Green preparation method of functional protein powder and product

A protein powder, functional technology, applied in animal protein processing and other directions, can solve the problems of inability to match the environmental conditions of meat products, damage to the triple helix structure of collagen molecules, weak gelling and emulsification, etc. The effect of low equipment requirements and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

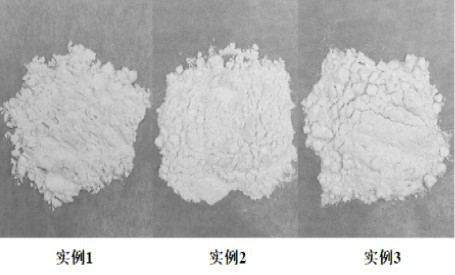

Embodiment 1

[0029] Prepare functional protein powder.

[0030] (1) Pretreatment: using pigskin as raw material, the pigskin is preliminarily cleaned with water, and the fat layer of the pigskin is scraped off;

[0031] (2) Short-term precooking: precook the pigskin with boiling water for 5 minutes, remove and scrape off the grease layer, rinse twice with 45°C warm water, remove and put into 15°C water, and drain;

[0032] (3) Grinding: Grinding the pigskin treated in step (2) with a meat grinder to obtain pigskin pieces with a size of 2-5 mm × 2-5 mm;

[0033] (4) Degreasing: add 0.06% sucrose fatty acid ester solution to the pigskin pieces treated in step (3) at a solid-liquid ratio (w:v) of 1:2.5, ultrasonic degreasing time is 20 min, and the temperature is 60°C , the power is 120 W, and the degreasing fluid is replaced every 10 min;

[0034] (5) Wash and drain: wash the pigskin pieces treated in step (4) with water and drain;

[0035] (6) Drying: put the pigskin block treated in ste...

Embodiment 2

[0038] Prepare functional protein powder.

[0039] (1) Pretreatment: using pigskin as raw material, the pigskin is preliminarily cleaned with water, and the fat layer of the pigskin is scraped off;

[0040] (2) Short-term precooking: precook the pigskin with boiling water for 5 minutes, remove and scrape off the grease layer, rinse twice with 45°C warm water, remove and put into 15°C water, and drain;

[0041] (3) Grinding: Grinding the pigskin treated in step (2) with a meat grinder to obtain pigskin pieces with a size of 2-5 mm × 2-5 mm;

[0042] (4) Degreasing: add 0.06% sucrose fatty acid ester solution to the pigskin pieces treated in step (3) at a solid-liquid ratio (w:v) of 1:2.5, ultrasonic degreasing time is 20 min, and the temperature is 60°C , the power is 120 W, and the degreasing fluid is replaced every 10 min;

[0043] (5) Wash and drain: wash the pigskin pieces treated in step (4) with water and drain;

[0044](6) Drying: put the pigskin block treated in step...

Embodiment 3

[0047] Prepare functional protein powder.

[0048] (1) Pretreatment: using pigskin as raw material, the pigskin is preliminarily cleaned with water, and the fat layer of the pigskin is scraped off;

[0049] (2) Short-term precooking: precook the pigskin with boiling water for 5 minutes, remove and scrape off the grease layer, rinse twice with 45°C warm water, remove and put into 15°C water, and drain;

[0050] (3) Grinding: Grinding the pigskin treated in step (2) with a meat grinder to obtain pigskin pieces with a size of 2-5 mm × 2-5 mm;

[0051] (4) Degreasing: add 0.06% sucrose fatty acid ester solution to the pigskin pieces treated in step (3) at a solid-liquid ratio (w:v) of 1:2.5, ultrasonic degreasing time is 20 min, and the temperature is 60°C , the power is 120 W, and the degreasing fluid is replaced every 10 min;

[0052] (5) Wash and drain: wash the pigskin pieces treated in step (4) with water and drain;

[0053] (6) Drying: put the pigskin block treated in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com