Aronia melanocarpa fruit compound juice beverage with anti-aging function and preparation method of aronia melanocarpa fruit compound juice beverage

A technology of Aronia nigra and compound juice, which is applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problem that the health of the drinker cannot be achieved, the anti-aging effect is not much, and it is impossible to achieve and other problems, to achieve rapid and obvious anti-aging effects, enhance anti-aging effects, and improve physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

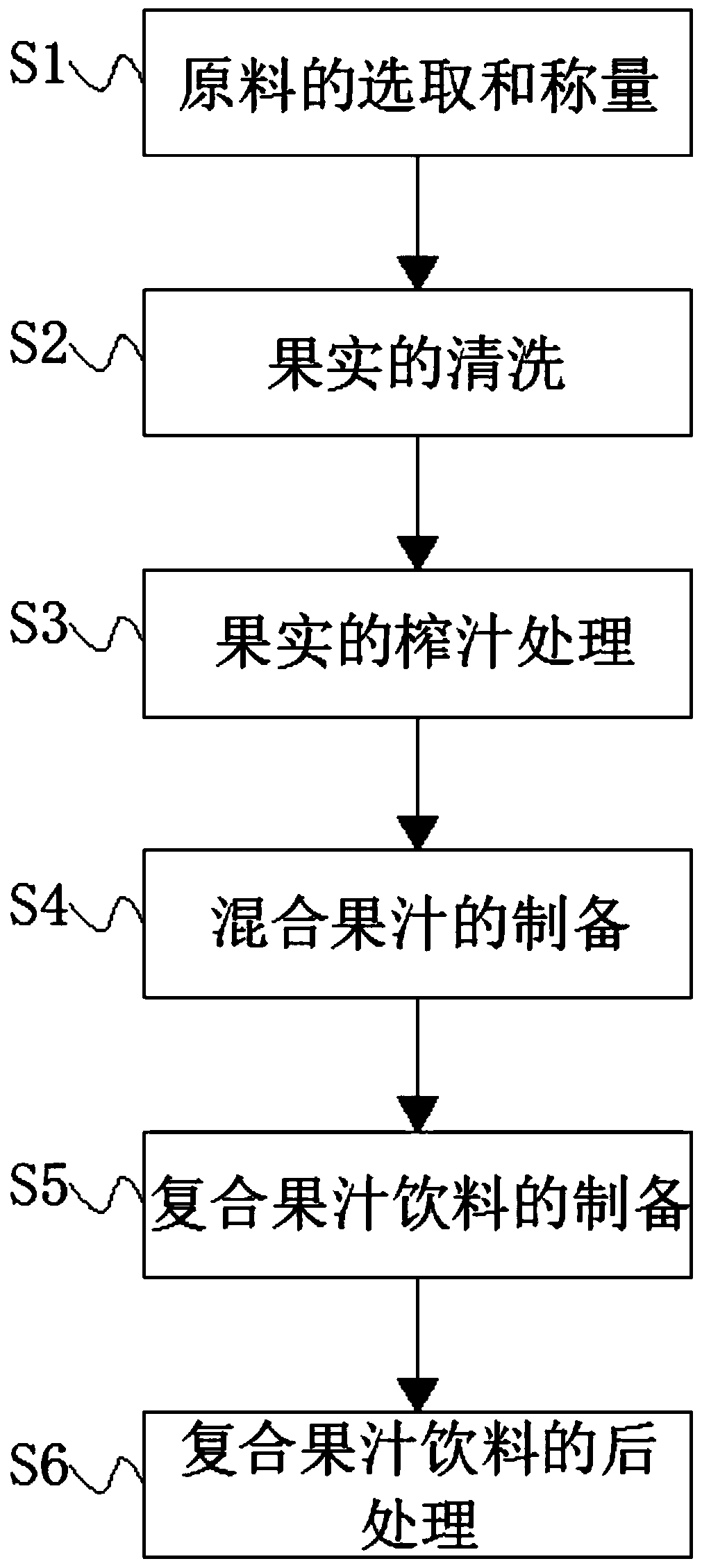

[0025] S1, the selection and weighing of raw materials: first select 25 parts of Arana berries, 7 parts of medlar, 7 parts of strawberry juice, 4 parts of sealwort, 7 parts of lily juice, 7 parts of hawthorn, 7 parts of jujube juice, 7 parts of seabuckthorn, 4 parts of sucrose, 2 parts of citric acid and 0.7 part of potassium sorbate, and store these selected ingredients in storage tanks for later use. Seabuckthorn and seabuckthorn are fresh fruits that are full of fruit and free from diseases and insect pests;

[0026] S2, cleaning of fruit: Pour the black fruit Arrowberry, Lycium barbarum, Polygonatum, Hawthorn and Hippophae rhamnoides weighed in step S1 into the cleaning pool in turn, first rinse twice with clean water, and then pass each fruit after washing through clean water Rinse for 7 minutes, and finally start the ultrasonic cleaning equipment to perform 17 minutes of ultrasonic cleaning on the required fruits, take out and drain;

[0027] S3. Juicing treatment of fr...

Embodiment 2

[0032] S1. Selection and weighing of raw materials: firstly select 20 parts of Arana berries, 5 parts of medlar, 5 parts of strawberry juice, 3 parts of sealwort, 5 parts of lily juice, 5 parts of hawthorn, 5 parts of jujube juice, 5 parts of seabuckthorn, 3 parts of sucrose, 1 part of citric acid and 0.5 part of potassium sorbate, and store the selected ingredients in a storage tank for later use. Seabuckthorn and seabuckthorn are fresh fruits that are full of fruit and free from diseases and insect pests;

[0033]S2, cleaning of fruit: Pour the black fruit Arrowberry, Lycium barbarum, Polygonatum, Hawthorn and Hippophae rhamnoides weighed in step S1 into the cleaning pool in turn, first rinse twice with clean water, and then pass each fruit after washing through clean water Rinse for 5 minutes, and finally start the ultrasonic cleaning equipment to perform 15 minutes of ultrasonic cleaning on the required fruits, take out and drain;

[0034] S3. Juicing treatment of fruit: ...

Embodiment 3

[0039] S1, the selection and weighing of raw materials: first select 30 parts of Arana adenocarba, 10 parts of medlar, 10 parts of strawberry juice, 5 parts of sealwort, 10 parts of lily juice, 10 parts of hawthorn, 10 parts of jujube juice, 10 parts of seabuckthorn, 5 parts of sucrose, 3 parts of citric acid and 1 part of potassium sorbate, and store the selected ingredients in a storage tank for later use, black fruit arboria, medlar, hawthorn Seabuckthorn and seabuckthorn are fresh fruits that are full of fruit and free from diseases and insect pests;

[0040] S2, cleaning of fruit: Pour the black fruit Arana berries, Lycium barbarum, Polygonatum, Hawthorn and Hippophae rhamnoides weighed in step S1 into the cleaning pool in turn, first rinse with clean water for 3 times, and then rinse each fruit with clean water Rinse for 10 minutes, and finally start the ultrasonic cleaning equipment to perform 20 minutes of ultrasonic cleaning on the required fruits, take out and drain;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com