Self-filling concrete for railway tunnel lining

A concrete and self-filling technology, which is applied in the field of railway tunnel lining structures and self-filling concrete, can solve problems such as insufficient durability and lining quality defects, and achieve the effects of improving robustness, reducing cracking risks, and reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: The design strength of the tunnel lining self-filling concrete is C30. The concrete mix ratio used is shown in Table 1. The main properties of the tunnel lining self-filling concrete measured in the laboratory are shown in Table 2. The field application and later inspection of the tunnel lining self-filling concrete The situation is shown in Table 3.

[0034] gelling component Viscosity Adjusting Components aggregate water reducing component mixing water 360 1.5 1877 4.0 150

[0035] project Slump spread Vibration spread Gas content Vibration U-shaped instrument filling height difference Penetration depth Initial setting time final setting time 56d compressive strength 28d electric flux performance 530mm 580m 2.5% 40mm 5mm 8:50 10:45 38.5 MPa 940C

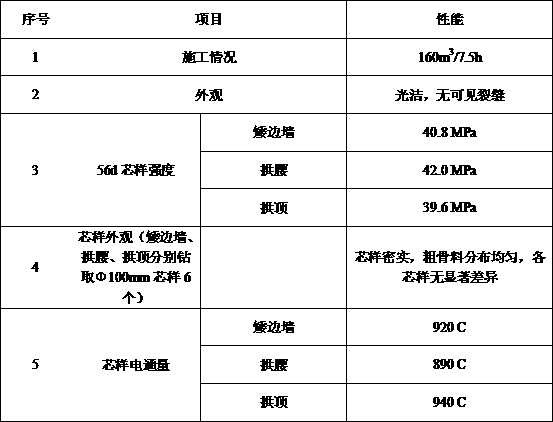

[0036] Table 3 On-site application and later detection of self-filling concrete for C30 tunnel lining

[0037]

Embodiment 2

[0038] Example 2: The design strength of the tunnel lining self-filling concrete is C40. The concrete mix ratio used is shown in Table 4. The main properties of the tunnel lining self-filling concrete measured in the laboratory are shown in Table 5. The field application and later inspection of the tunnel lining self-filling concrete The situation is shown in Table 6.

[0039] gelling component Viscosity Adjusting Components aggregate water reducing component mixing water 450 1.0 1796 4.5 156

[0040] project Slump spread Vibration spread Gas content Vibration U-shaped instrument filling height difference Penetration depth Initial setting time final setting time 56d compressive strength Impermeability grade 28d electric flux performance 520mm 580m 3.1% 30mm 4mm 9:10 11:10 50.7 MPa P12 820C

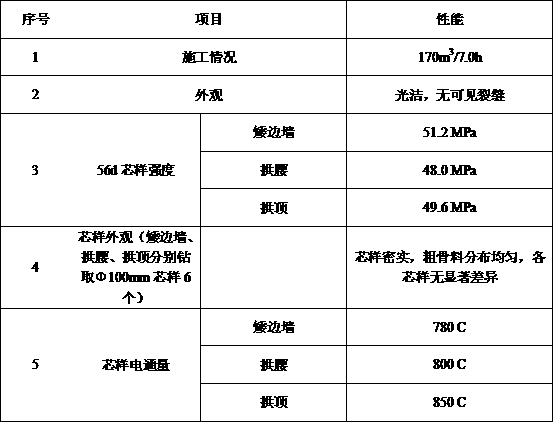

[0041] Table 6 Field application and post-test of self-filling concrete for C40 tunnel lining

[0042] ...

Embodiment 3

[0043] Example 3: The design strength of the tunnel lining self-filling concrete is C50. The concrete mix ratio used is shown in Table 7. The main properties of the tunnel lining self-filling concrete measured in the laboratory are shown in Table 8. The field application and later inspection of the tunnel lining self-filling concrete The situation is shown in Table 9.

[0044] gelling component Viscosity Adjusting Components Anti-crack component Hydration temperature rise inhibiting component aggregate water reducing component mixing water 460 0.7 43 87 1666 6.5 150

[0045] Remarks: The composition of the anti-cracking component is 40kg / m 3 Expansion agent and 3 kg / m 3 fiber composition.

[0046] project Slump spread Vibration spread Gas content Vibration U-shaped instrument filling height difference Penetration depth Initial setting time final setting time 56d compressive strength Impermeability grade 28d elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com