Double-layer skin wave-absorbing honeycomb sandwich structure and preparation method thereof

A technology of honeycomb sandwich and skin, which is applied in chemical instruments and methods, laminated, layered products, etc., and can solve problems such as difficulty in obtaining wave-absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

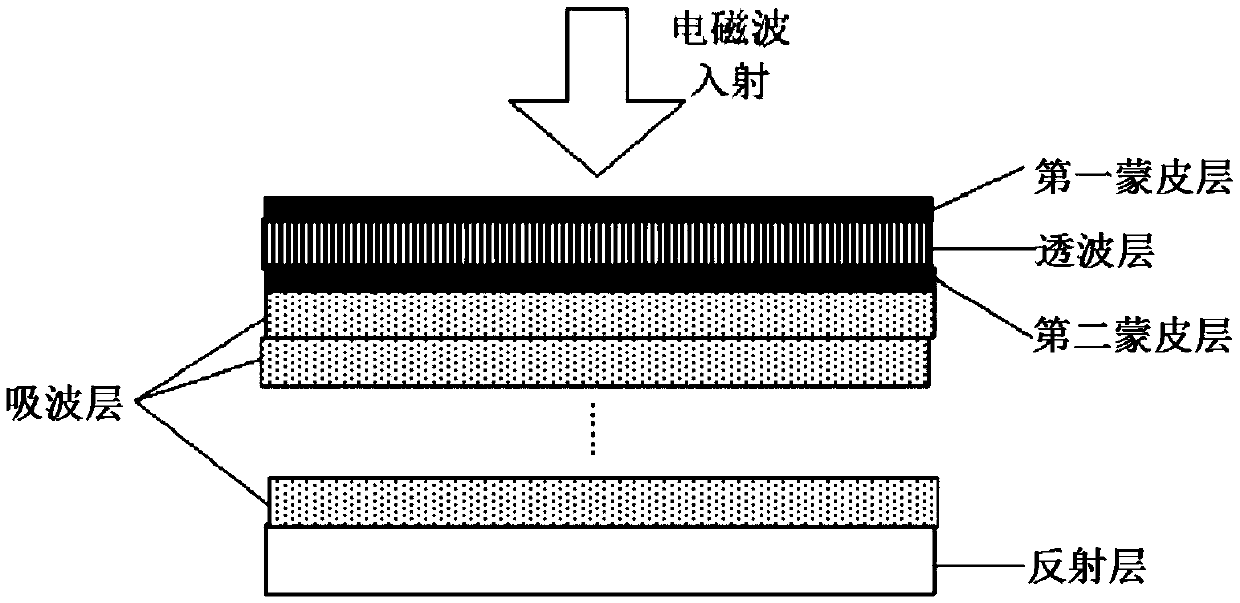

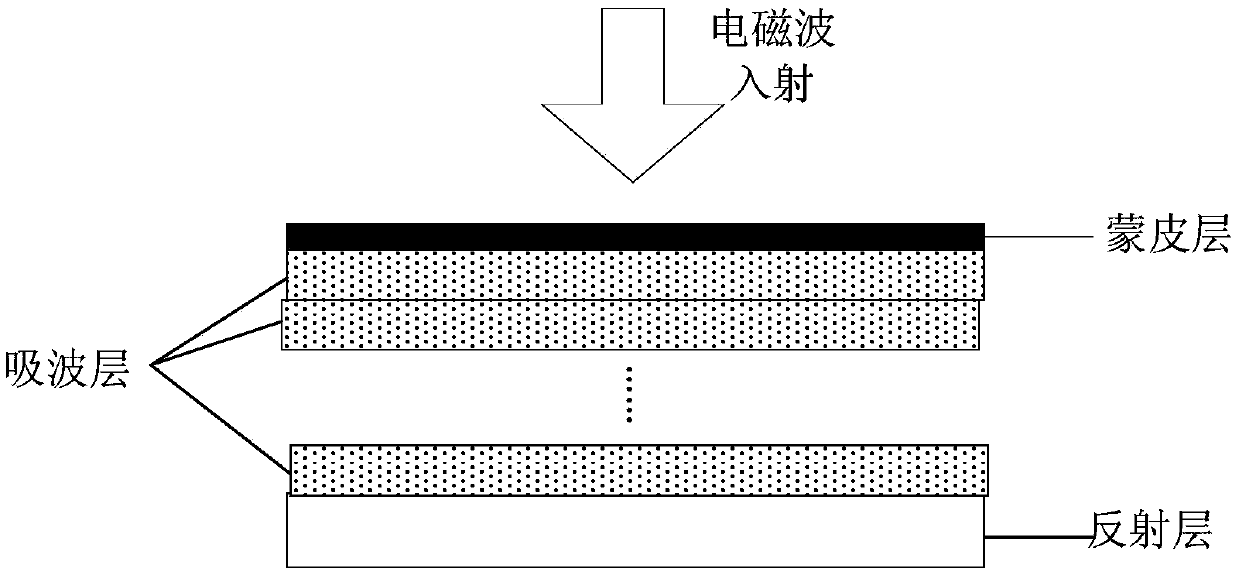

[0048] According to another aspect of an embodiment of the present invention, a method for preparing a double-skinned wave-absorbing honeycomb sandwich structure is provided, including the following steps:

[0049] Step 1, laying layers on the mold in the order of the first skin layer, wave-transmitting layer, second skin layer, several wave-absorbing layers and reflective layers, and connecting each layer with an adhesive;

[0050] In this step, the first skin layer, the wave-transmitting layer, the second skin layer, several layers of wave-absorbing layers, and the reflective layer materials need to be cut to the required size before laying the layers. In addition, a mold release agent needs to be sprayed on the surface of the mold , and dry, when laying layers, each layer needs to be aligned;

[0051] Step 2, curing the multi-layer material prepared in step 1 to obtain a double-skinned wave-absorbing honeycomb sandwich structure blank.

[0052] In this step, as required, t...

