Organic compound and application thereof

A technology of organic compounds and chemical bonds, used in organic chemistry, electric solid devices, semiconductor devices, etc., can solve the problems of insufficient material mobility, high device voltage, and life to be improved, etc., to achieve high migration efficiency, extended service life, The effect of good thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

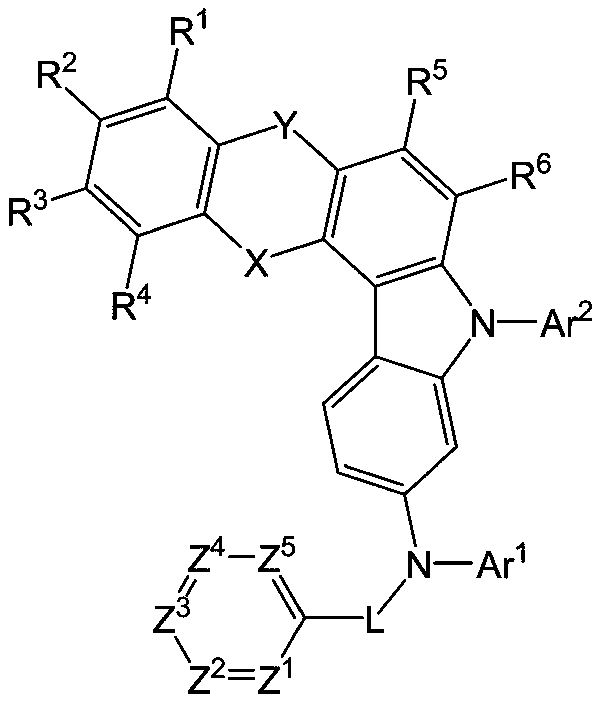

Method used

Image

Examples

Embodiment 1

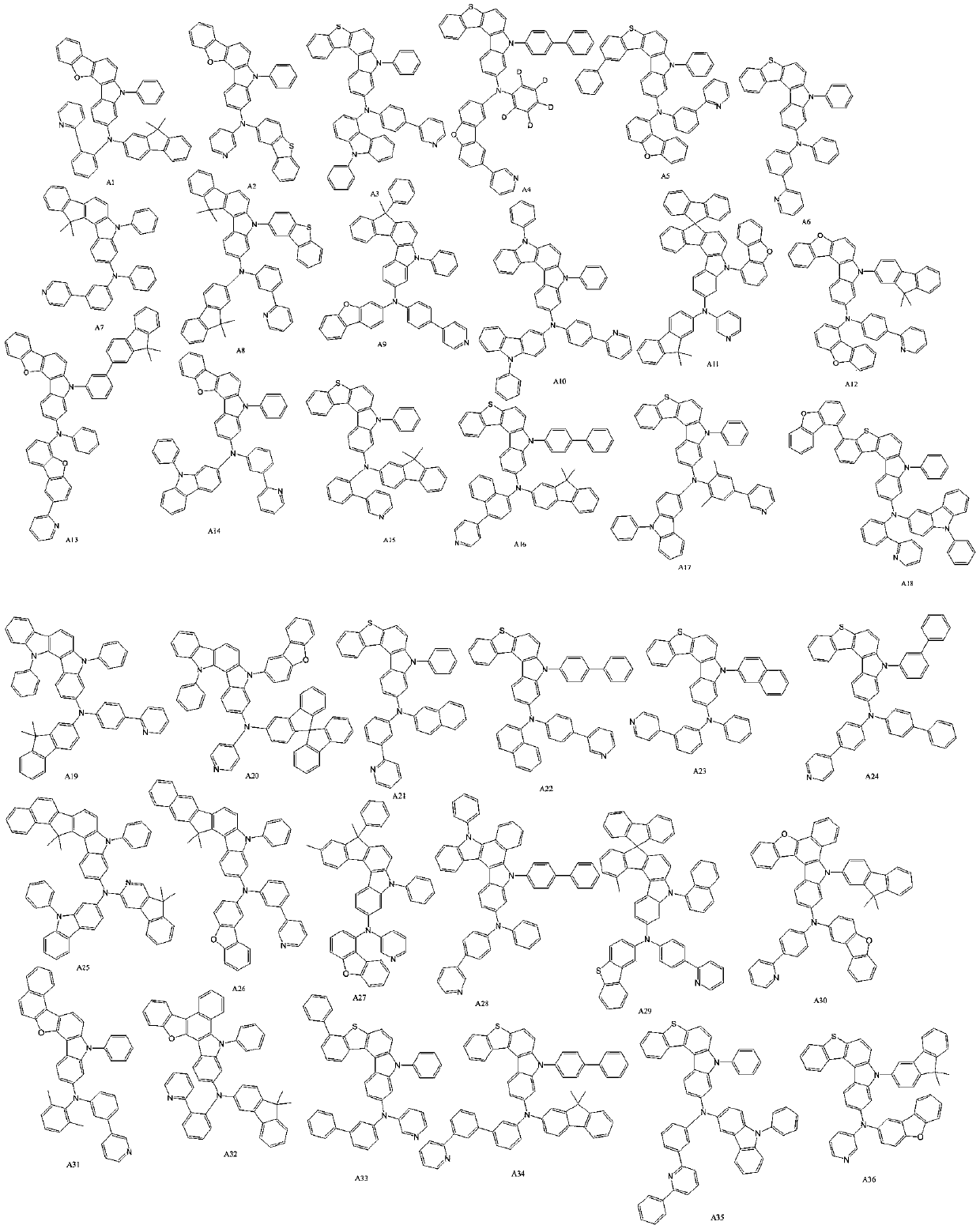

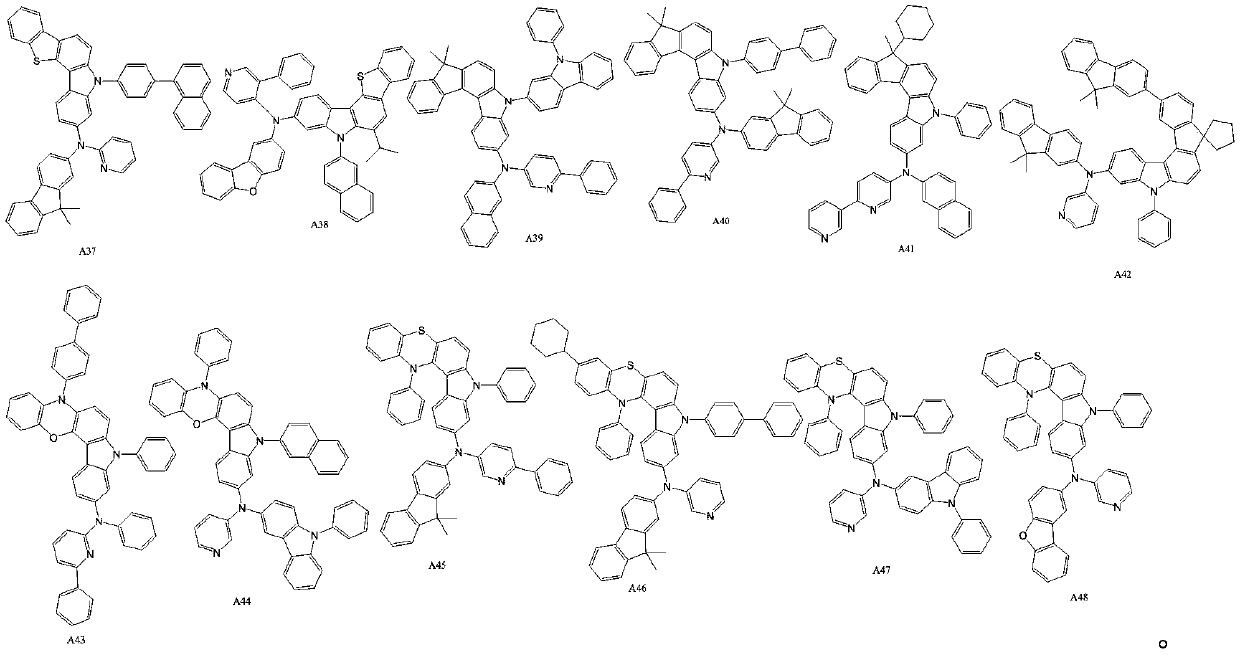

[0031] The synthesis of compound A1, the reaction equation is as follows:

[0032]

[0033] The synthesis method is as follows:

[0034] (1) In the reaction flask, add dibenzofuran-4-boronic acid (100mmol), 2-iodo-5-bromonitrobenzene (100mmol), 0.9g (0.785mmol, 0.5%) tetrakistriphenylphosphine palladium, Toluene 500mL, ethanol 200mL, water 200mL and potassium carbonate 40g (300mmol) were reacted at 100°C for 8h; after the reaction was completed, the reaction was stopped; cooled to room temperature, the organic phase was separated, concentrated, and silica gel column chromatography to obtain yellow powder M1;

