Visual window for pipeline of supercritical water-cooled reactor and sealing method thereof

A water-cooled reactor and supercritical technology, which is applied in nuclear reactor monitoring, reactors, cooling devices, etc., can solve the problems of unstable manufacturing process structure, non-visualization of experimental devices, and inability to carry out detailed research, so as to meet experimental needs and engineering applications , Eliminate uneven crystallization and prevent nuclear radiation leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

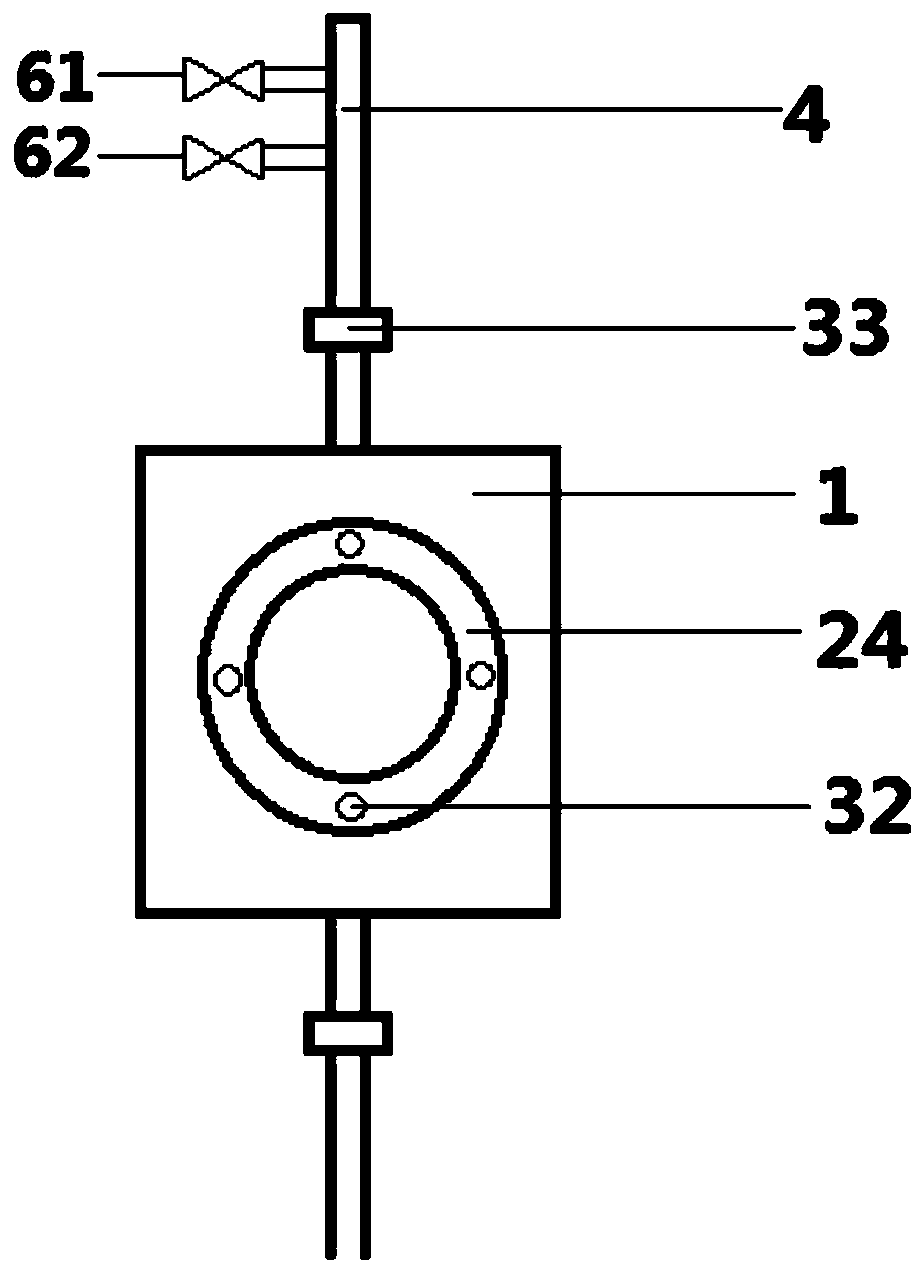

[0130] Embodiment 1 A kind of visual window of supercritical cold water reactor piping, such as figure 1 shown.

