Adsorption resin for removing perfluorinated pollutants in water body and its preparation and application

A technology for adsorbing resins and pollutants, applied in the field of macroporous adsorption resins and their preparation, to achieve the effect of saving industrial application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

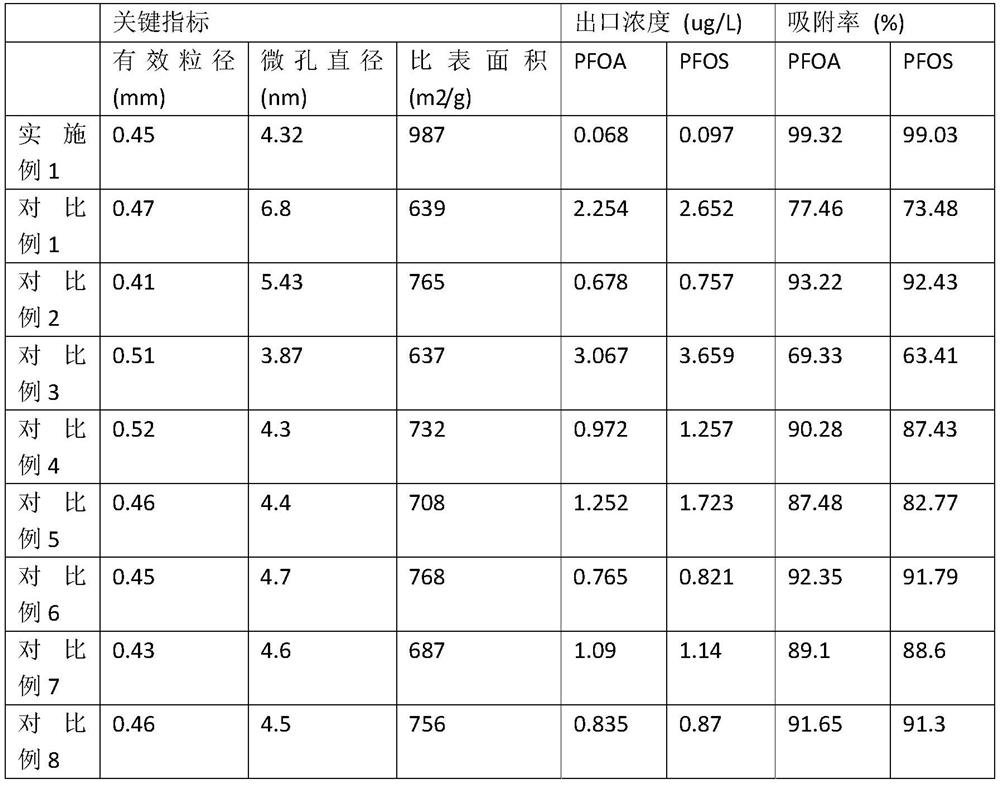

Examples

Embodiment 1

[0017] A preparation method for effectively removing perfluorinated pollutant adsorption resin in water bodies, the specific steps are as follows:

[0018] Step one suspension polymerization:

[0019] Accurately weigh 500 grams of deionized water and 4 grams of polyvinyl alcohol in the reactor according to the water phase formula, raise the temperature to 40-50 ° C, start stirring to mix all the raw materials evenly; accurately weigh in a beaker according to the oil phase formula: Divinylbenzene 100 grams, toluene 120 grams, benzoyl peroxide 1 gram, mix well;

[0020] After standing the water phase for 20 minutes, slowly add the oil phase; adjust the stirring speed so that the size of the oil droplets is distributed at 45-20 mesh; raise the temperature to 75°C, keep it warm for 3 hours, then raise the temperature to 82°C, keep it warm for 4 hours, then raise the temperature to 87°C, Keep warm for 4 hours, and the reaction is terminated;

[0021] After suction filtration, boi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com