Fuel cell metal bipolar plate regional runner

A metal bipolar plate, fuel cell technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of insufficient electrochemical reaction, low reactant flow rate, slow gas flow rate, etc., to promote electrochemical Responsiveness, uniform distribution, and the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

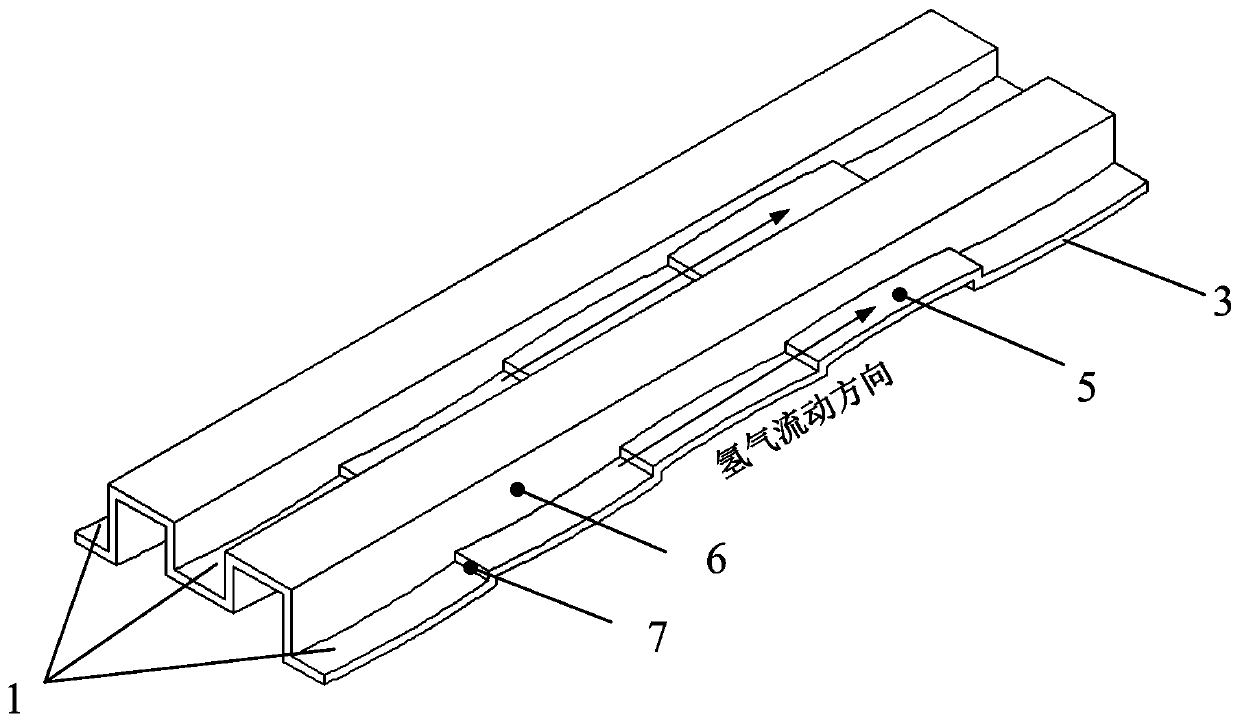

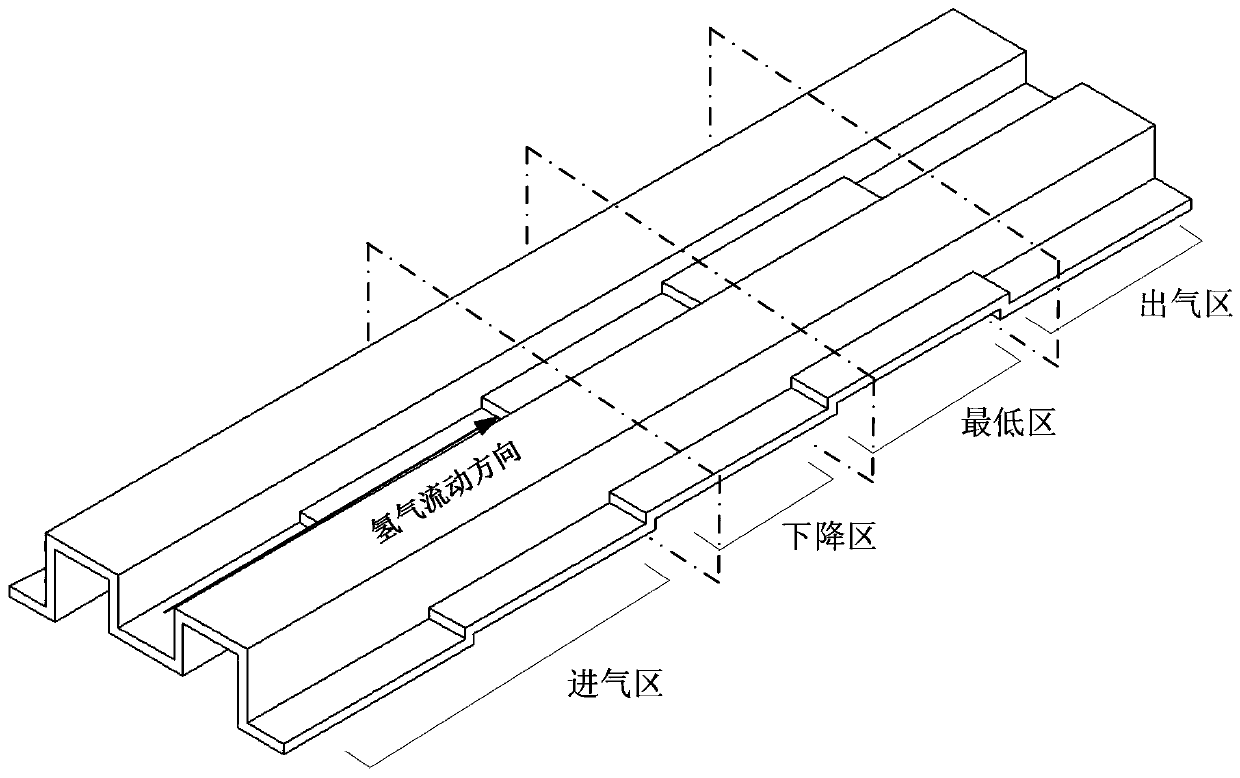

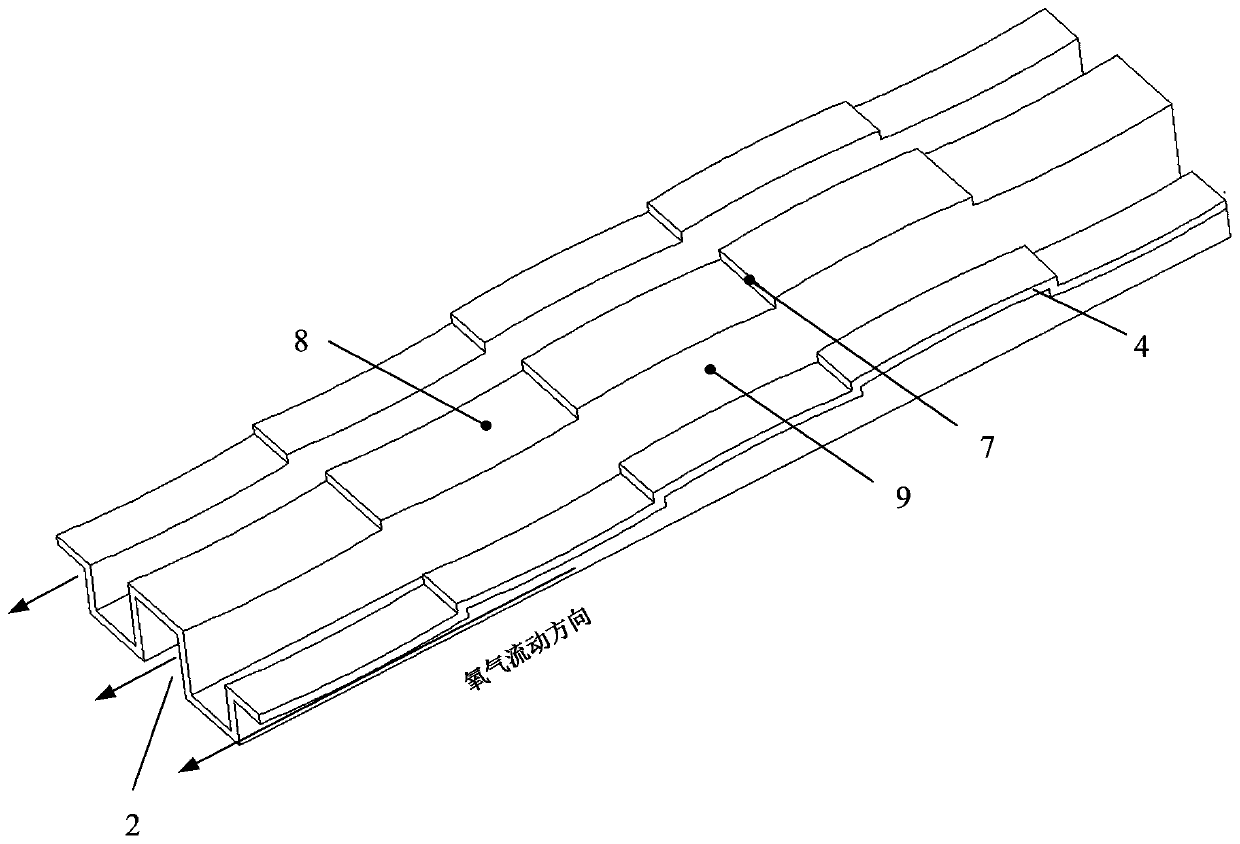

[0055] Figure 1 ~ Figure 4 As shown, a fuel cell metal bipolar plate sub-area flow channel includes an oxygen flow channel 2 provided on the cathode unipolar plate 4, a hydrogen flow channel 1 provided on the anode unipolar plate 3, and the cathode unipolar plate The plate 4 is convex-convex symmetrical to the anode unipolar plate 3, wherein each hydrogen flow channel 1 includes a hydrogen flow channel intake area, a hydrogen flow channel descending area, a hydrogen flow channel lowest area and a hydrogen flow channel along the gas flow direction. In the gas outlet area of the flow channel, the inlet area of the hydrogen flow channel includes at least two inlet steps, the descending area of the hydrogen flow channel includes at least one descending step, and the lowest area of each hydrogen flow channel includes a lowest step. The gas outlet area of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com