Flue gas desulfurization device and flue gas desulfurization method

A desulfurization device and flue gas technology, which can be used in combination devices, separation methods, chemical instruments and methods, etc., can solve problems such as low removal efficiency, and achieve the effects of high removal efficiency, simple equipment and compact layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

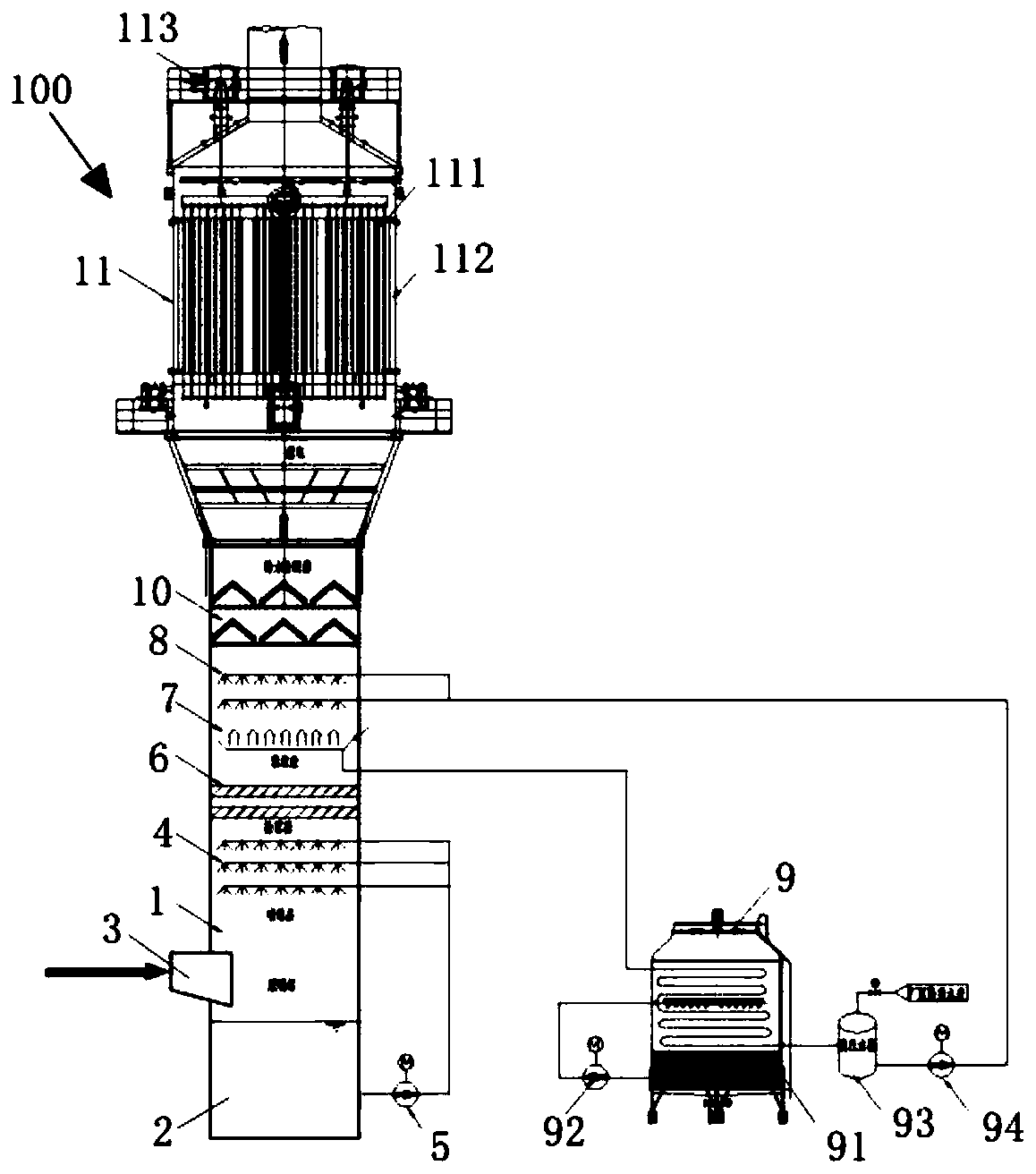

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0033] Such as figure 1 As shown, the flue gas desulfurization device 100 of the present invention includes: a desulfurization tower 1, a slurry tank 2, an air inlet 3, a spray layer 4, a slurry circulation pump 5, a mist eliminator 6, a liquid collecting pan 7, a water washing cooling layer 8, Condensation circulation system 9, dewatering and deacidification device 10, and wet electric precipitator 11.

[0034] The slurry tank 2 is arranged at the bottom of the desulfurization tower 1, the gas inlet 3 is connected with the desulfurization tower 1 and is located above the slurry tank 2, and the spray layer 4 is arranged above the gas inlet 3, For spraying the desulfurization slurry, the mist eliminator 6 is arranged above the spray layer 4 to inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cut circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap