High-performance durable shield segment lining structure for sea area corrosive environment

A technology for corrosive environment and shield segment, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of corroded segment connecting bolts and concrete lining, etc., and achieves good waterproof effect, safe and reliable structure, and construction risk. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

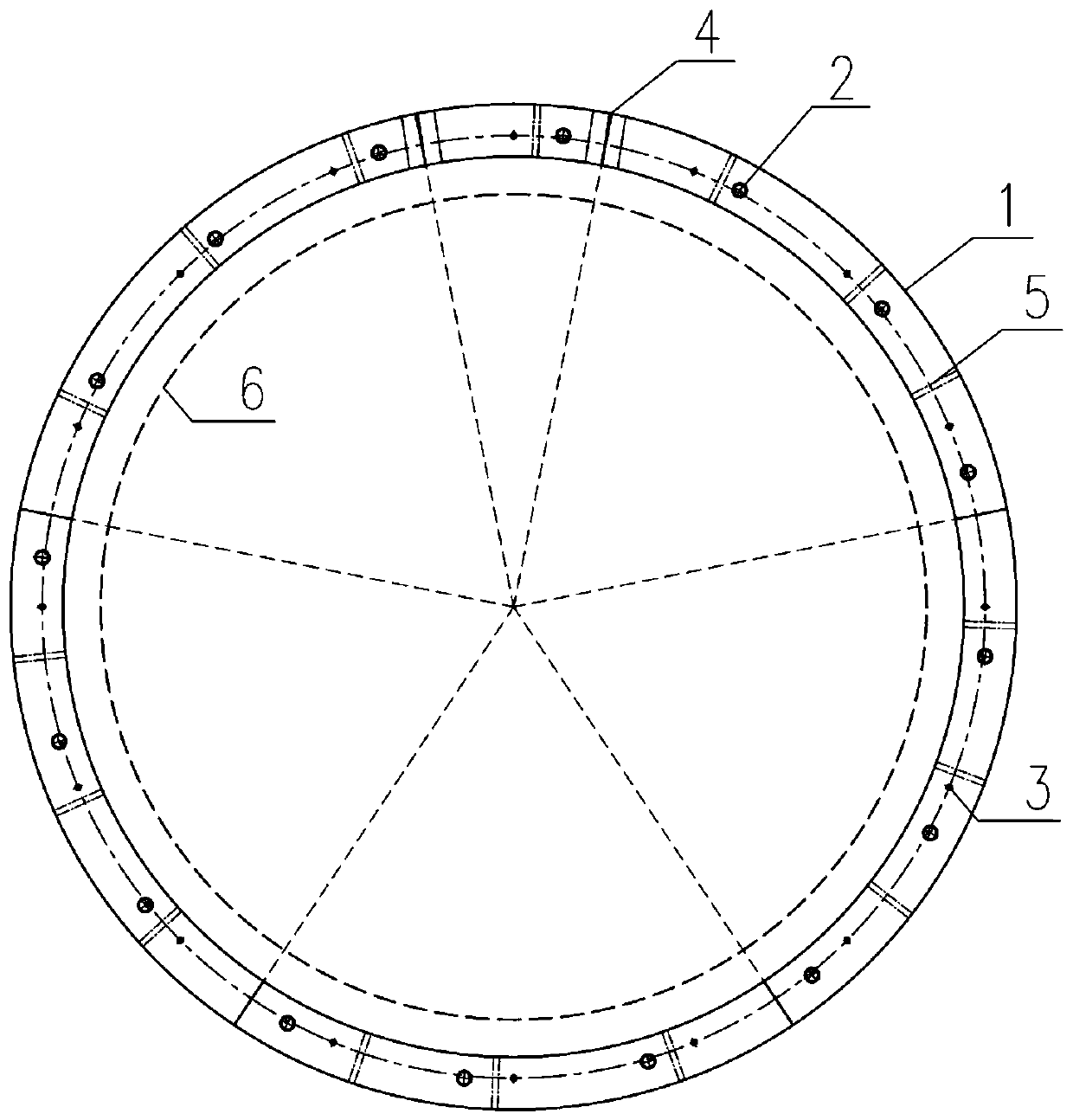

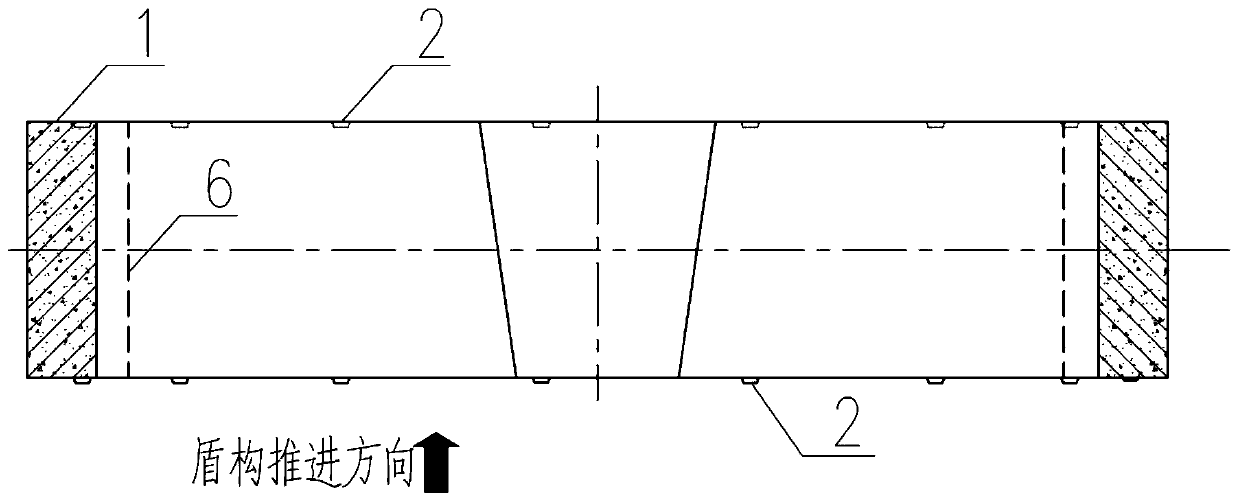

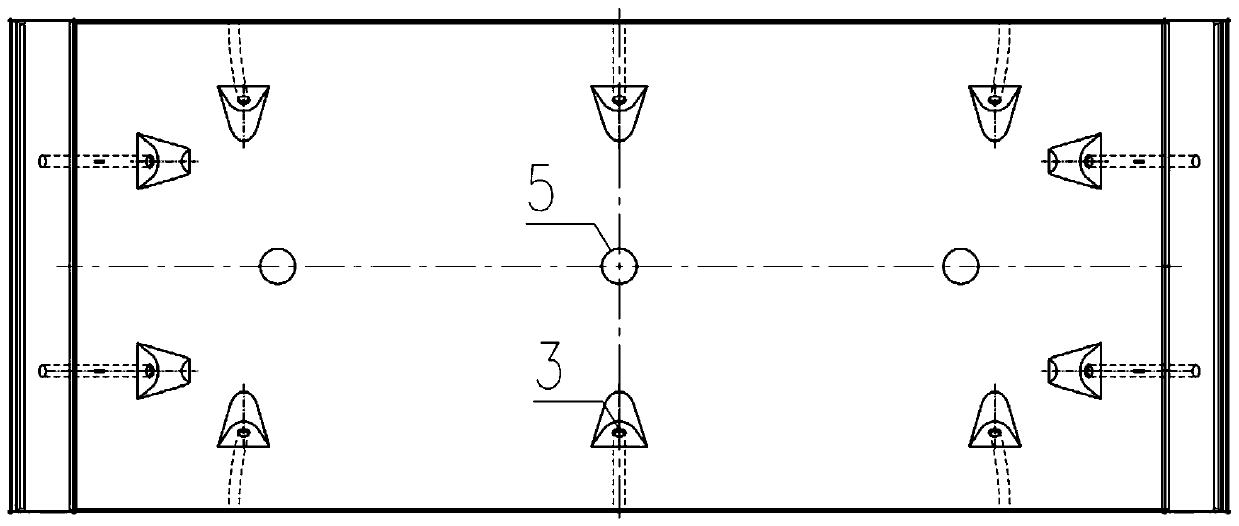

[0025] The embodiment of the present invention discloses a high-performance and durable shield segment lining structure in sea area corrosion environment, as shown in the figure, including high-performance concrete segment 1, tenon-shaped connection 2, high-performance corrosion-resistant bolt 3, multiple waterproofing System 4, reinforced grouting system 5 and reserved reinforcement space 6, multiple high-performance concrete segments 1 are connected and fixed by high-performance corrosion-resistant bolts 3, the ring direction is assembled by tenon-shaped connections 2, and each joint is waterproofed by multiple The system 4 is sealed and waterproof, and a reinforced grouting system 5 is set between the back of the high-performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Minimum tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com