structure as follows: a carrier film 1, a grid-like insulating layer 2, a grid-like metal shielding layer 3, a conductive adhesive layer 4, and a protective film 5.

[0056] The carrier film 1 of this embodiment is a non-silicon release film, and its film material can be one of polyester film, polyimide film and the like. Carrier film selects the non-silicon release film main effect of polyester film, polyimide film to be convenient to form insulating layer 2, and the insulating layer in the present embodiment is to be made by resin, and the insulating layer that resin is made can better Attached to the surface of polyester film and polyimide film. In addition, the carrier film can also play a supporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com