Preparation process of photocatalyst

A photocatalyst and preparation process technology, applied in physical/chemical process catalysts, biocides, disinfectants, etc., can solve the problems of long natural cooling process, long preparation process time, affecting preparation efficiency, etc., to reduce the cost of raw materials, improve Preparation speed and efficiency, the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

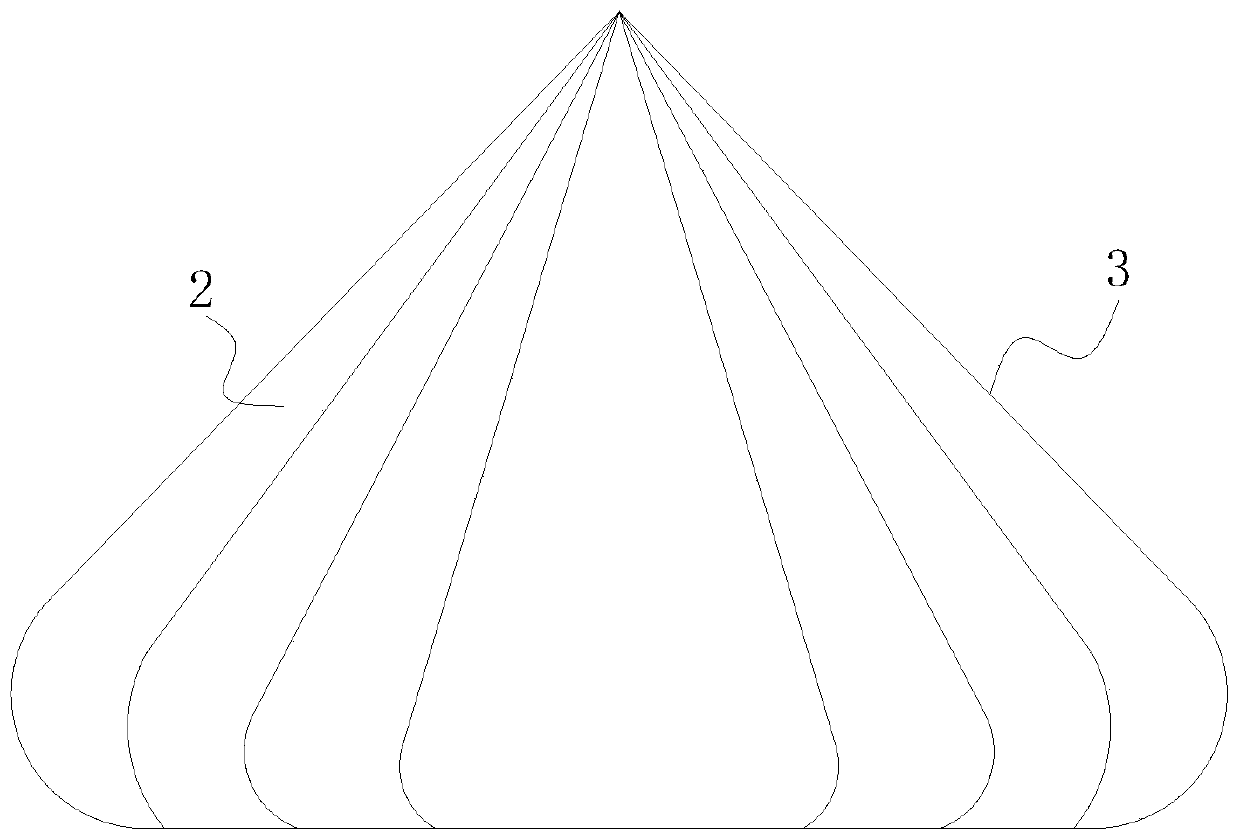

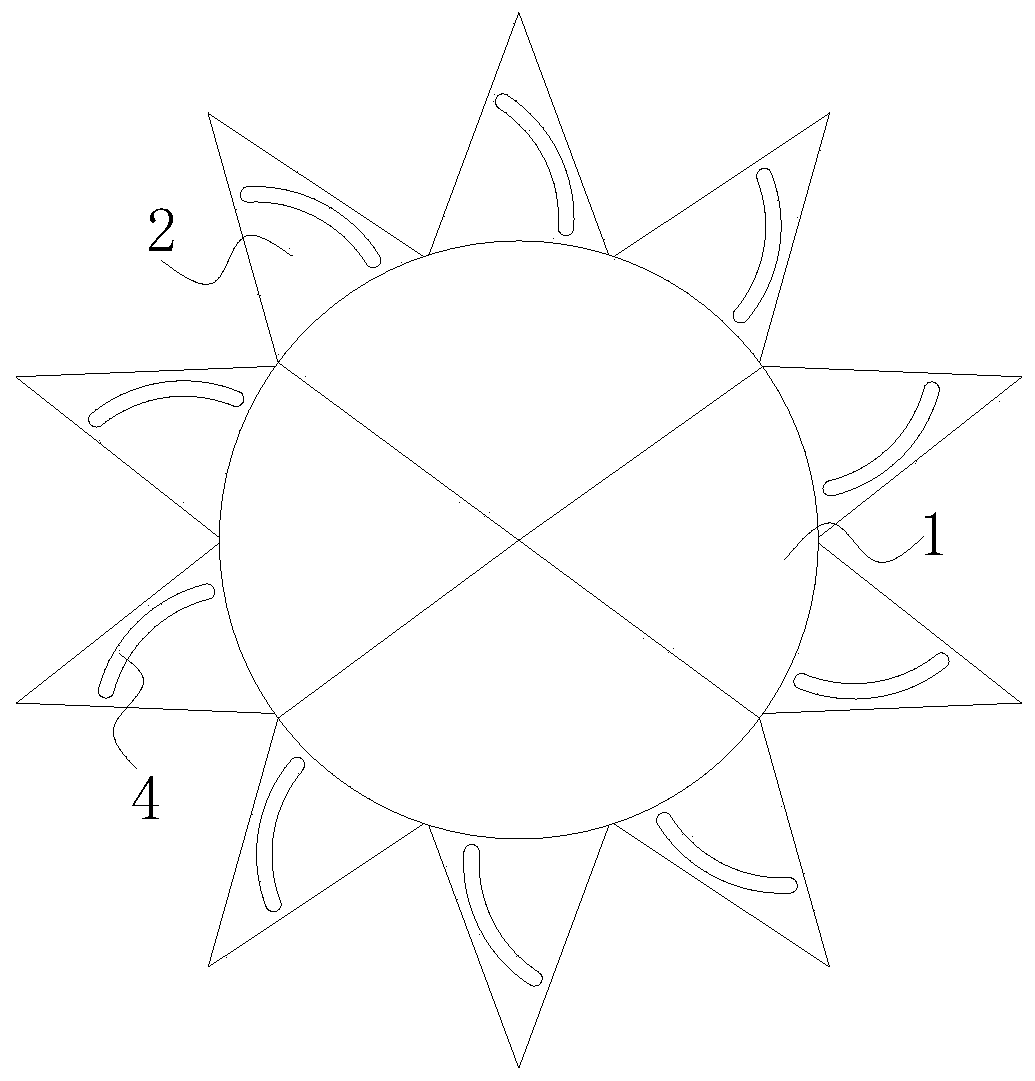

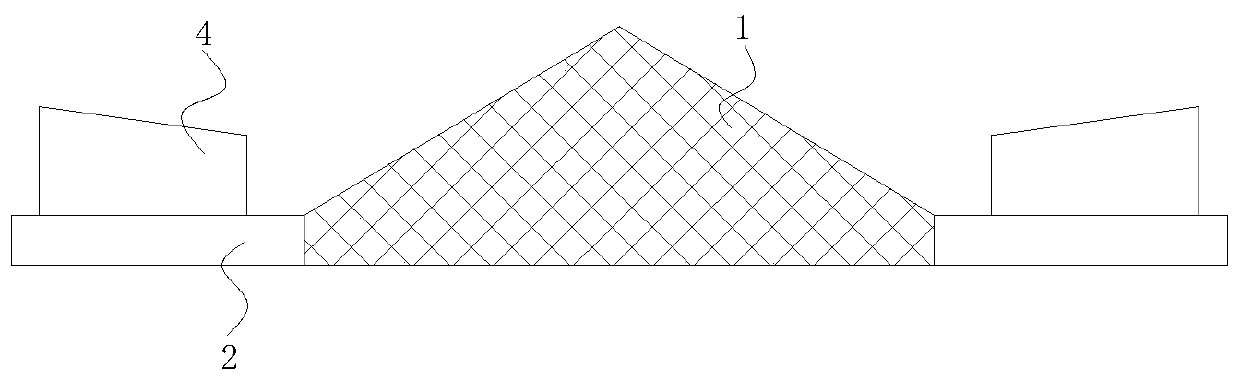

[0028] use Figure 1-Figure 4 The preparation process of a photocatalyst according to an embodiment of the present invention is described as follows.

[0029] like Figure 1-Figure 4 Shown, the preparation technology of a kind of photocatalyst of the present invention, this technology comprises the following steps:

[0030] S1: Put metal titanium into a glass beaker, add aqueous hydrogen peroxide solution to form a mixed solution, the molar ratio of metal titanium to hydrogen peroxide is 1:7; the metal titanium is granular sponge titanium; then place the glass beaker on ice In the water bath, the temperature of the ice-water bath is controlled at 20°C, and the mixed solution is stirred at a medium speed to form an intermediate reactant;

[0031] S2: Pour a certain amount of ammonia water into a flask with a branch pipe and a piston, place the flask in a hot water bath, control the temperature of the water bath at about 60°C, and heat to volatilize ammonia to form ammonia vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com