Liquid cooling heat dissipation assembly for cooling high-voltage motor driver

A high-voltage motor, liquid-cooled heat dissipation technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of low heat generation of motor drivers, inability to meet heating power, and poor cooling effect. , to achieve the effect of improving heat dissipation, preventing salt corrosion and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

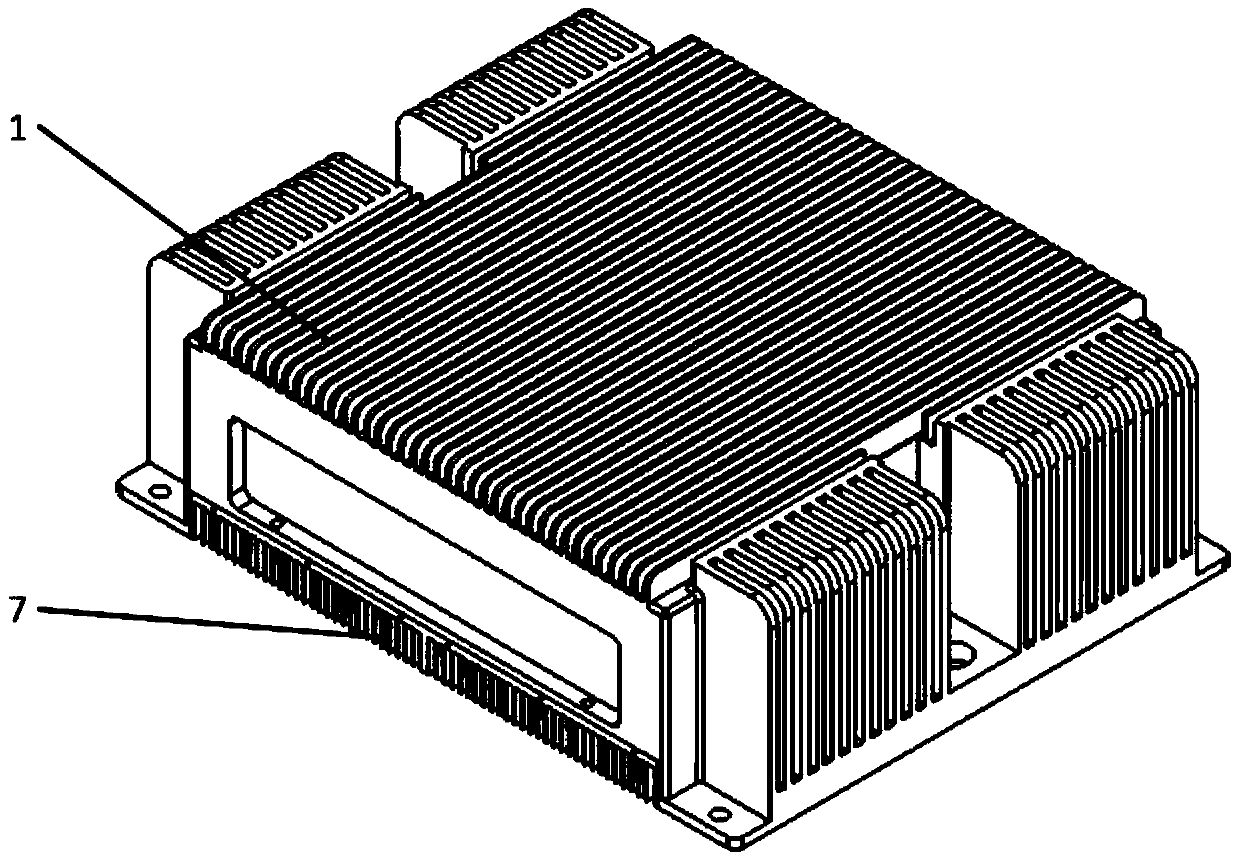

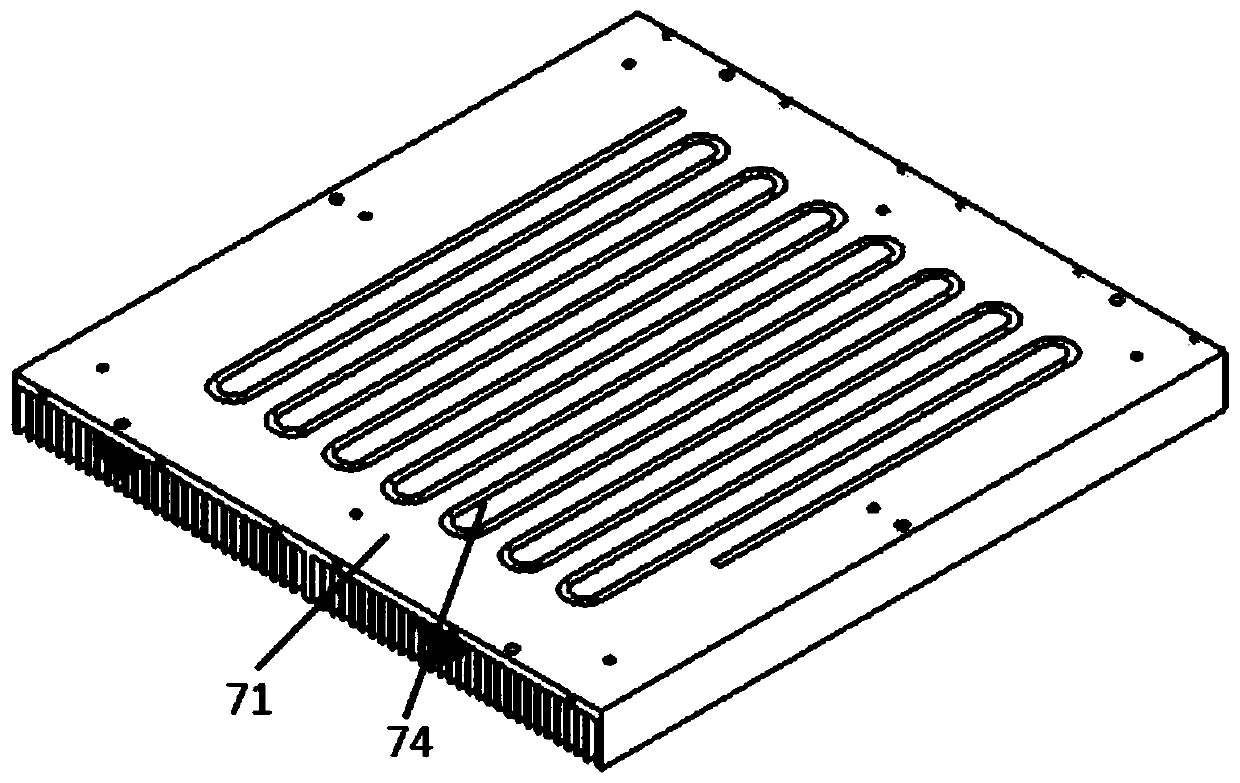

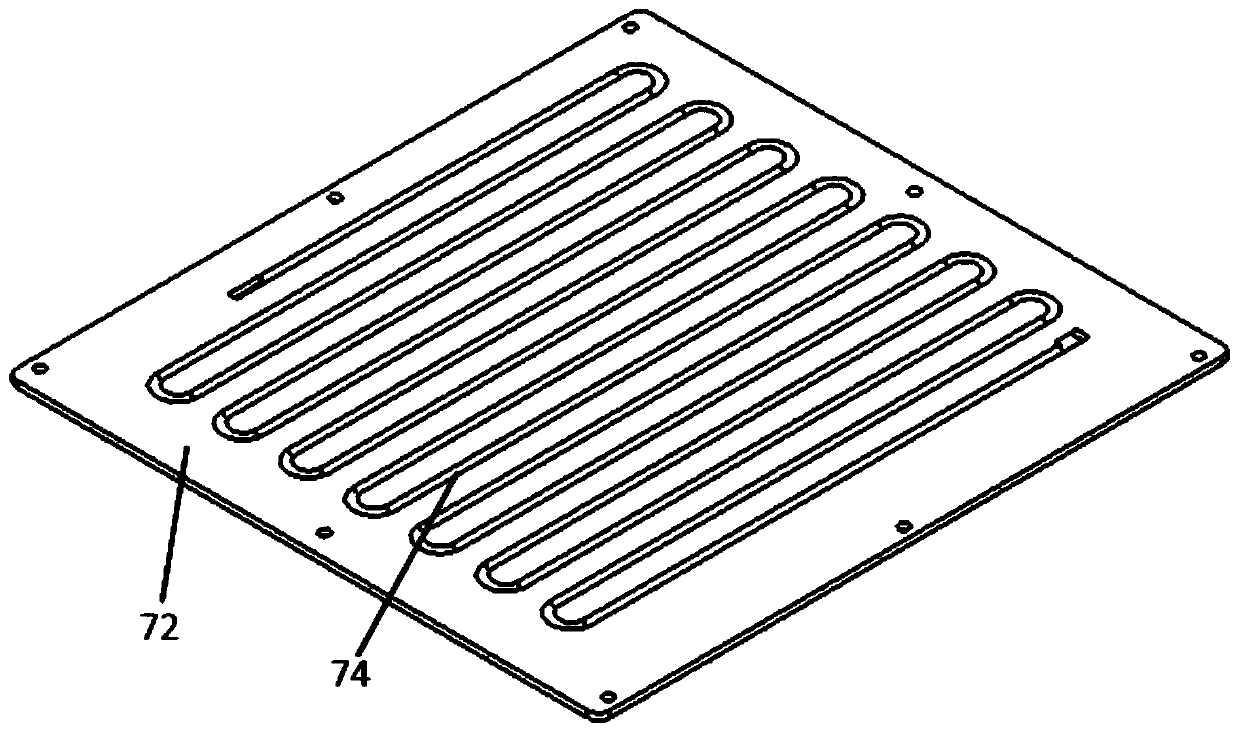

[0030] The present invention provides a liquid-cooled heat dissipation assembly (referred to as heat dissipation assembly, referred to Figure 1-11 ), including a housing 1, a heat dissipation assembly 7, a water channel 6, a circulating water pump 3 and a circulating water pump controller 5, and the heat dissipation assembly 7 includes a heat dissipation fin plate 71, a heat dissipation plate 72 and a serpentine pipe 73;

[0031] The heat dissipation plate 72 is fixed on the heat dissipation fin plate 71, and the bottom of the heat dissipation fin plate 71 is provided with heat dissipation fins; the bottom of the heat dissipation plate 72 and the top of the heat dissipation fin plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com