Technology of beta vulgaris fermented wine

A technology for fermenting wine and sugar beet, applied in the field of winemaking, can solve problems such as reducing the green flavor of vegetable roots, achieve the effects of pure aroma, ensure quality and efficiency, and improve color and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

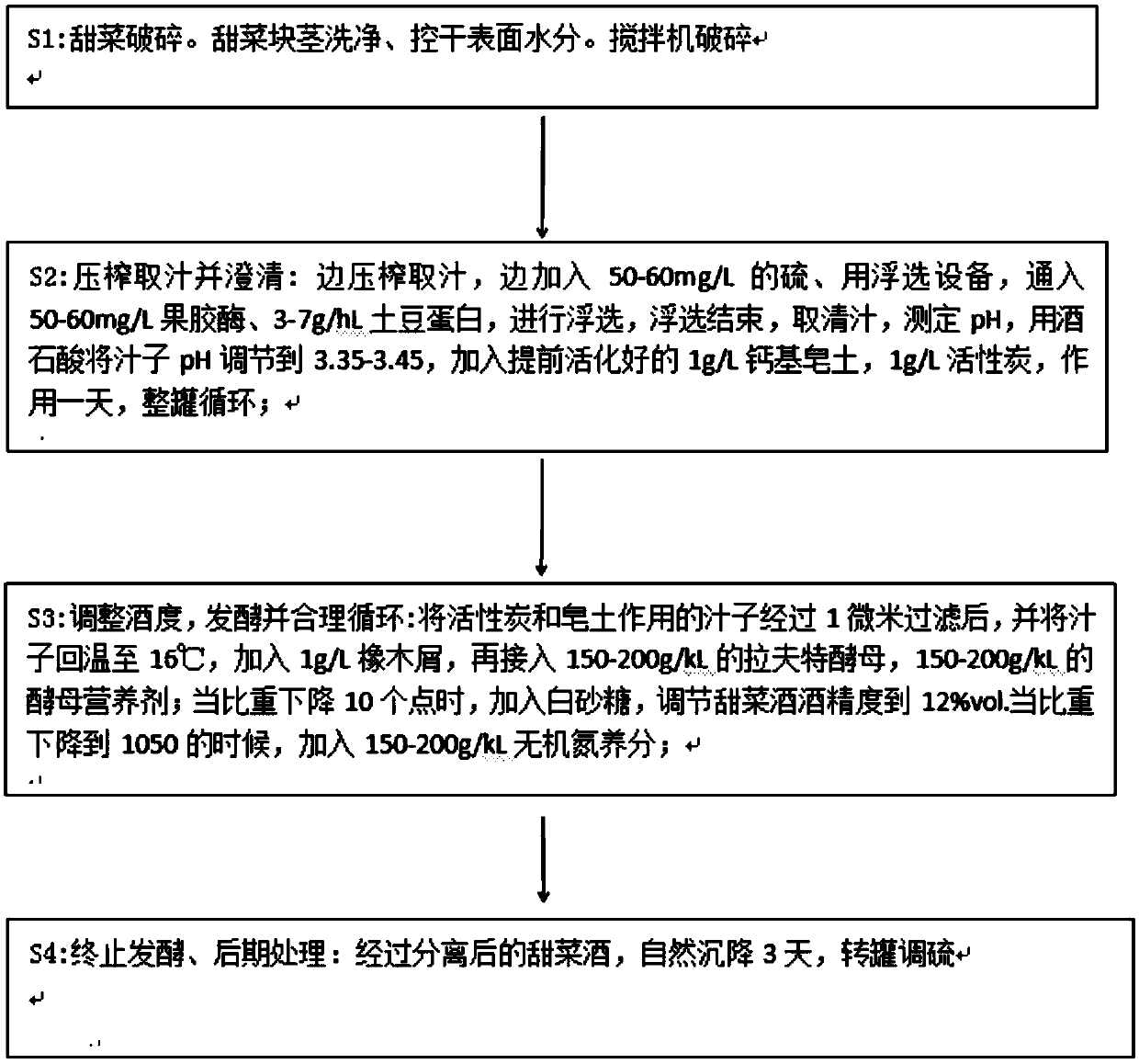

[0028] A sugar beet fermented wine process, comprising the steps of:

[0029] 1) Wash the beet tubers, air-dry the surface moisture, crush them with a mixer, and extract the juice;

