Composite strain biological fluid bed membrane method and anaerobic filler preparation method

A compound strain, fluidized bed technology, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., to achieve the effect of promoting rapid establishment, releasing inhibition, and promoting step-by-step diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

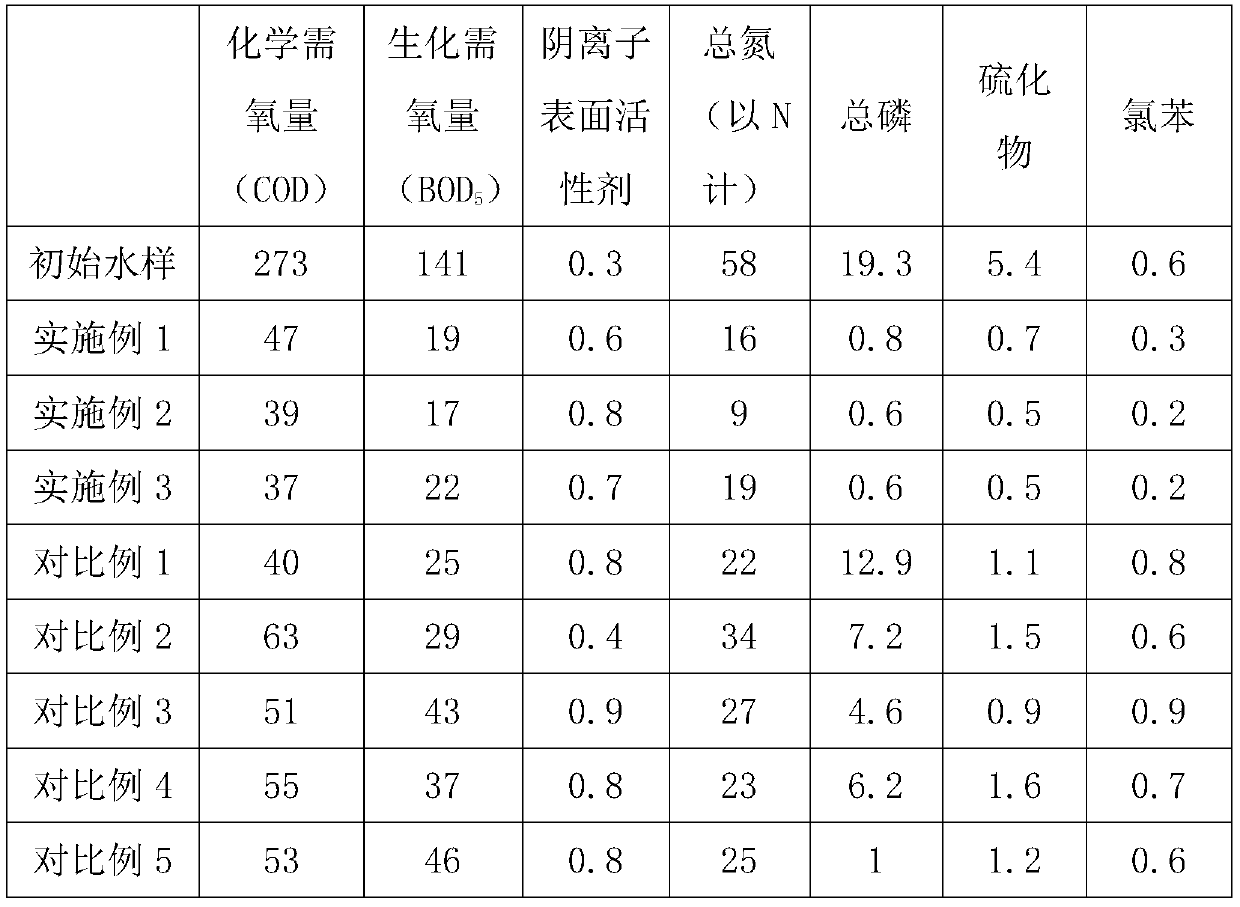

Embodiment 1

[0044] The present invention provides a biofluidized bed membrane method for composite strains. The biofluidized bed membrane method for composite strains includes the following steps: anaerobic tank treatment, anaerobic filler is arranged in the anaerobic tank, and the anaerobic 5% of the water mass in the filled anaerobic tank enters the anaerobic tank for treatment, and the treatment time is 24 hours; for the treatment in the first sedimentation tank, the sewage enters the first sedimentation tank for sedimentation treatment for 6 hours; for the treatment in the aerobic tank, the The aerobic tank is provided with aerobic filler, and the aerobic filler accounts for 5% of the water quality in the anaerobic tank, and the sewage enters the aerobic tank for treatment, and the treatment time is 12 hours; for the second sedimentation tank, the sewage enters Sediment in the second sedimentation tank for 6 hours.

[0045] The anaerobic filler includes a coated net, a middle material...

Embodiment 2

[0050] The present invention provides a biofluidized bed membrane method for composite strains. The biofluidized bed membrane method for composite strains includes the following steps: anaerobic tank treatment, anaerobic filler is arranged in the anaerobic tank, and the anaerobic 20% of the water quality in the filled anaerobic tank enters the anaerobic tank for treatment, and the treatment time is 14 hours; for the treatment in the first sedimentation tank, the sewage enters the first sedimentation tank for sedimentation treatment for 3 hours; for the treatment in the aerobic tank, the The aerobic tank is provided with aerobic filler, and the aerobic filler accounts for 20% of the water quality in the anaerobic tank, and the sewage enters the aerobic tank for treatment, and the treatment time is 7 hours; for the second sedimentation tank, the sewage enters Sediment in the second sedimentation tank for 3 hours.

[0051] The anaerobic filler includes a coated net, a middle mate...

Embodiment 3

[0056] The present invention provides a biofluidized bed membrane method for composite strains. The biofluidized bed membrane method for composite strains includes the following steps: anaerobic tank treatment, anaerobic filler is arranged in the anaerobic tank, and the anaerobic 30% of the water quality in the filled anaerobic tank enters the anaerobic tank for treatment, and the treatment time is 4 hours; for the treatment in the first sedimentation tank, the sewage enters the first sedimentation tank for sedimentation treatment for 1 hour; for the treatment in the aerobic tank, the The aerobic tank is provided with aerobic filler, and the aerobic filler accounts for 30% of the water quality in the anaerobic tank, and the sewage enters the aerobic tank for treatment, and the treatment time is 2 hours; for the second sedimentation tank, the sewage enters Sediment in the second sedimentation tank for 1 hour.

[0057] The anaerobic filler includes a coated net, a middle materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com