[0035] (2) Add M1 (100mmol), triphenylphosphine (100mmol) and o-dichlorobenzene 1000mL into the reaction flask, heat to reflux, react for 12h, concentrate the reaction solution, and separate the intermediate M2 by column chromatography;

[0036] (3) In the reaction flask, add M2 (100mmol), iodobenzene (105mmol), CuI (1%), 1,10-phenanthroline (1%), xylene 800mL and po...

Embodiment 2

[0040] The synthesis of compound A6, reaction equation is as follows:

[0041]

[0042] The synthesis method is as follows:

[0043] (1) In the reaction flask, add dibenzothiophene-1-boronic acid (100mmol), 2-iodo-5-bromonitrobenzene (100mmol), 0.9g (0.785mmol, 0.5%) tetrakistriphenylphosphine palladium, Toluene 500mL, ethanol 200mL, water 200mL and potassium carbonate 40g (300mmol) were reacted at 100°C for 8h; after the reaction was completed, the reaction was stopped; cooled to room temperature, the organic phase was separated, concentrated, and silica gel column chromatography to obtain yellow powder M1;

[0044] (2) Add M1 (100mmol), triphenylphosphine (100mmol) and o-dichlorobenzene 1000mL into the reaction flask, heat to reflux, react for 12h, concentrate the reaction solution, and separate the intermediate M2 by column chromatography;

[0045] (3) In the reaction flask, add M2 (100mmol), iodobenzene (105mmol), CuI (1%), 1,10-phenanthroline (1%), xylene 800mL and po...

Embodiment 3

[0049] The synthesis of compound A10, the reaction equation is as follows:

[0050]

[0051] The synthesis method is as follows:

[0052] (1) In the reaction flask, add N-phenylcarbazole-4-boronic acid (100mmol), 2-iodo-5-bromonitrobenzene (100mmol), 0.9g (0.785mmol, 0.5%) tetrakistriphenylphosphine Palladium, toluene 500mL, ethanol 200mL, water 200mL and potassium carbonate 40g (300mmol), react at 100°C for 8h; after the reaction is completed, stop the reaction; cool to room temperature, separate the organic phase, concentrate, and perform silica gel column chromatography to obtain yellow powder M1;

[0053] (2) Add M1 (100mmol), triphenylphosphine (100mmol) and o-dichlorobenzene 1000mL into the reaction flask, heat to reflux, react for 12h, concentrate the reaction solution, and separate the intermediate M2 by column chromatography;

[0054] (3) In the reaction flask, add M2 (100mmol), iodobenzene (105mmol), CuI (1%), 1,10-phenanthroline (1%), xylene 800mL and potassium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com