Electronic waste treating device and use method thereof

A technology of electronic waste and combustion furnace, which is applied in the direction of furnace control device, waste heat treatment, furnace type, etc., can solve the problems of long time period for microbial treatment, environmental hazards, and difficult treatment, so as to save the pretreatment plant and equipment, The effect of saving initial investment and broad prospects for comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

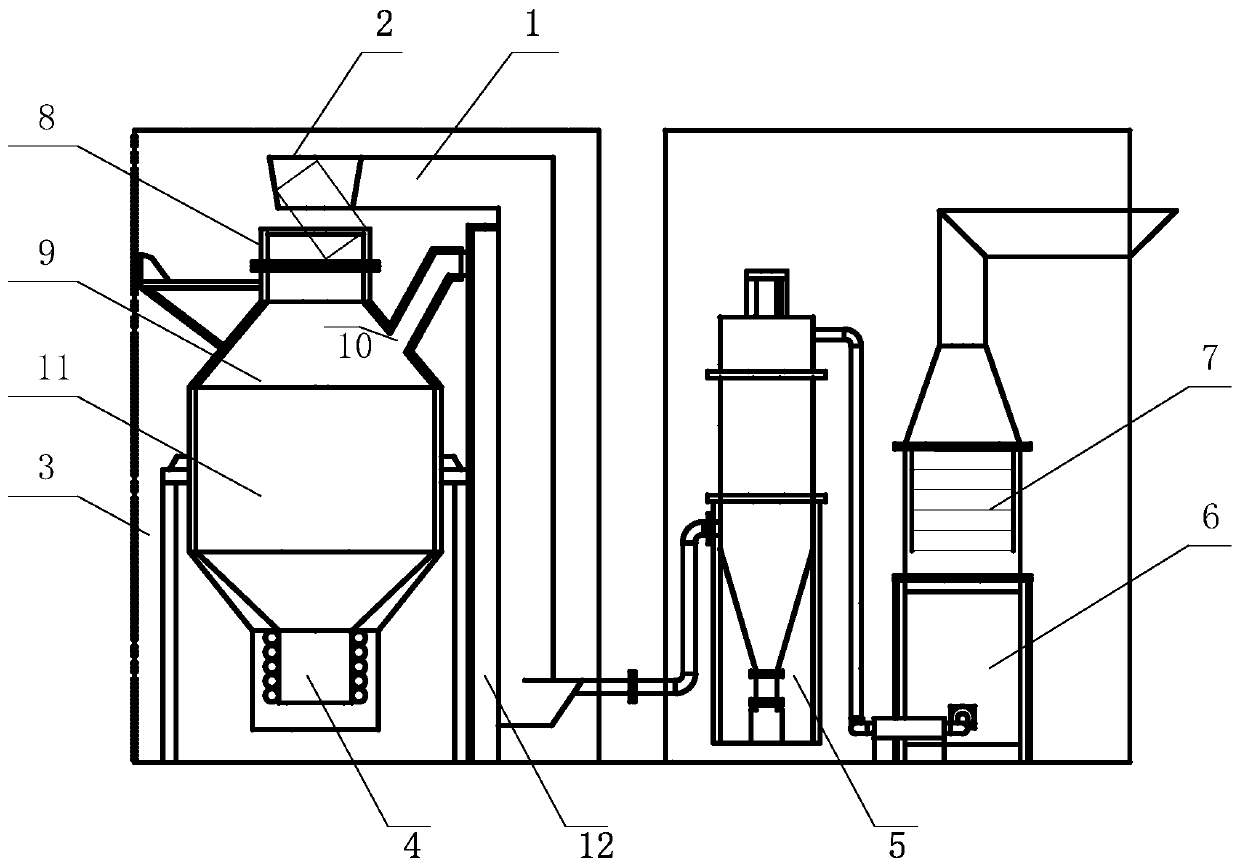

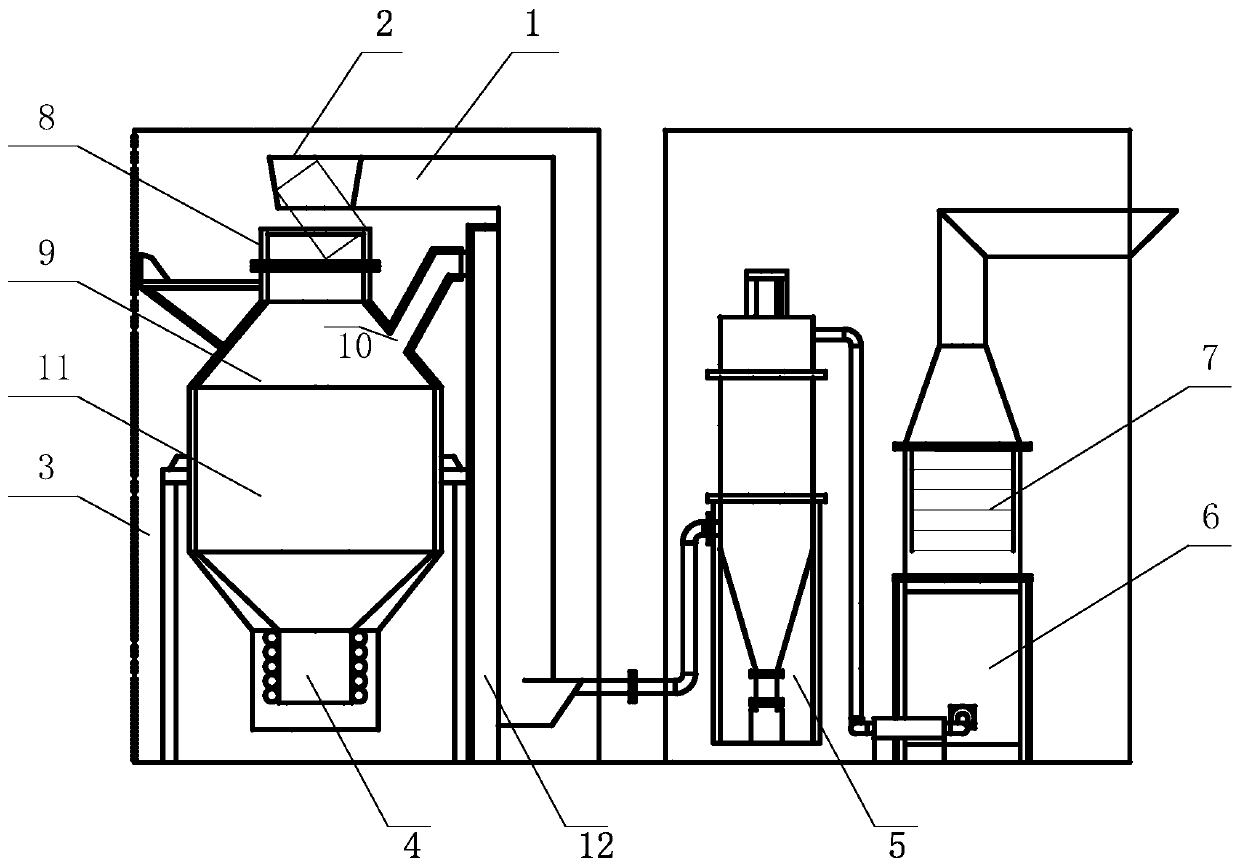

[0053] Attached below figure 1 The device for processing electronic waste and its use method of the present invention will be described in detail.

[0054] A device for processing electronic waste. The device uses a low-carbon direct smelting reduction reactor. The low-carbon direct smelting reduction reactor includes a lift 1, an input tank 2, a furnace body 3, an induction furnace 4, a dust collector 5, Combustion furnace 6 and heat exchanger 7; wherein, the furnace body includes a feed port 8, a feed section 9, a combustible gas outlet 10, and a reduction and melting section 11; the feed port is arranged on the top of the furnace body, the The input tank is fixedly arranged on the feed port; the feed section is connected with the feed port; the combustible gas outlet is provided on the top side of the reduction melting section; the feed section is connected with the reduction melting section; The induction furnace is connected with the reduction melting section; the elevator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com