A two-component quick-setting slurry rheological parameter testing device and testing method

A technology of rheological parameters and testing methods, which is applied to the measurement of direct current flow characteristics, etc., can solve the problems of inability to test rheological parameters and obtain the yield stress of slurry, and achieve effective and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In a typical embodiment of the present invention, the slurry to be tested is a self-developed two-component quick-setting slurry, and the self-developed slurry is composed of component A and component B. Component A is cement slurry, and component B is a quick-setting agent with water glass as the main agent and high molecular polymer as the additive. When component A and component B are mixed in a specific proportion, the slurry will gradually gel and solidify. In this example, the water-cement ratio of component A cement slurry is W / C=1, and the volume ratio of component A cement slurry to component B quick-setting agent is 3:1.

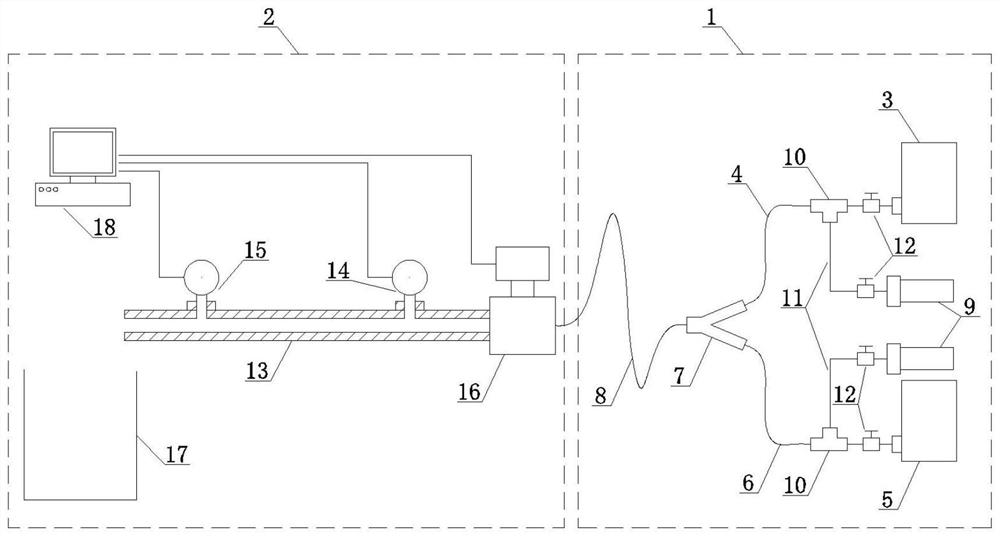

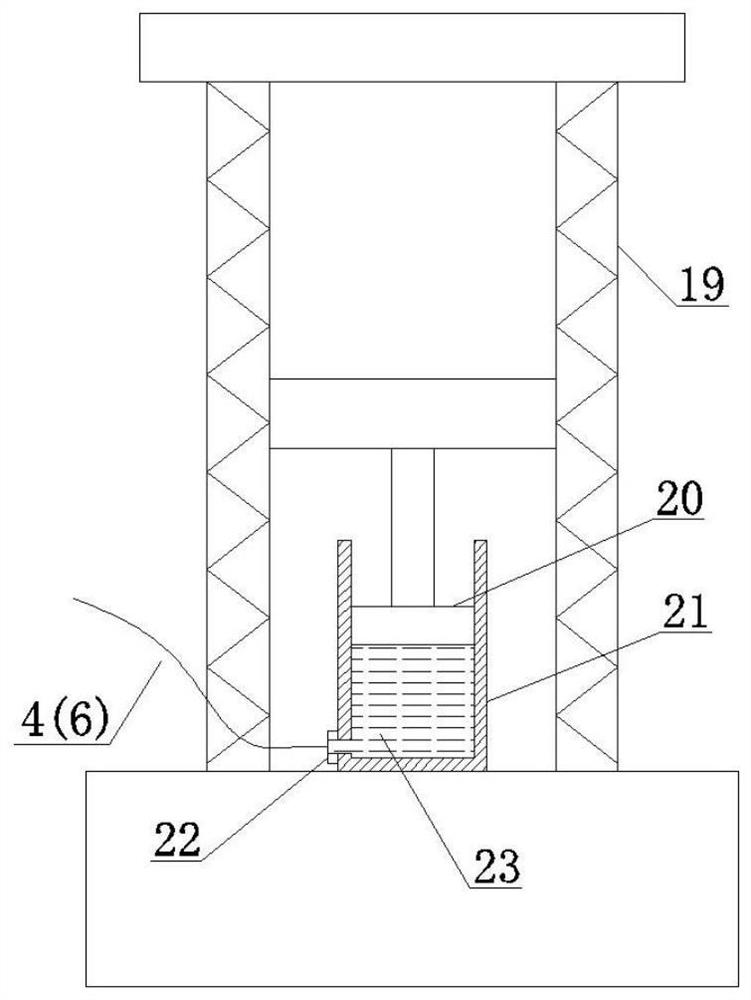

