A kind of environment-friendly agricultural dispersant and preparation method thereof

A dispersant and environment-friendly technology, applied in the field of environment-friendly agricultural dispersants and their preparation, can solve problems such as unfriendly processes, and achieve the effects of good dispersion performance and simple process synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

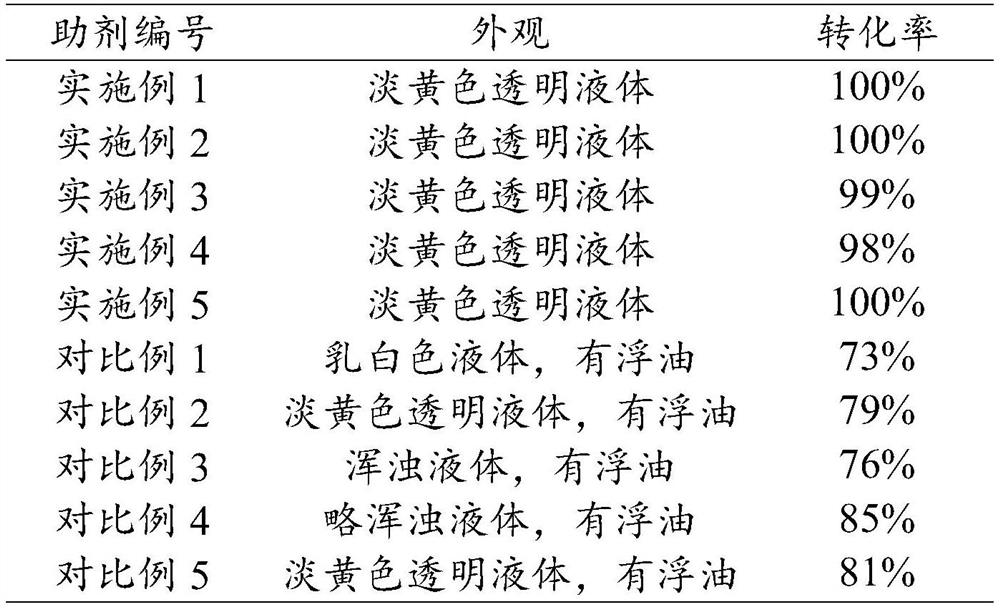

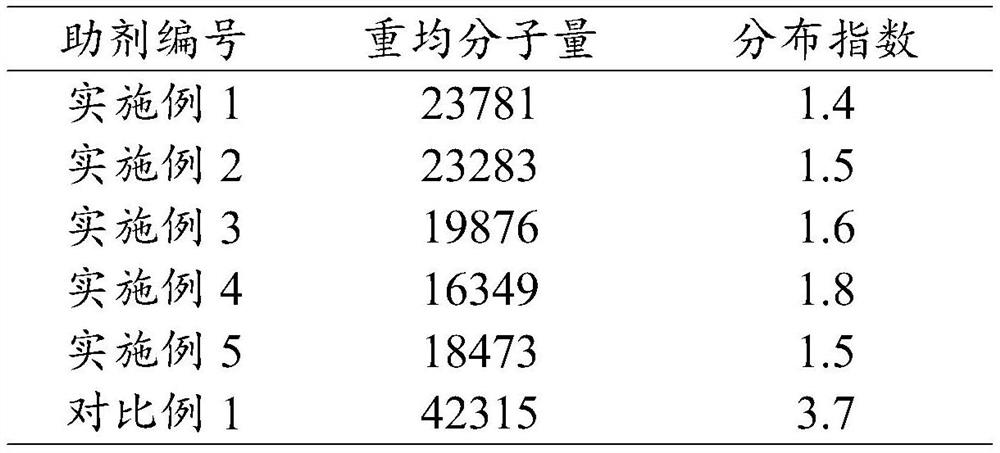

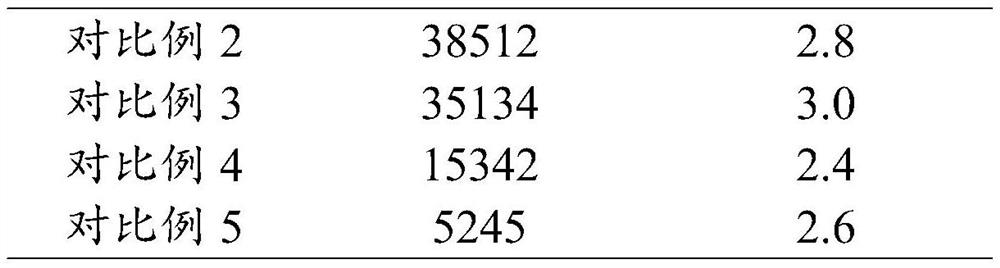

Examples

Embodiment 1

[0026] An environment-friendly agricultural dispersant, consisting of the following components in parts by weight: 66 parts of methacrylic acid, 16 parts of styrene, 17 parts of allyloxy hydroxypropyl sodium sulfonate, 5 parts of ammonium persulfate, hydrogen 31 parts of sodium oxide, 300 parts of water.

[0027] The preparation method of above-mentioned environment-friendly agricultural dispersant, concrete steps are as follows:

[0028] (1) 5g ammonium persulfate is poured into 7.5g water, is mixed with 40% initiator solution;

[0029] (2) Add 292.5g of water into the reaction kettle, then add 17g of sodium allyloxy hydroxypropyl sulfonate, 66g of methacrylic acid, and 16g of styrene in sequence, and start stirring at a stirring speed of 800 rpm;

[0030] (3) Airtight, heat up to 85°C;

[0031] (4) dripping initiator solution, the dropping time is 0.5h;

[0032] (5) After the dropwise addition, continue to keep the temperature and stir for 1h;

[0033] (6) Cool, add sodi...

Embodiment 2

[0037] An environment-friendly agricultural dispersant, consisting of the following components in parts by weight: 61 parts of maleic anhydride, 19 parts of styrene, 19.5 parts of allyloxy hydroxypropyl sodium sulfonate, 15 parts of ammonium persulfate, and 29 parts of ammonia water part, 250 parts of water.