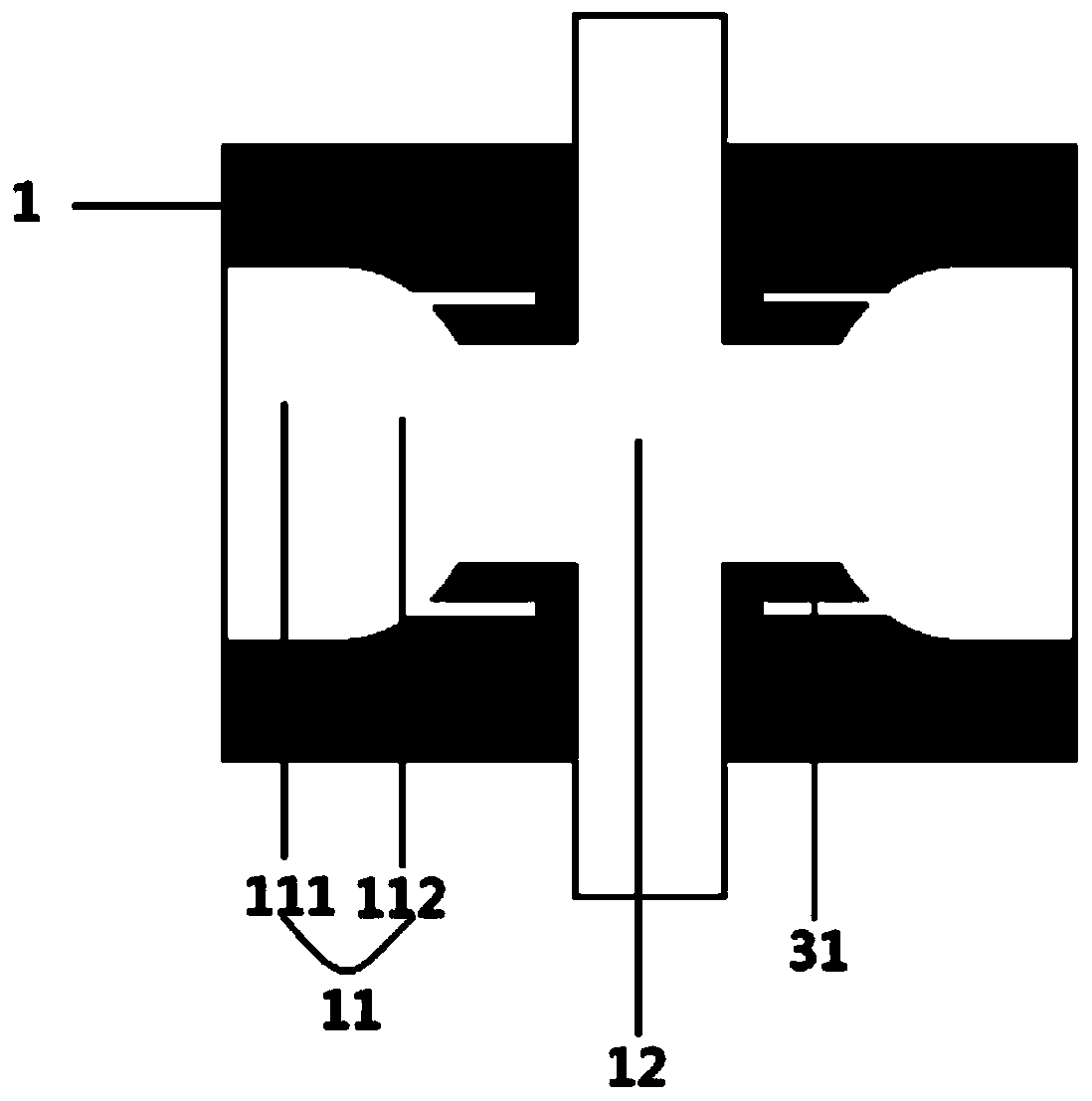

[0131] Among them, the base of the visible window is cast from a lead-copper alloy with a mass fraction of 33% lead. There is a cross channel in the base. The installation hole includes a cylindrical section and a curved surface section. The curved surface section communicates with the channels on the left and right sides of the cross channel. , with 4 threaded holes at the bottom.