[0051] The device for testing the rheological parameters of the two-component quick-setting slurry in this embodiment includes two modules, namely, the slurry delivery module 1 and the measurement module 2 . The grouting module 1 includes component A constant rate grouting pump 3, component A grouting pipe 4, component B constant rate grouti...

Embodiment 2

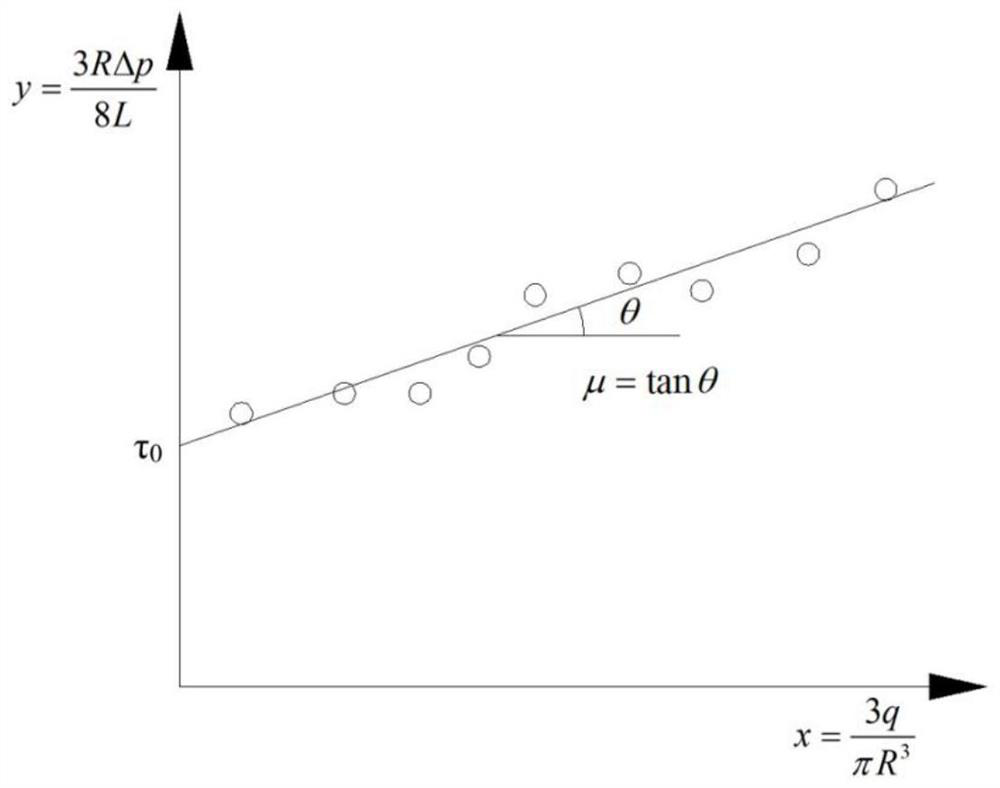

[0060] This embodiment provides the method for testing the rheological parameters of the two-component quick-setting slurry, and the specific steps are:

[0061] 1) Determine the component category and component distribution ratio of the two-component quick-setting slurry to be tested, determine the gel time range 0-T and the gel time gradient T / n of the grout to be tested, and determine the flow range Q of the grout 1 ~Q 2 and slurry flow gradient (Q 2 -Q 1 ) / m;

[0062] 2) Assemble the slurry delivery module and measurement module of the rheological parameter testing device, and put the specified component A and component B into the slurry storage tank respectively;

[0063] 3) Set the slurry gel time t=0 and the slurry flow rate q=Q of the first group of experiments 1 ;

[0064] 4) Determine the length of the double-liquid slurry delivery pipe according to the gelation time t of the serous fluid, the flow rate of the serous fluid q, and the inner diameter of the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com