Brewing method of sparkling semi-sweet yellow rice wine

A technology of sweet rice wine and rice wine, applied in the preparation of alcoholic beverages, etc., can solve the problems of affecting the quality and flavor of finished products, reducing the alcohol content of raw wine, and short duration, so as to improve the body's immunity and disease resistance, promote proliferation, Slow down the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weighing materials: Weigh aged semi-dry rice wine (aged rice wine), sweet rice wine (Xiangxue wine), isomaltooligosaccharide, chitosan oligosaccharide, tea saponin, highly active dry distiller's mother and water;

[0029] The weight ratio of aged semi-dry rice wine (aged rice wine), sweet rice wine (Xiangxue wine), isomaltooligosaccharide, chitooligosaccharide, tea saponin, highly active dry distiller's mother and water is: aged semi-dry rice wine (Old rice wine) 39.5, sweet rice wine 8.5, isomalto-oligosaccharide 2.0, chitosan oligosaccharide 1.0, tea saponin 0.5, high activity dry distiller's mother 0.003 and water 40.0.

[0030] (2) Feeding: Put aged semi-dry rice wine (aged rice wine), sweet rice wine (Xiangxue wine), isomaltooligosaccharide, chitosan oligosaccharide, tea saponin, highly active dry distiller's mother and water into a pressure-resistant container bottle;

[0031] (3) Fermentation: put the above-mentioned materials into the bottle, cover and seal...

