Drilling and punching integrated device

An integrated, drilling and punching technology, applied in leather punching/punching/cutting, textile and paper making, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problem that the punching depth cannot be grasped and punching is easy to occur Problems such as burrs and complex drilling and punching structures can reduce the failure rate and the difficulty of subsequent maintenance, reduce the installation space, and save the installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

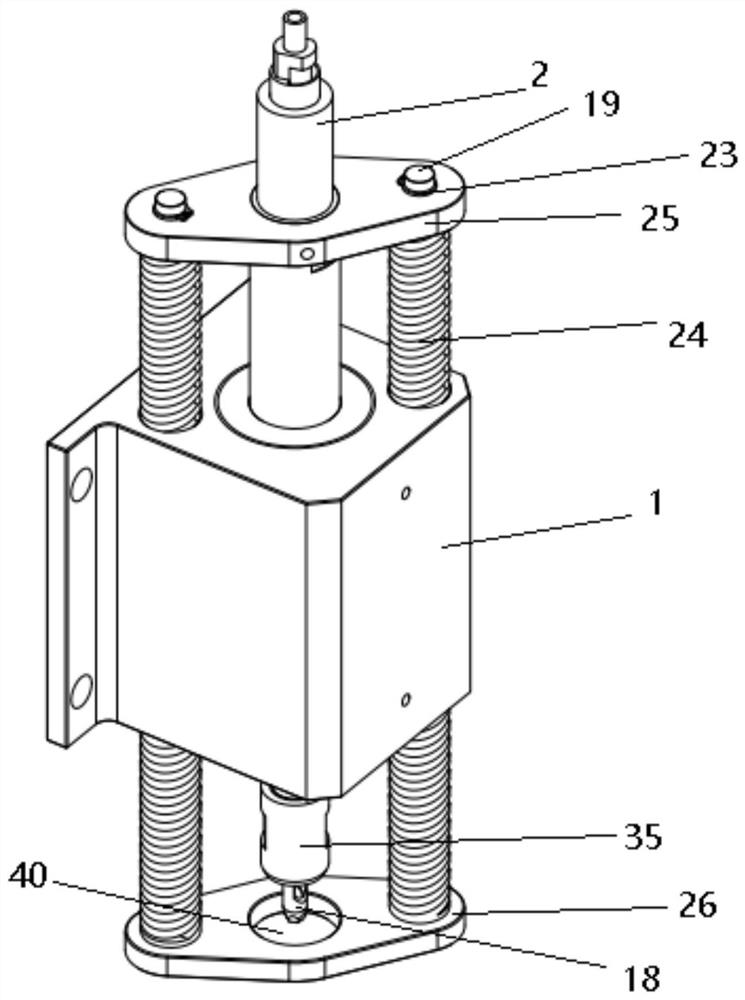

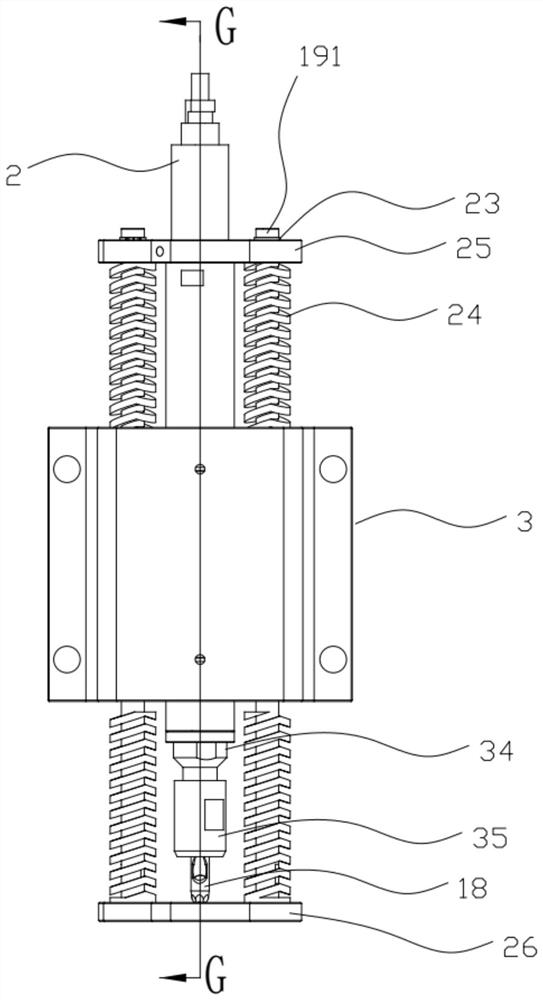

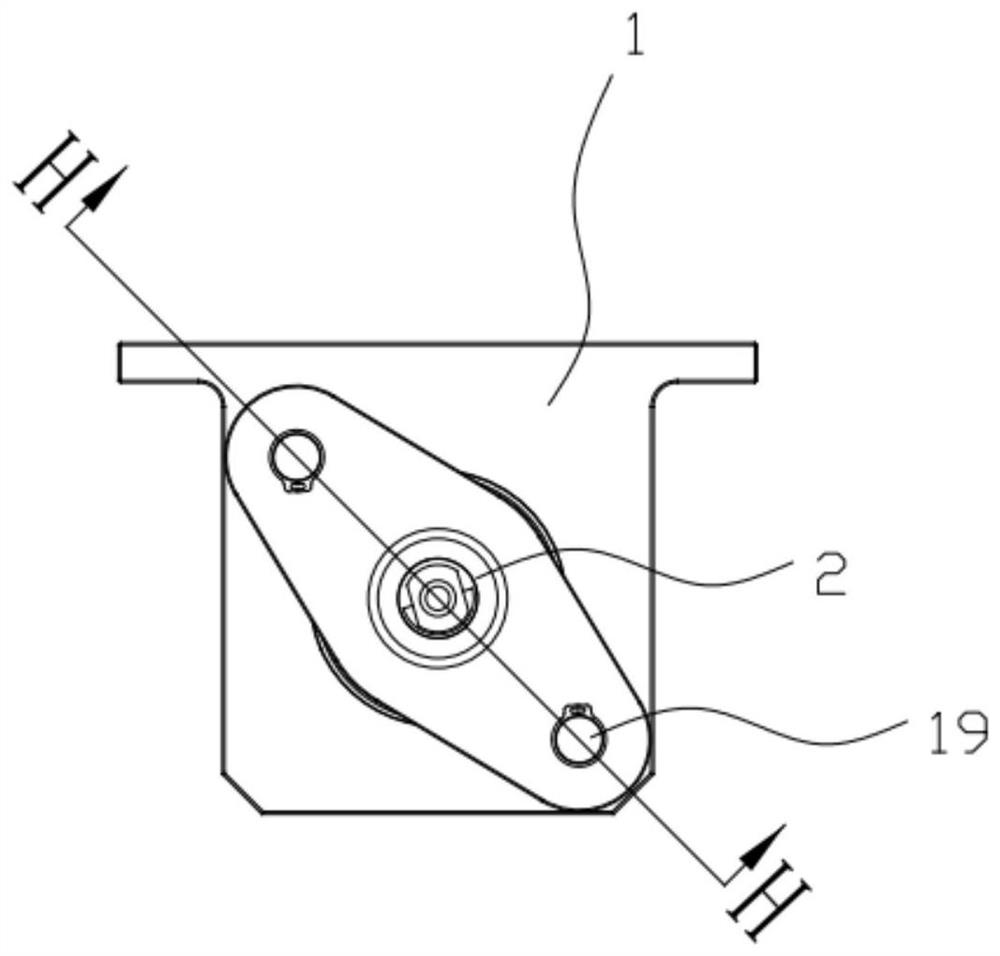

[0029] See Figure 1-Figure 5 , figure 1 Shown is a three-dimensional schematic view of the drilling and punching integrated device according to the present invention; figure 2 shown as figure 1 The front view of the drilling and punching integrated device in ; image 3 shown as figure 1 The top view of the drilling and punching integrated device in ; Figure 4 shown along figure 2 The cross-sectional schematic diagram of the drilling and punching integrated device along the GG line in ; Figure 5 shown along image 3 The cross-sectional schematic diagram of the drilling and punching integrated device along the HH line in . The present invention provides a drilling and punching integrated device, which can be applied to leather cloth, but the present invention is not limited thereto, and punches can be selected according to actual needs to meet actual usage conditions. Wherein, in the present invention, the drilling and punching integrated device includes: a radial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com