Curable granular silicone composition, cured object obtained therefrom, and production method therefor

A silicone composition and hardening technology, applied in the direction of semiconductor/solid-state device parts, electric solid-state devices, semiconductor devices, etc., can solve difficult application, difficult to mold composition, difficult to achieve hardenability/rapid hardening, etc. problems, to achieve the effect of high-efficiency manufacturing, excellent color resistance, excellent workability and hardening characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

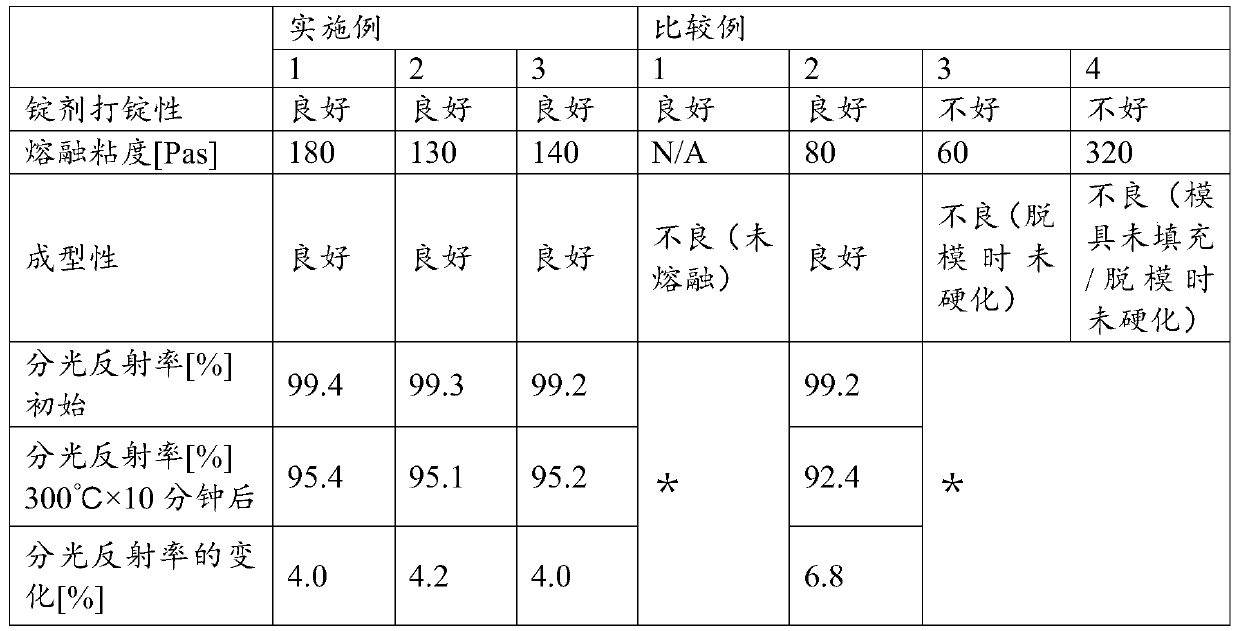

[0144] The curable granular silicone composition of this invention, its manufacturing method, and the processing method of an inorganic filler are demonstrated in detail using an Example and a comparative example. In addition, in the formula, Me, Ph, and Vi represent a methyl group, a phenyl group, and a vinyl group, respectively. Furthermore, with regard to the curable silicone compositions of the respective examples and comparative examples, the pasting properties, melt viscosity, moldability, and spectral reflectance were measured by the following methods. Then, the cured product was produced by heating the curable granular silicone composition at 150°C for 2 hours, and the spectral reflectance, hardness, and bending strength immediately after curing / after the heat resistance test were measured by the following methods. The results are shown in Table 1.

[0145] [Tablet-beating property]

[0146] The tabletability of the tablet was confirmed by compression-molding the cur...

reference example 1

[0155] In a 1L flask, put it in the form of a white solid at 25°C, with an average unit formula:

[0156] (Me 2 ViSiO 1 / 2 ) 0.09 (Me 3 SiO 1 / 2 ) 0.43 (SiO 4 / 2 ) 0.48 (HO 1 / 2 ) 0.03

[0157] 270.5 g of a 55% by mass-xylene solution of the indicated organopolysiloxane resin and 1,3-divinyltetramethyldisiloxane complex of platinum Disiloxane solution (platinum metal content = about 4000ppm) 0.034g, uniformly stirred at room temperature (25°C) to prepare organopolysiloxane resin (1) containing 10ppm platinum metal in xylene solution. Furthermore, this organopolysiloxane resin (1) does not soften / melt even when heated, and does not have thermal fusibility.

reference example 2

[0159] In a 1L flask, put it in the form of a white solid at 25°C, with an average unit formula:

[0160] (Me 2 ViSiO 1 / 2 ) 0.05 (Me 3 SiO 1 / 2 ) 0.39 (SiO 4 / 2 ) 0.56 (HO 1 / 2 ) 0.02

[0161] 270.5 g of a 55% by mass-xylene solution of the indicated organopolysiloxane resin and 1,3-divinyltetramethyldisiloxane complex of platinum Disiloxane solution (platinum metal content = about 4000ppm) 0.034g was uniformly stirred at room temperature (25°C) to prepare organopolysiloxane resin (2) containing 10ppm platinum metal in xylene solution. Furthermore, this organopolysiloxane resin (2) does not soften / melt even when heated, and does not have thermal fusibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com