Plant foliar fertilizer, preparation method and application thereof

A foliar fertilizer and plant technology, which is applied in the field of plant foliar fertilizer and its preparation, can solve the problems of decreased plant absorption rate, poor plant resistance, and excessive use of pesticides, and achieves increased plant absorption rate, activation activity, and no soil The effect of hardening risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

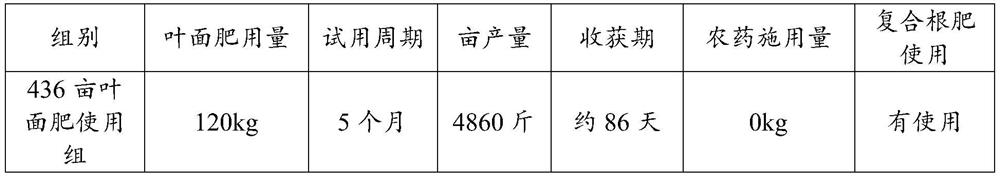

Examples

preparation example Construction

[0030] The invention provides a preparation method of plant foliage fertilizer, which comprises the following steps: 1) crushing animal source raw materials and mixing them with water, heating and slaking to obtain a slaking feed liquid; 2) mixing the slaking feed liquid with a compound biological preparation Perform a biochemical reaction to obtain a biochemical degradation solution; the temperature of the biochemical reaction is 50-60°C, and the time of the biochemical reaction is preferably 50-70 minutes; 3) inactivate and filter the composite biological agent in the biochemical degradation solution, Collect the filtrate; 4) Mix the filtrate with water and a pH regulator to obtain a plant foliar fertilizer; the solid soluble content of the plant foliage fertilizer is ≥ 2%, and the pH value is 6.0 to 9.0; the compound biological preparation The composition includes the following components by weight: 2-5 parts of gastric digestive protease, 15-18 parts of trypsin, 27.5-33 par...

Embodiment 1

[0040] 1. Raw materials: 50kg of fish sausages slaughtered from fishery processing plants;

[0041] 2. Pretreatment: After the raw fish intestines are frozen, they are physically crushed and crushed to 60 mesh;

[0042] 3. Primary hydrolysis: Add 5 times the amount of water to the crushed raw materials, continue to stir, heat the materials to 92°C, and cook at a constant temperature for 1 hour;

[0043] 4. Biochemical degradation: reduce the temperature of the material and control it at 53°C, add 0.02% to 0.65% of compound biological preparations, keep stirring, and continue the biochemical reaction for 1 hour;

[0044] 5. Inactivation: After the biochemical reaction is over, raise the temperature of the material to 82°C and keep it for 10 minutes;

[0045] 6. Filtration: Use a bag filter or plate and frame filter to filter out the residue through the filter cloth, and the filtrate enters the next process;

[0046] 7. Deployment: the material filtrate is measured by solid so...

Embodiment 2

[0049] 1. Raw materials: 100kg of fish intestines and some dead fish and shrimps from supermarket slaughtering residue;

[0050] 2. Pretreatment: physical crushing of animal source materials to 60 mesh;

[0051] 3. Primary hydrolysis: Add 5 times of water to the crushed raw materials, continue to stir, heat the materials to above 90°C, and cook at constant temperature for 1 hour;

[0052] 4. Biochemical degradation: reduce the material temperature and control it at 57°C, add 0.3% of the compound biological agent, keep stirring, and continue the biochemical reaction for 1 hour;

[0053] 5. Inactivation: After the biochemical reaction is over, raise the temperature of the material to 80°C and keep it for 10 minutes;

[0054] 6. Filtration: Use a bag filter or plate and frame filter to filter out the residue through the filter cloth, and the filtrate enters the next process;

[0055] 7. Deployment: The material filtrate is measured by solid soluble content, and according to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com