Super-sensitive gas sensor based on graphene D-shaped optical fiber

A gas sensor and graphene technology, which is applied in the field of sensing, can solve the problems of improving the sensitivity of the D-shaped optical fiber sensor, limiting the sensitivity of the sensor, etc., and achieve the effect of improving the sensing response capability, simple structure and small device volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and examples.

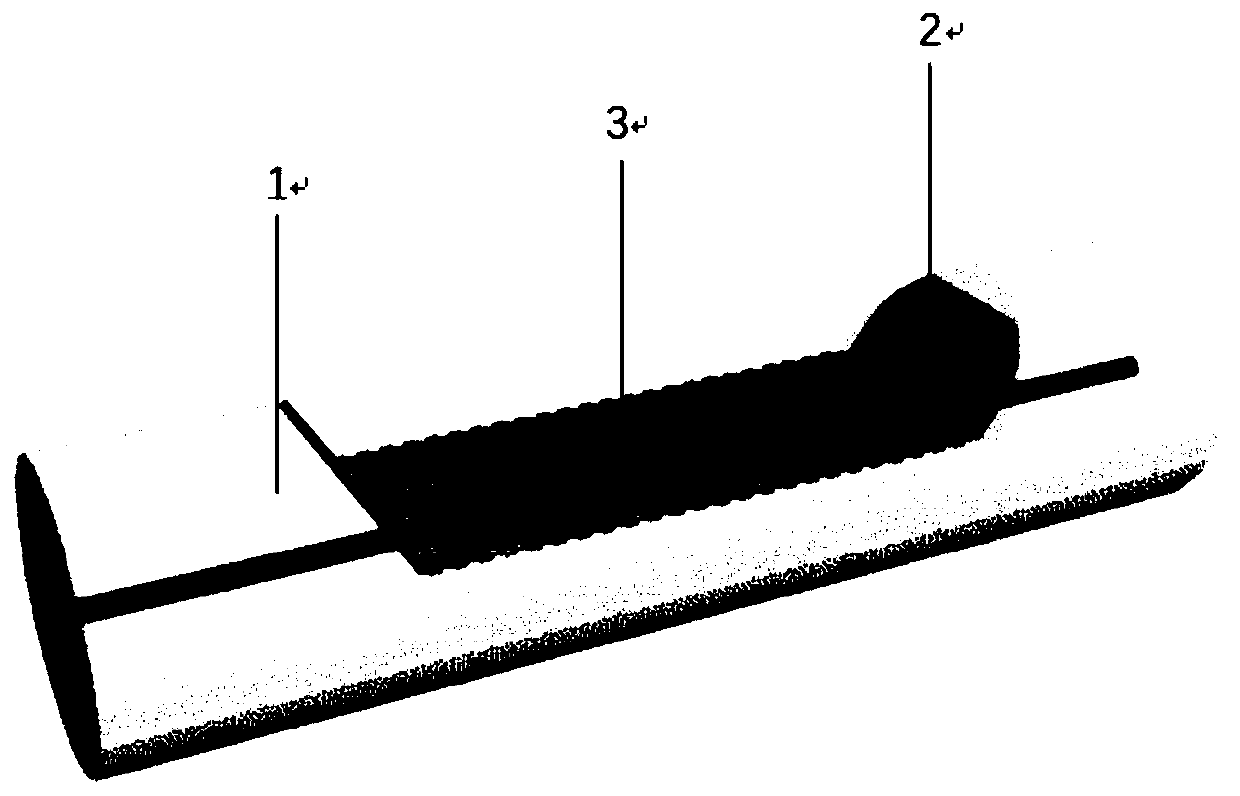

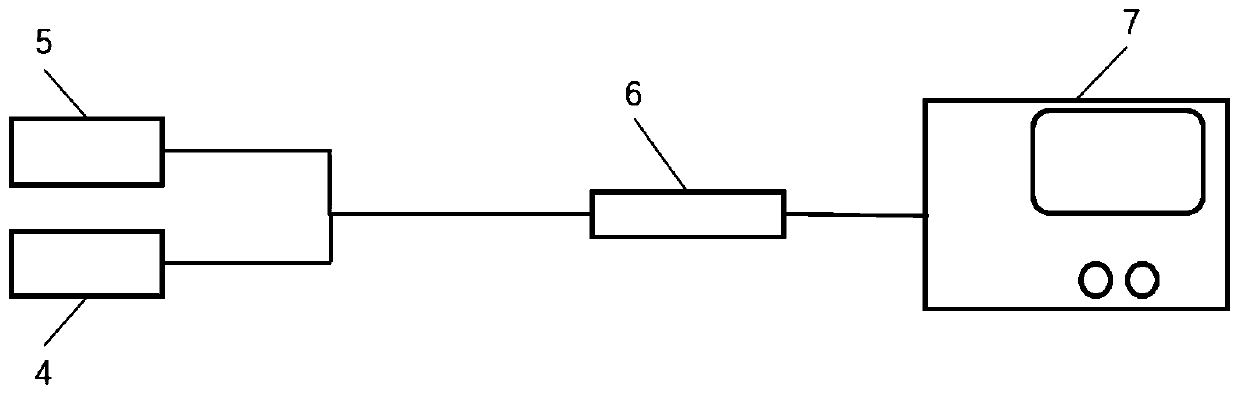

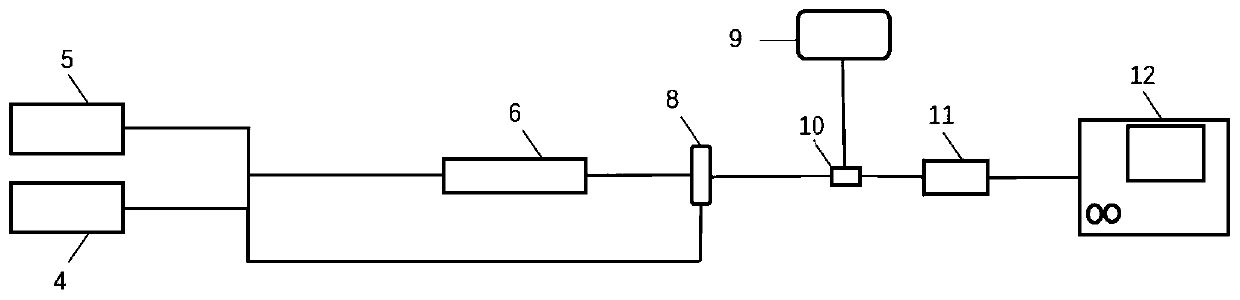

[0023] An ultrasensitive gas sensor based on a graphene D-shaped optical fiber, comprising a D-shaped optical fiber (1), a graphene film (3), and a gold-graphene-gold heterojunction structure. The D-shaped optical fiber (1) is formed by polishing a single-mode optical fiber with a core diameter of 8 microns. The graphene film (3) is attached to the polished surface of the D-shaped optical fiber, and the gold film (2) with a thickness of 50 nm is sprayed on the D-shaped optical fiber (1) by mask spraying method to form a complete gas sensing structure .

[0024] combine figure 1 , figure 2 As shown in the figure, select a part with a length of 5 cm and a core diameter of 8 microns on a single-mode optical fiber with a length of 1 meter to remove the coating layer, and polish the center of the fiber with the coating layer removed by side polishing . A D-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com