Preparation process and application of slurry for high-efficiency drilling of steep and sparse clastic rock stratum

A clastic rock and mud technology, which is applied in the high-efficiency drilling mud preparation process and application field of steep and dry clastic rock formations, can solve the problems of scrapped drilling, shrinking of borehole diameter, and easy disturbance of gravel, etc., and achieve safe and fast drilling. The effect of drilling and preventing flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

[0056] The present invention provides a mud preparation process and application suitable for the drilling needs of steep dry clastic rock formations. Taking 400m as the boundary, two different mud systems suitable for less than 400m and more than 400m have been developed, which are used to reduce up to 400m Eliminate common engineering technical problems such as block dropping, leakage, diameter shrinkage and hole collapse, and ensure efficient construction.

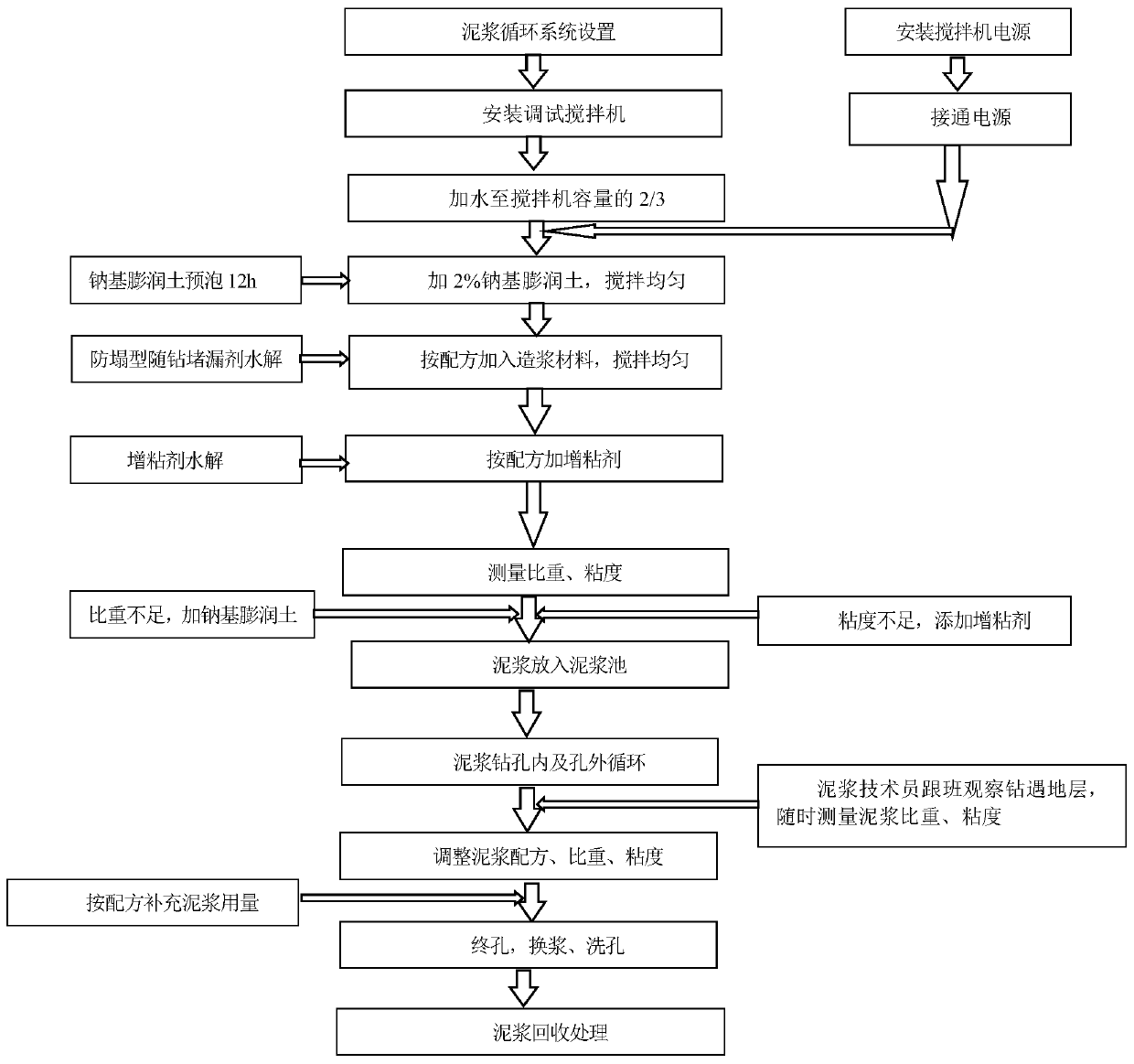

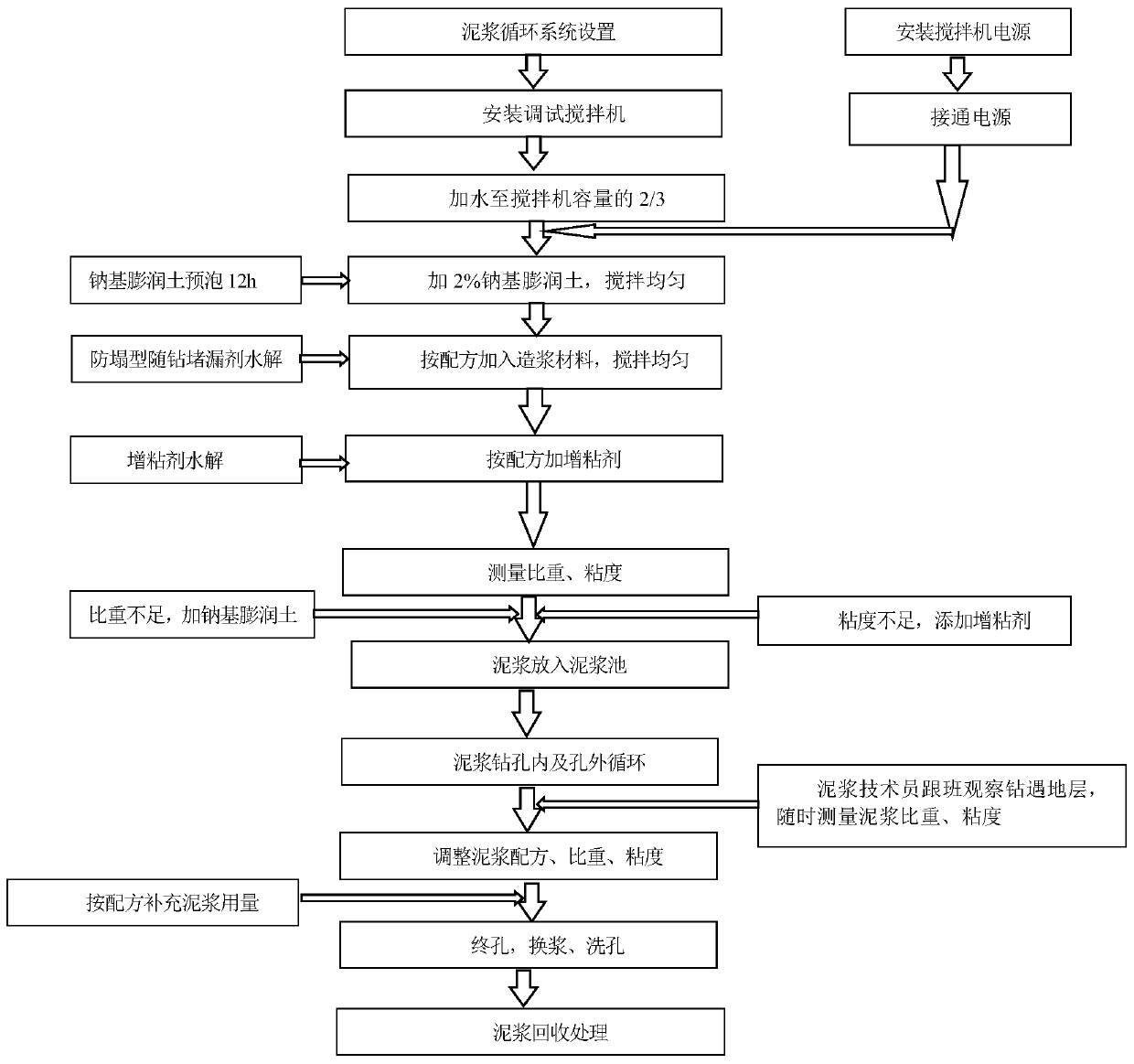

[0057] figure 1 A flow chart of the mud preparation process provided by the present invention. Specific steps are as follows:

[0058] (1) The first step is the setting, installation and commissioning of the mud circulation system. The installation principles are safety, stability and operability.

[0059] (2) In the second step, add clear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com