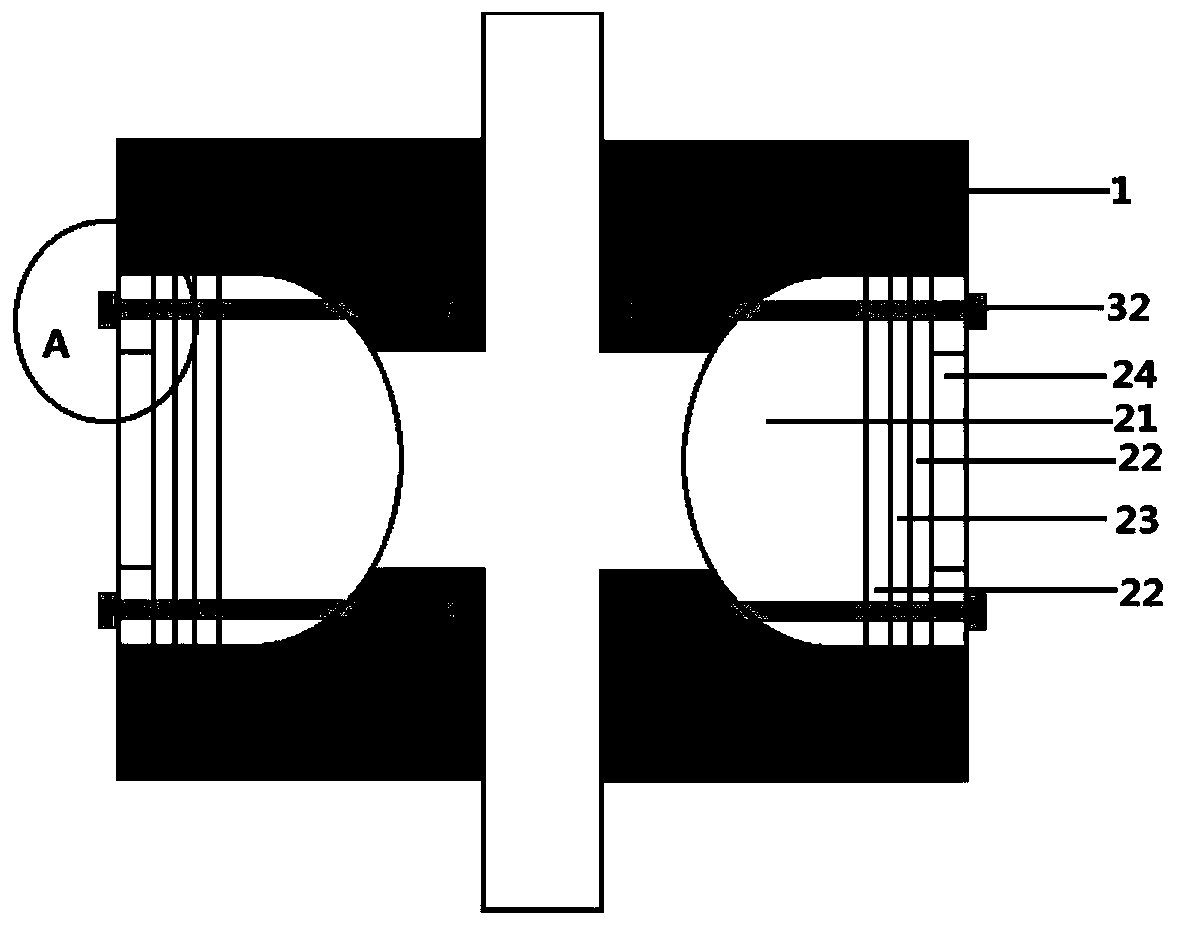

[0132] The window consists of a 10mm thick lead platen, a 5mm thick sealing gasket, a 10mm sapphire lens, a 5mm thick sealing gasket and a 20mm thick plano-convex lens lens.

[0133] The window and the base are connected by 4 lead bolts, and the base and the supercritical water-cooled reactor pipeline are connected by 2 lead nuts.

[0134] When using:

[0135] 1) In the installation hole, from the inside to the outside, install a plano-convex lens lens with a thickness of 20mm, a se...

experiment example 1

[0140] Experimental Example 1 Sealing coating resistance to alternating cold and heat performance experiment

[0141] After the window in embodiment 1 and the base are connected together by lead bolts, adopt the cold spray technology in embodiment 1 to be sprayed with the graphene anti-radiation coating that one deck thickness is 3mm at the junction of window and base, obtain Test sample 1.

[0142] Put the test sample 1 in the muffle furnace, raise the temperature to 500°C, keep it warm for 10 hours, take it out, and soak it in cold water for 1 hour, which is 1 cycle. Repeat 5 cycles to observe the change of the sealing coating.

[0143] After 5 cycles of alternating heat and cold experiments, the sealing coating on test sample 1 did not appear to fall off or crack, indicating that the sealing coating has good resistance to alternating cold and heat, and the prepared window can withstand nuclear reaction cold water reactor pipes. pressure and temperature in.

experiment example 2

[0144] Experimental Example 2 Sealing Test of Visible Window

[0145] Install the viewing window on the critical water-cooled reactor pipeline, open the valve on the supercritical water-cooled reactor pipeline, and use the SPD-100 personal dosimeter to test the tightness of the visual window when the fluid flows through the visual window.

[0146] It can be seen from the test results that the radiation dose near the visible window does not exceed 2.5μSv per day. It can be seen that the visible window in Example 1 not only has good sealing performance, but also can prevent the leakage of radioactive substances. Through the visual window, it can be used to observe the flow of supercritical high-temperature and high-pressure water in the pipeline, conduct hydraulic analysis and study the turbulent deposition law of fine particles in the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com