Hybrid drive train

A technology of hybrid power and drive train, applied in the direction of hybrid vehicles, power devices, electric power devices, etc., to achieve the effect of reducing structural space requirements and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

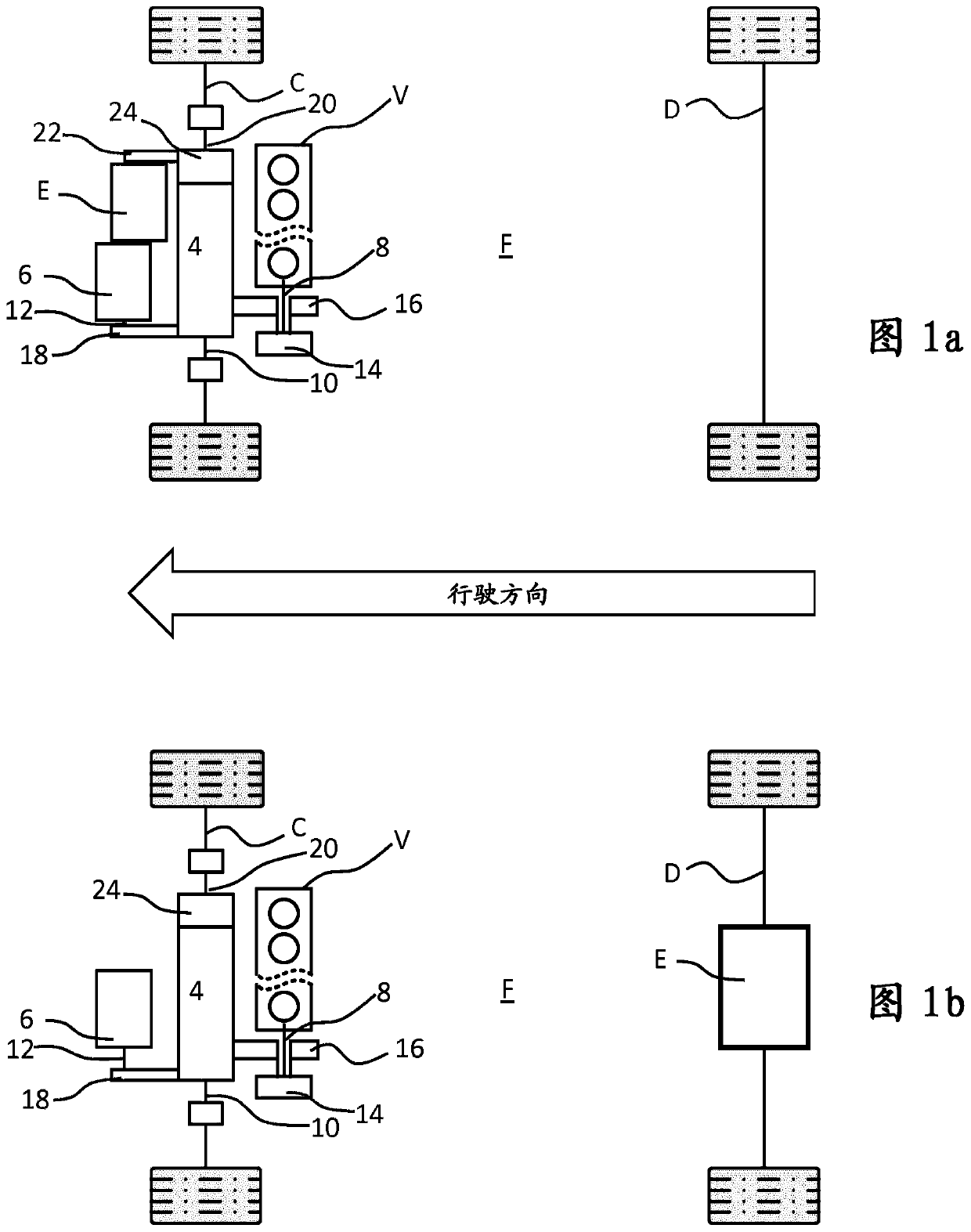

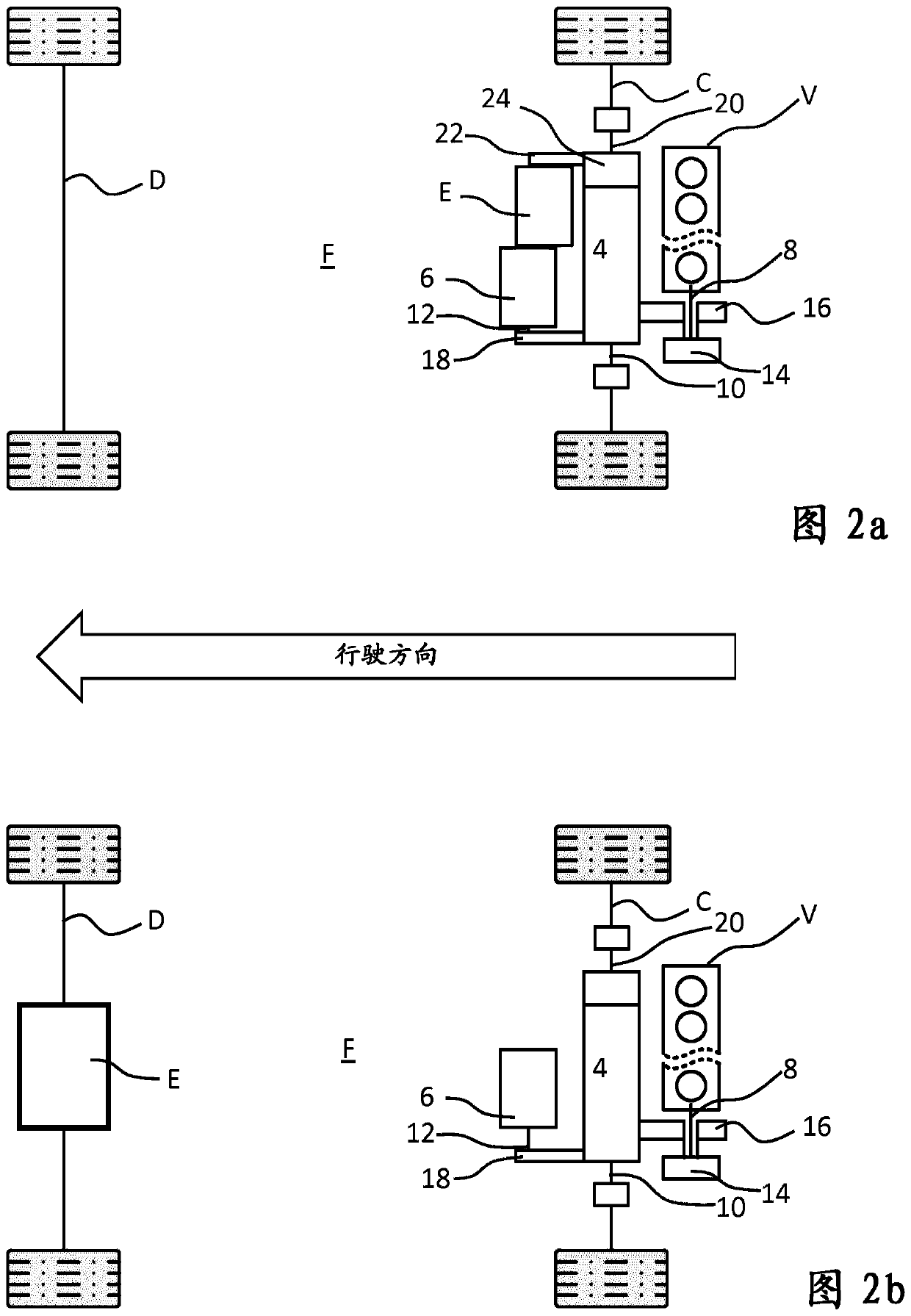

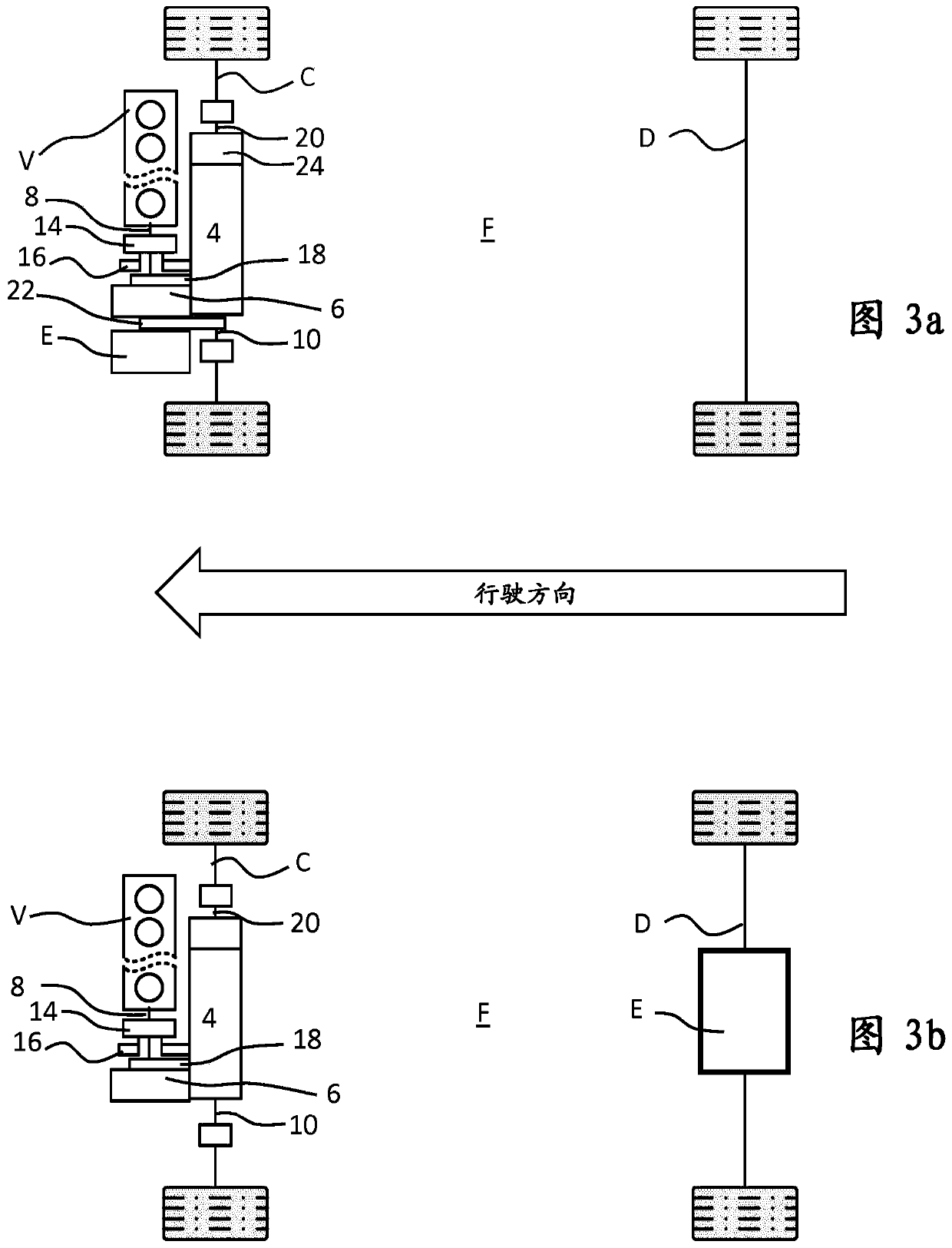

[0038] FIGS. 1 to 3 show, in sub-figures a and b, schematic representations of two variants of a vehicle 100 with a hybrid drive train 1 , wherein the hybrid drive train 1 has two drive units, namely an internal combustion engine V and a Motor E. The two drive units V and E provide torque with which drive shafts C and / or D and thus at least one wheel can be driven. Here, the variants of sub-figures a and b differ in that, in variant a, the internal combustion engine V and the electric motor E drive the same drive shaft C; in variant b, the internal combustion engine V and the electric motor E drive different shafts C and D. Furthermore, it can be seen from the figure that the hybrid drive train comprises a transmission 4 with a transmission input shaft 10 in order to transmit torque from the internal combustion engine V via its internal combustion engine drive shaft 8 on the transmission input side to the transmission input shaft 10 and in the transmission The output side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com