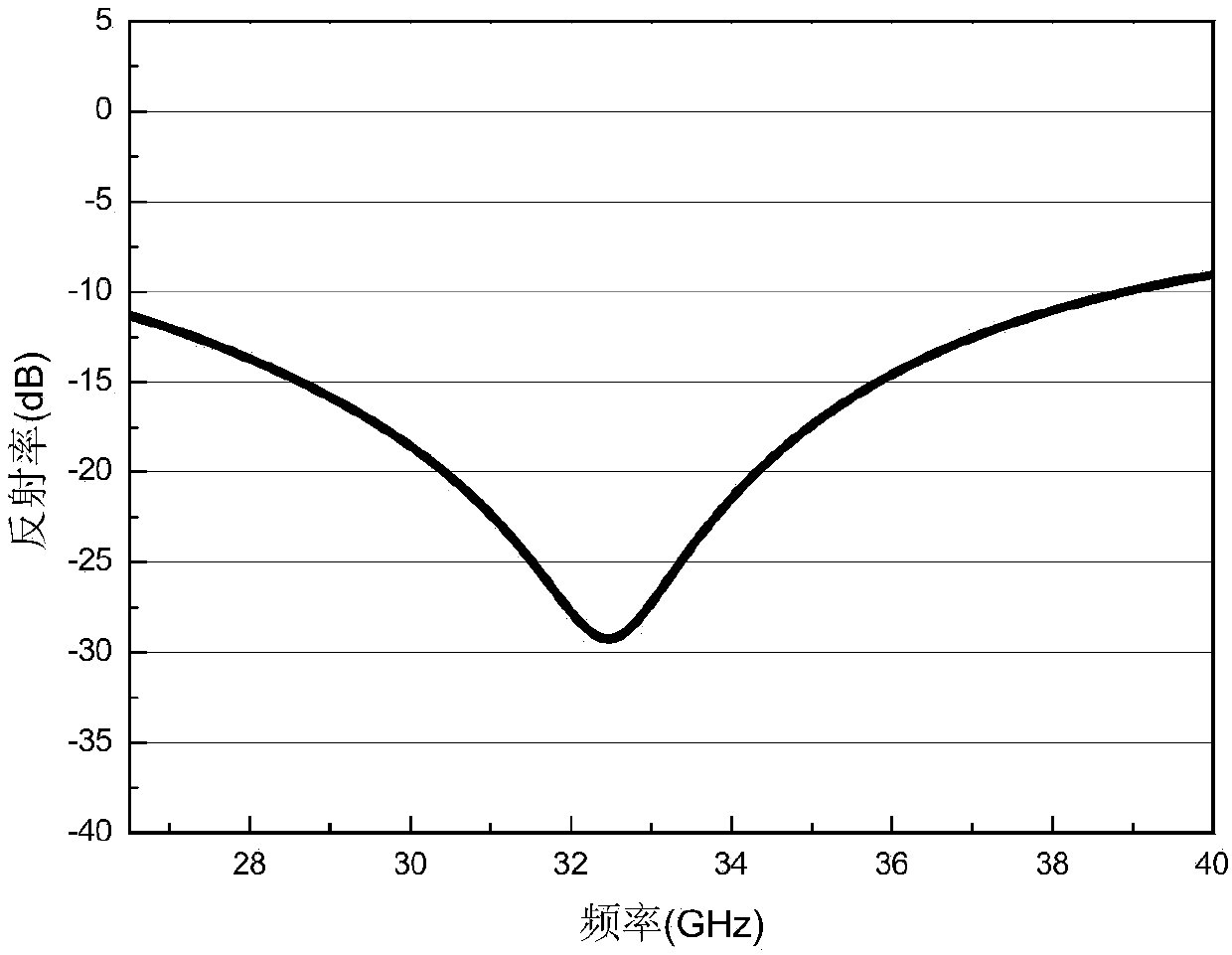

Embodiment 1

[0060] In the double-skinned wave-absorbing honeycomb sandwich structure provided in this embodiment, the materials used in the first skin layer and the second skin layer are both glass fiber fabric reinforced resin composite materials with a thickness of 1 mm; the materials used in the wave-transmissive layer are It is an aramid paper honeycomb with a thickness of 0.5mm; the wave-absorbing layer has 4 layers in total. The mass fractions of carbon black in the four absorbing layers in the direction are 0.1%, 0.5%, 2%, and 4% respectively; the material used for the reflective layer is carbon fiber fabric reinforced resin composite material.

[0061] The preparation method of the present embodiment comprises the following steps:

[0062] 1. Cut glass fiber fabric reinforced resin prepreg, aramid paper honeycomb, wave absorbing honeycomb, carbon fiber fabric reinforced resin composite materials to the required size;

[0063] 2. Spray the release agent on the surface of the mold ...

Embodiment 2

[0077] In the double-skinned wave-absorbing honeycomb sandwich structure provided in this embodiment, the materials used in the first skin layer and the second skin layer are both quartz fiber fabric reinforced resin composite materials with a thickness of 0.6 mm; The material is epoxy honeycomb with a thickness of 1.1mm; the wave-absorbing layer has 4 layers in total. direction, the mass fractions of carbon black in the four absorbing layers are 0.1%, 0.5%, 2%, and 4% respectively; the reflective layer is made of carbon fiber fabric reinforced resin composite.

[0078]The preparation method of the present embodiment comprises the following steps:

[0079] 1. Cut quartz fiber fabric-reinforced resin prepreg, aramid paper honeycomb, wave-absorbing honeycomb, and carbon fiber fabric-reinforced resin composite materials to the required size;

[0080] 2. Spray the release agent on the surface of the mold and let it dry;

[0081] 3. Lay quartz fiber fabric reinforced resin prepre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com