Enzyme dyeing one-bath dyeing process for cotton fabric

A cotton fabric and process technology, applied in the field of textile printing and dyeing, can solve the problems of unsatisfactory treatment effect of cotton ammonia fabric, difficult to achieve one-bath dyeing, poor pretreatment effect, etc., to avoid the problem of color pattern, good surface and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

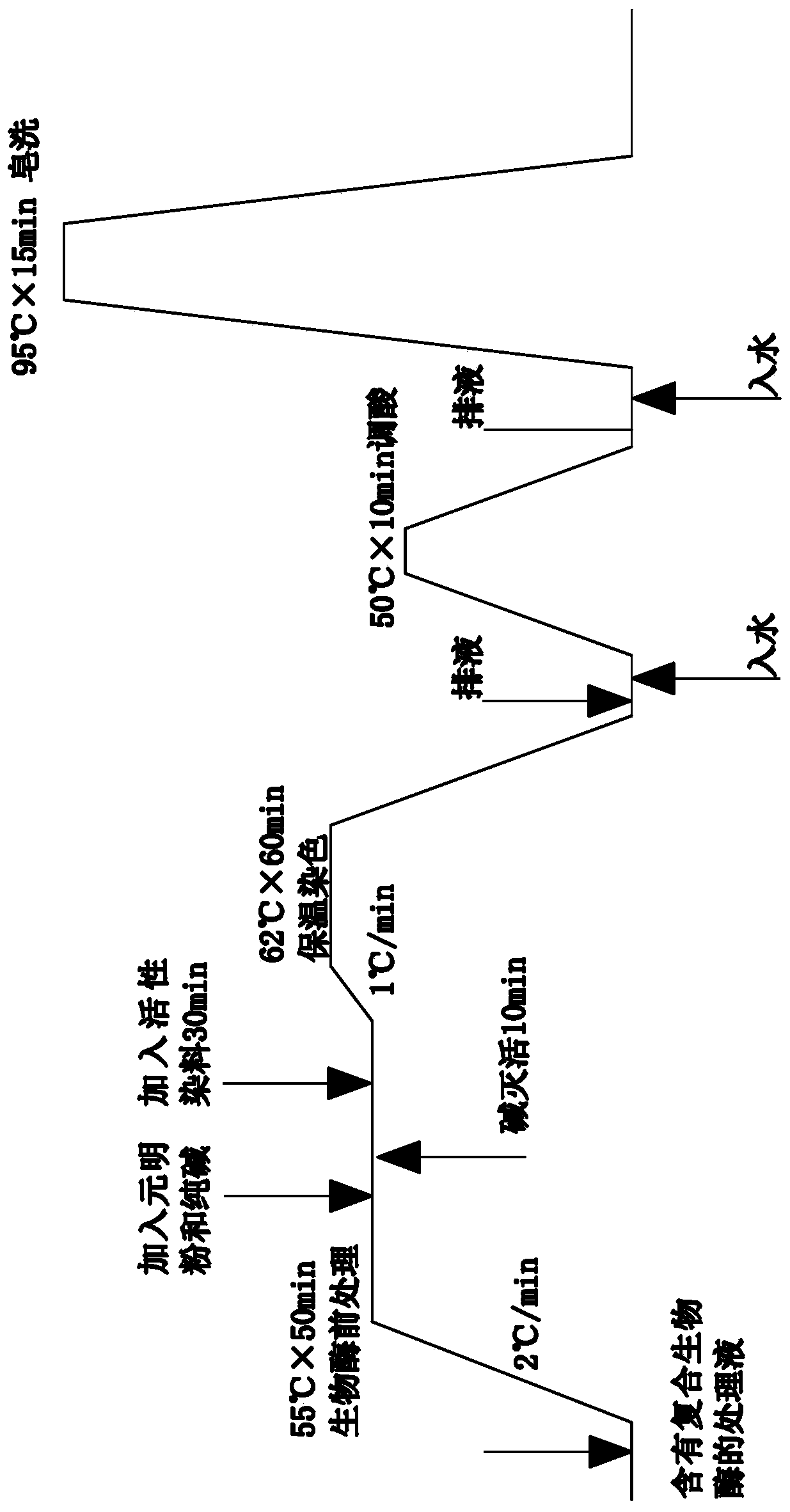

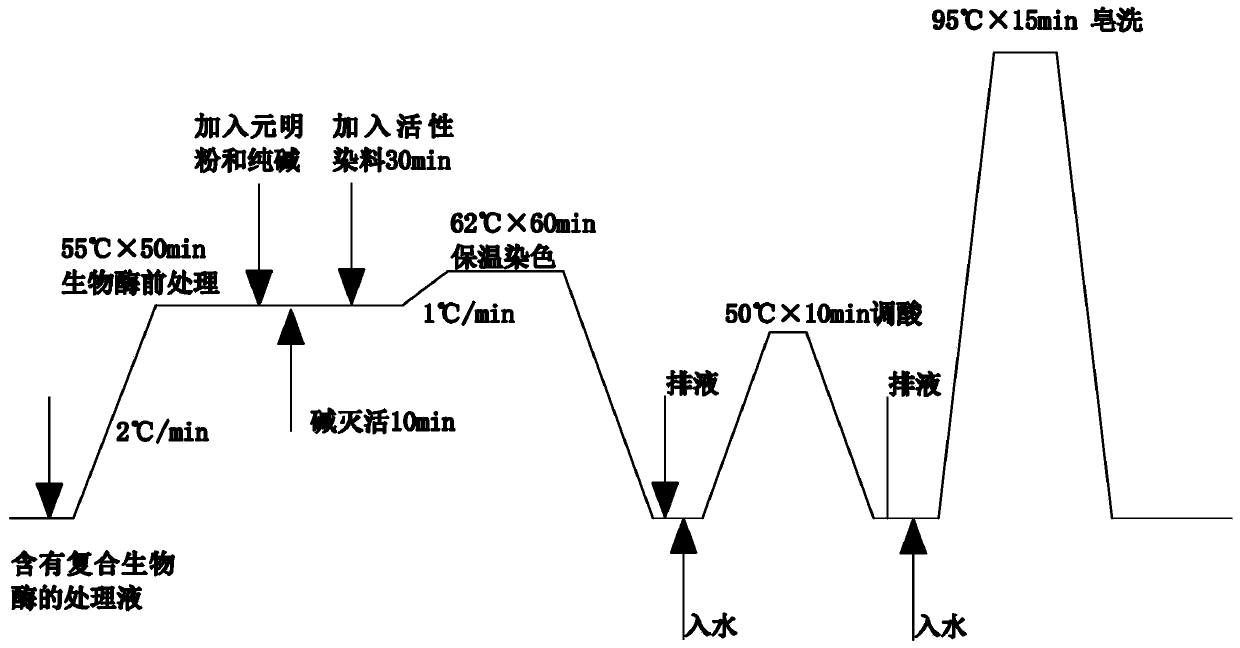

[0028] The one-bath dyeing process of cotton fabric enzyme dyeing of the present embodiment has the following steps:

[0029] ① Immerse the cotton fabric [in this example, 95% cotton + 5% spandex interwoven fabric] into the treatment solution, raise the temperature to 55°C at a rate of 2°C / min, and perform biological enzyme pretreatment for 50 minutes.

[0030] The treatment solution of this embodiment contains 1.0g / L alkaline pectin lyase, 0.35g / L neutral cellulase, 0.1g / L enriched endonuclease, 0.05g / L laccase, 0.02g / L Aqueous solution of surfactant CLD-H, 1.0g / L spandex refining degreasing agent ACR, 0.5g / L penetrating agent JFC.

