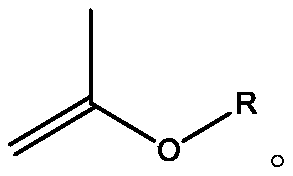

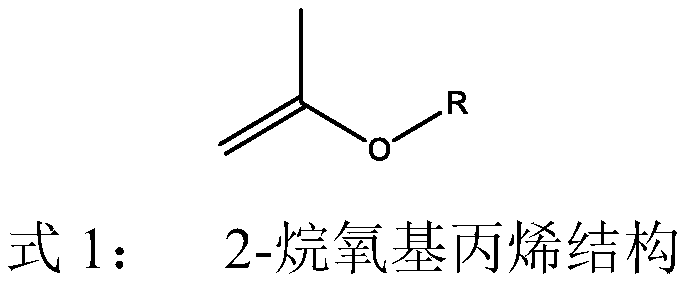

Method for preparing 2-alkoxy propylene

A technology of alkoxypropene and dialkoxypropane, which is applied in the field of preparation of 2-alkoxypropene, can solve the problems of difficult separation, increase, and many side reactions, achieve high conversion rate of cracking reaction, reduce three wastes, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In a tower reactor with a length of 1m and a diameter of 0.02m, catalyst A is filled from the bottom of the tower to 1 / 3, with a filling mass of 60g, and 1 / 3 to 2 / 3 is filled with catalyst A and alkali at a mass ratio of 1:1 60g of the mixture of the mixed carrier, 2 / 3 to the top of the tower is filled with 60g of basic carrier, and 180g of catalyst and carrier are filled together. The raw material 2,2-dimethoxypropane is fed from the bottom of the tower through a flow meter at a flow rate of 90g / h. The temperature at the bottom of the tower is controlled at 280°C and the pressure is 0.2MPaG. The gas collected at the top of the tower is cooled and rectified , 59.81 g / h (reaction conversion rate 98.25%, selectivity 97.70%, yield 95.99%) product 2-methoxypropene was collected. The reaction was carried out continuously for 3000h, and no catalyst deactivation was found.

Embodiment 2

[0043] In a tower reactor with a length of 1m and a diameter of 0.02m, catalyst B is filled from the bottom of the tower to 1 / 3, the filling mass is 40g, and 1 / 3 to 2 / 3 is filled with catalyst B and The mixture of basic carriers is packed, the filling mass is 100g, the basic carrier is filled from 2 / 3 to the top of the tower, the filling mass is 40g, and the catalyst and carrier are filled with 180g. The raw material 2,2-dimethoxypropane is fed from the bottom of the tower at a flow rate of 70g / h through a flow meter. The temperature at the bottom of the tower is controlled at 270°C and the pressure is 0.3MPaG. The gas collected at the top of the tower is cooled and rectified , Collected 45.29g / h (reaction conversion rate 97.19%, selectivity 96.15%, yield 93.45%) product 2-methoxypropene. The reaction was carried out continuously for 3500h, and no catalyst deactivation was found.

Embodiment 3

[0045] In a tower reactor with a length of 1m and a diameter of 0.02m, catalyst A is filled from the bottom of the tower to 1 / 3, the filling mass is 60g, and 1 / 3 to 2 / 3 is filled with catalyst A and The mixture of basic carriers is packed, the filling mass is 60g, the basic carrier is filled from 2 / 3 to the top of the tower, the filling mass is 60g, and the catalyst and carrier are filled with 180g. The raw material 2,2-diethoxypropane is fed from the bottom of the tower at a flow rate of 90g / h through a flow meter. The temperature at the bottom of the tower is controlled at 300°C and the pressure is 0.25MPaG. The gas collected at the top of the tower is cooled and rectified , collected 53.74g / h (reaction conversion rate 99.46%, selectivity 92.15%, yield 91.65%) product 2-ethoxypropene. The reaction was carried out continuously for 3000h, and no catalyst deactivation was found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com