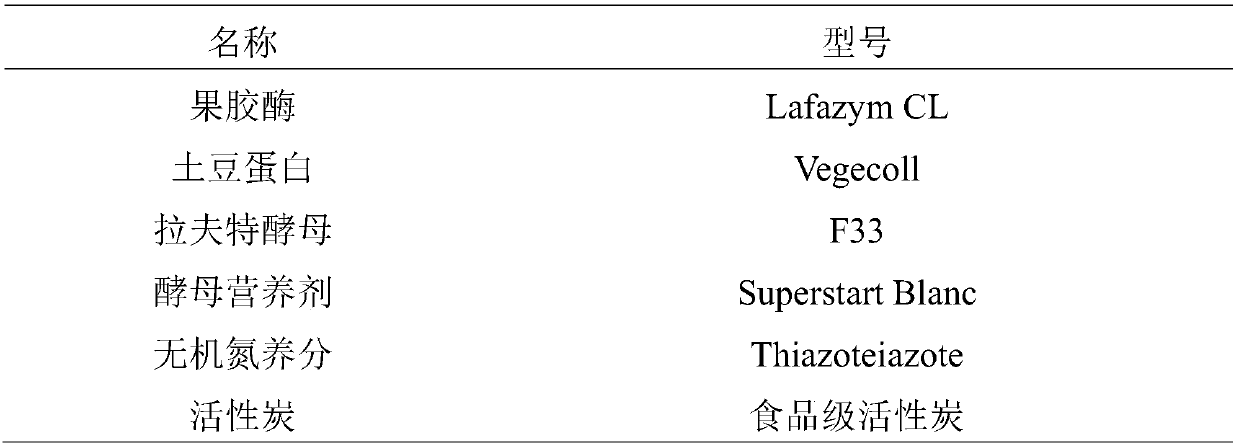

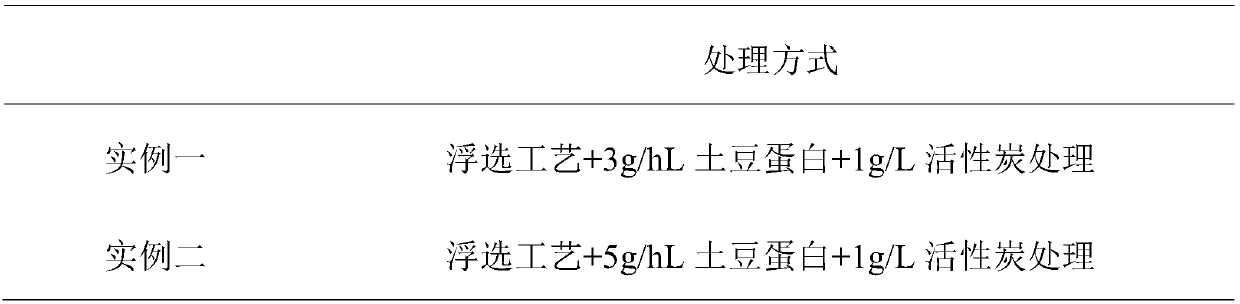

[0030] 2) Squeeze the juice and clarify: squeeze the juice, add 50mg / L sulfur, use flotation equipment, pass 50mg / L pectinase, 3g / hL potato protein, and carry out flotation. Clean the juice, measure the pH, adjust the pH of the juice to 3.4 with tartaric acid, add 1g / L calcium-based bentonite activated in advance, 1g / L activated carbon, act for one day, and circulate the whole tank;

[0031] 3) Adjust the alcohol content, ferment and circulate reasonably: filter the juice with activated carbon and bentonite at 1 micron, return the juice to 16°C, add 1g / L oak chips, and then add 200g / kL Rafter yeast, 150-200g / kL yeast nutrient; when the specific gravity drops by 10 points, add white sugar, adjust the alcohol content of beet wine to 12% vol. When the specific gravity drops to 1050, add 200g / kL inor...

Embodiment 2

[0034] A sugar beet fermented wine process, comprising the steps of:

[0035] 1) Wash the beet tubers, air-dry the surface moisture, crush them with a mixer, and extract the juice;

[0036] 2) Squeeze the juice and clarify: squeeze the juice, add 60mg / L sulfur, use flotation equipment, pass 60mg / L pectinase, 5g / hL potato protein, and carry out flotation. After flotation, take Clean the juice, measure the pH, adjust the pH of the juice to 3.35-3.45 with tartaric acid, add 1g / L calcium-based bentonite activated in advance, 1g / L activated carbon, act for one day, and circulate the whole tank;

[0037] 3) Adjust the alcohol content, ferment and circulate reasonably: filter the juice with activated carbon and bentonite at 1 micron, return the juice to 16°C, add 1g / L oak chips, and then add 200g / kL Rafter yeast, 200g / kL yeast nutrient; when the specific gravity drops by 10 points, add white sugar, adjust the alcohol content of beet wine to 12% vol. When the specific gravity drops t...

Embodiment 3

[0040] A sugar beet fermented wine process, comprising the steps of:

[0041] 1) Wash the beet tubers, air-dry the surface moisture, crush them with a mixer, and extract the juice;

[0042] 2) Squeeze the juice and clarify: squeeze the juice, add 60mg / L sulfur, use flotation equipment, pass 60mg / L pectinase, 7g / hL potato protein, and carry out flotation. Clean the juice, measure the pH, adjust the pH of the juice to 3.4 with tartaric acid, add 1g / L calcium-based bentonite activated in advance, 1g / L activated carbon, act for one day, and circulate the whole tank;

[0043] 3) Adjust the alcohol content, ferment and circulate reasonably: filter the juice with activated carbon and bentonite at 1 micron, return the juice to 16°C, add 1g / L oak chips, and then add 200g / kL Rafter yeast, 150-200g / kL yeast nutrient; when the specific gravity drops by 10 points, add white sugar, adjust the alcohol content of beet wine to 12% vol. When the specific gravity drops to 1050, add 200g / kL inorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com