[0038] The preparation method of above-mentioned environment-friendly agricultural dispersant, concrete steps are as follows:

[0039] (1) 15g ammonium persulfate is poured into 29g water, is mixed with 34% initiator solution;

[0040] (2) Add 221g of water into the reaction kettle, then add 19.5g sodium allyloxy hydroxypropyl sulfonate, 61g maleic anhydride, and 19g styrene in turn by weight, start stirring, and the stirring speed is 500 rpm;

[0041] (3) airtight and heat up to 95°C;

[0042] (4) dripping initiator solution, the dropping time is 3h;

[0043] (5) After the dropwise addition, continue to keep the temperature and stir for 1h;

[0044] (6) cooling, add...

Embodiment 3

[0048] An environment-friendly agricultural dispersant, consisting of the following components in parts by weight: 44 parts of acrylic acid, 27 parts of styrene, 28 parts of allyloxy hydroxypropyl sodium sulfonate, 10 parts of sodium persulfate, and 21 parts of sodium carbonate part, 200 parts of water.

[0049] The preparation method of above-mentioned environment-friendly agricultural dispersant, concrete steps are as follows:

[0050] (1) 10g sodium persulfate is poured into 23g water, is mixed with 30% initiator solution;

[0051] (2) Add 177g of water to the reaction kettle, then add 28g of allyloxy hydroxypropyl sodium sulfonate, 44g of acrylic acid, and 27g of styrene in turn by weight, start stirring, and the stirring speed is 1000 rpm;

[0052] (3) Airtight, heat up to 100°C;

[0053] (4) dripping initiator solution, the dropping time is 2h;

[0054] (5) After the dropwise addition, continue to keep the temperature and stir for 2h;

[0055] (6) Cool, add sodium ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com