Embodiment 2-6

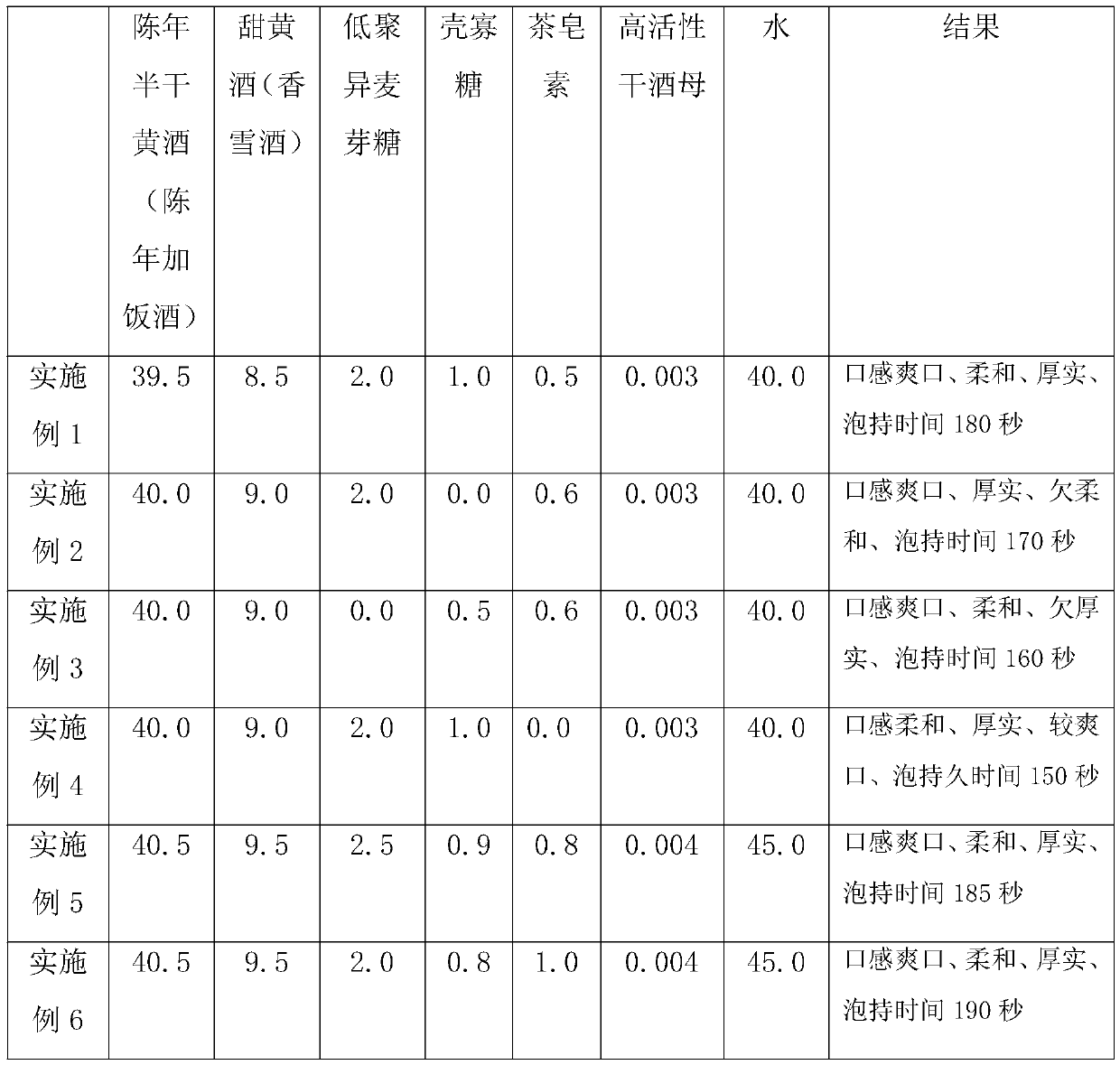

[0035] Embodiment 2-6 (for studying the influence of each material ratio on yellow rice wine)

[0036] Embodiment 2-6 others are all identical with embodiment 1, except that the proportioning of each material in step (1) is different, specifically following table 1:

[0037] Table 1

[0038]

Embodiment 7-10

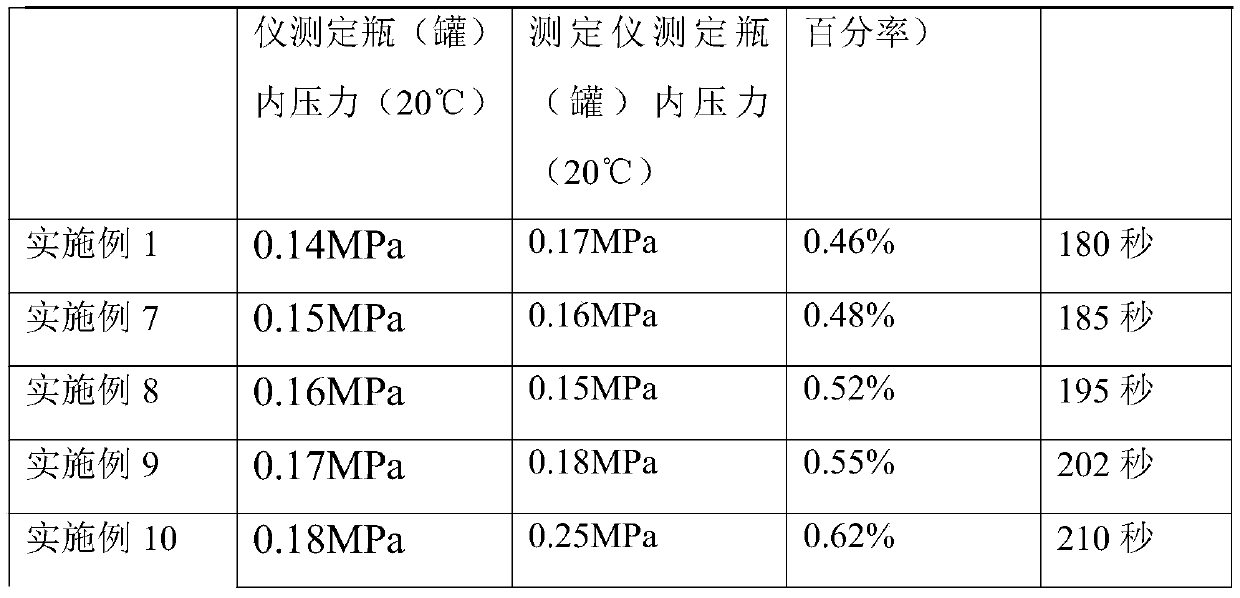

[0039] Embodiment 7-10 (for studying the impact of different pressures in the bottle on the content and persistence of carbon dioxide measured by the carbon dioxide manometer after sterilization)

[0040]

[0041]

[0042] At the end of fermentation, the carbon dioxide pressure tester measures the pressure (20°C) inside the bottle (tank) [and after sterilization (finished product) the carbon dioxide pressure tester measures the pressure (20°C) inside the bottle (tank) are two concepts. During fermentation, the pressure inside the bottle will increase] The fermentation process should not exceed 0.20MPa, otherwise, the temperature will rise to 90°C during sterilization, which will exceed the pressure resistance of the bottle, and the bottle will burst and cannot be produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com