[0031] Among them, the special surfactant CLD-H comes from Xi'an Chulongda Chemical Co., Ltd., the spandex refining degreasing agent ACR comes from Changzhou Xinanda Company, and the penetrant JFC comes from Shanghai Fengrui Chemical Co., Ltd.

[0032] ② Then directly add 70g / L sodium bicarbonate and 20g / L soda ash to the treatment liquid in ste...

Embodiment 2~ Embodiment 5)

[0037] The cotton fabric enzyme dyeing one-bath dyeing process of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0038] Table 1

[0039] Example 1 Example 2 Example 3 Example 4 Example 5 cotton fabric 95% cotton + 5% spandex interwoven fabric 65% cotton + 35% polyester blended fabric 100% cotton fabric 95% cotton + 5% spandex interwoven fabric 95% cotton + 5% spandex interwoven fabric alkaline pectin lyase 1.0g / L 1.0g / L 1.0g / L 1.0g / L 1.0g / L neutral cellulase 0.35g / L 0.35g / L 0.35g / L 0.25g / L 0.40g / L Enriched endonuclease 0.1g / L 0.1g / L 0.1g / L 0.15g / L 0.08g / L Laccase 0.05g / L 0.05g / L 0.05g / L 0.1g / L 0.02g / L Surfactant CLD-H 0.02g / L 0.02g / L 0.02g / L 0.02g / L 0.02g / L Spandex Refining Degreaser ACR 1.0g / L / / 1.1g / L 0.9g / L Penetrant JFC 0.5g / L 0.5g / L 0.5g / L 0.4g / L 0.6g / L

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com