Insect-resistant PC/ABS alloy material and preparation method thereof

A technology of alloy materials and insect repellent, which is applied in the field of home appliance materials, can solve the problems of physical health, susceptibility to harmful bacteria, etc., and achieve the effects of improving mechanical properties, excellent insect repellent effect, and improved insect repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

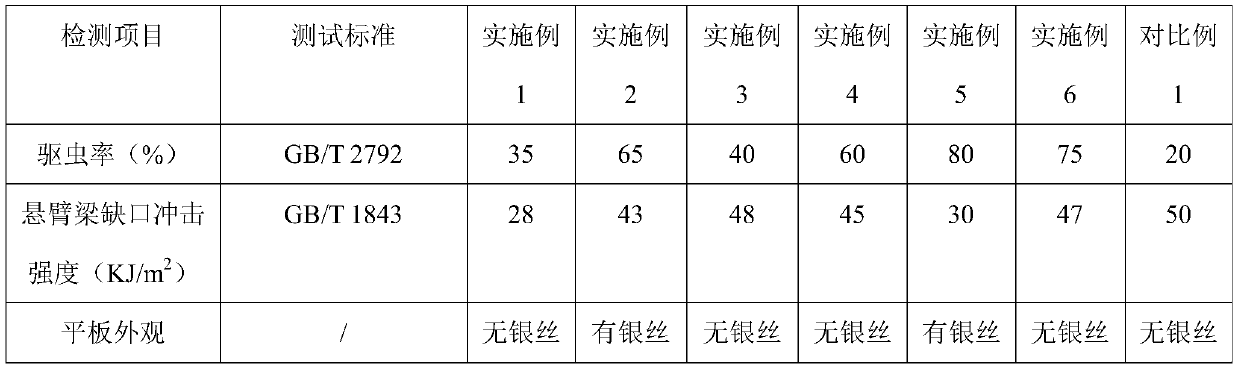

Examples

Embodiment 1

[0017] An insect-proof PC / ABS alloy material, comprising the following raw materials in parts by weight:

[0018] 50 parts of polycarbonate, 50 parts of acrylonitrile-butadiene-styrene copolymer, 1 part of berberine, 0.1 part of antioxidant, and 0.1 part of lubricant.

[0019] Among them, the polycarbonate has a melt index of 22g / 10min under the conditions of 300°C and 1.2kg; the antioxidant is a mixture of phenolic antioxidant and phosphite antioxidant.

[0020] The preparation method of insect-proof PC / ABS alloy material comprises the following steps: taking raw materials by weight, polycarbonate, acrylonitrile-butadiene-styrene copolymer, methyl methacrylate-butadiene-styrene copolymer Compound, berberine, antioxidant, and lubricant are melted, extruded and granulated through a twin-screw extruder; the heating temperature of the screw barrel of the twin-screw extruder from zone 1 to zone 9 is as follows: 180°C, 250°C °C, 250 °C, 250 °C, 250 °C, 240 °C, 240 °C, 230 °C, 210 ...

Embodiment 2

[0022] An insect-proof PC / ABS alloy material, comprising the following raw materials in parts by weight:

[0023] 80 parts of polycarbonate, 10 parts of acrylonitrile-butadiene-styrene copolymer, 5 parts of methyl methacrylate-butadiene-styrene copolymer, 3 parts of berberine, 0.5 parts of antioxidant, lubricant 0.6 parts.

[0024] Among them, the polycarbonate has a melt index of 22g / 10min under the conditions of 300°C and 1.2kg; the antioxidant is a mixture of phenolic antioxidant and phosphite antioxidant.

[0025] The preparation method of insect-proof PC / ABS alloy material comprises the following steps: taking raw materials by weight, polycarbonate, acrylonitrile-butadiene-styrene copolymer, methyl methacrylate-butadiene-styrene copolymer Compound, berberine, antioxidant, and lubricant are melted, extruded and granulated through a twin-screw extruder; the heating temperature of the screw barrel of the twin-screw extruder from zone 1 to zone 9 is as follows: 180°C, 250°C ...

Embodiment 3

[0027] An insect-proof PC / ABS alloy material, comprising the following raw materials in parts by weight:

[0028] 70 parts of polycarbonate, 27 parts of acrylonitrile-butadiene-styrene copolymer, 2 parts of methyl methacrylate-butadiene-styrene copolymer, 1 part of berberine, 0.2 parts of antioxidant, lubricant 0.2 parts.

[0029] Among them, the polycarbonate has a melt index of 22g / 10min under the conditions of 300°C and 1.2kg; the antioxidant is a mixture of phenolic antioxidant and phosphite antioxidant.

[0030] The preparation method of insect-proof PC / ABS alloy material comprises the following steps: taking raw materials by weight, polycarbonate, acrylonitrile-butadiene-styrene copolymer, methyl methacrylate-butadiene-styrene copolymer Compound, berberine, antioxidant, and lubricant are melted, extruded and granulated through a twin-screw extruder; the heating temperature of the screw barrel of the twin-screw extruder from zone 1 to zone 9 is as follows: 180°C, 250°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com