Method for testing the high-resolution three-dimensional refractive index of microstructure optical fiber

A micro-structured optical fiber and high-resolution technology, which is applied in the measurement of phase influence characteristics, etc., and can solve problems such as complex and complicated devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

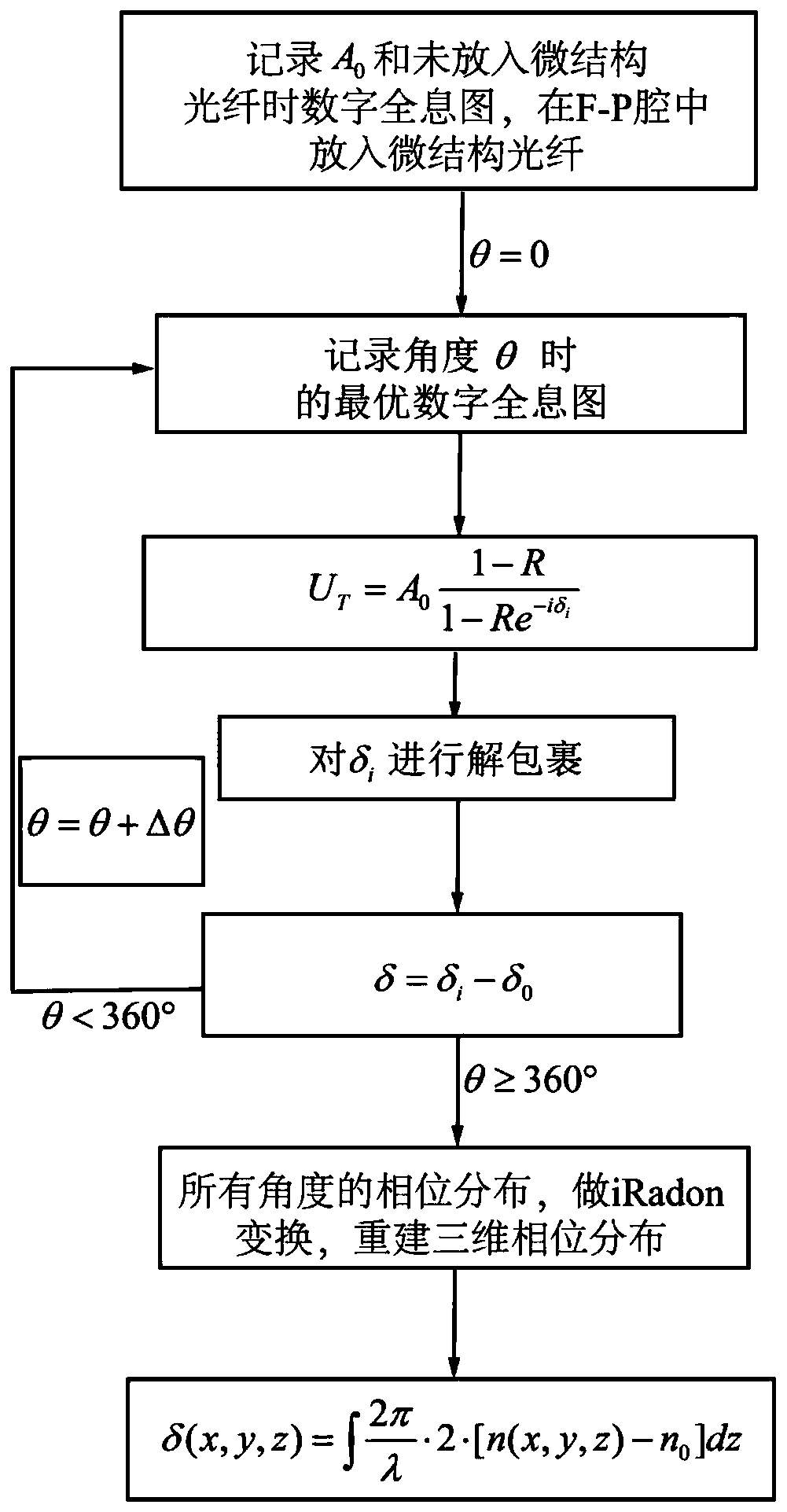

Method used

Image

Examples

Embodiment 1

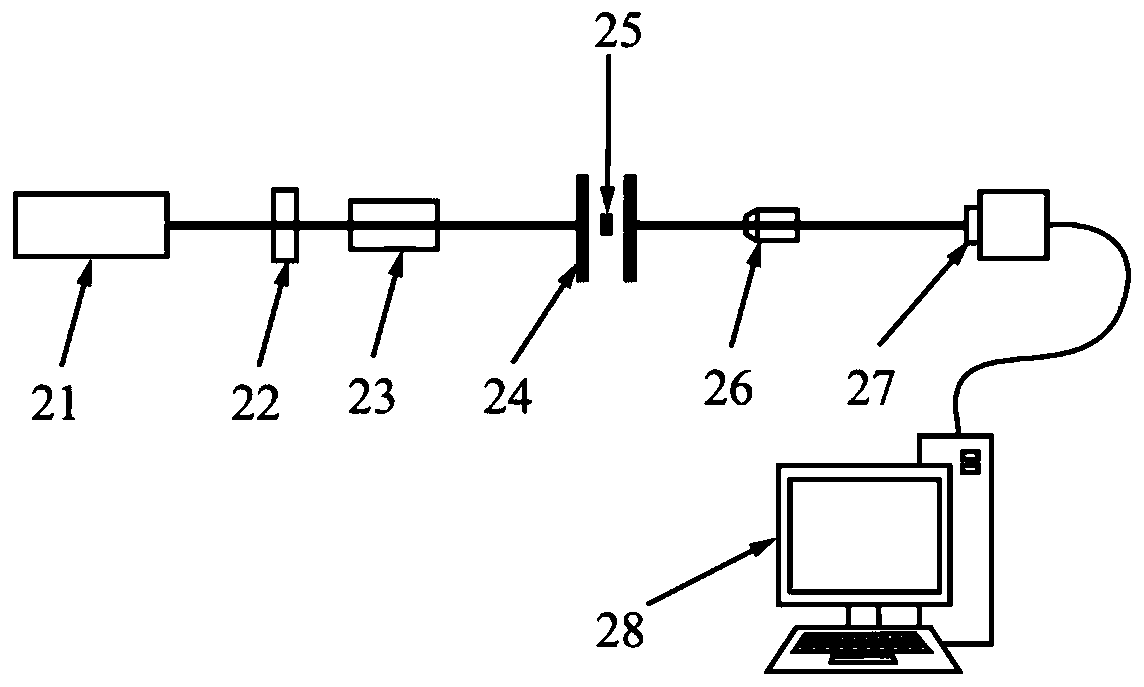

[0064] Figure 2b An embodiment of digital holographic recording optical path based on F-P cavity is given. The optical path includes a light source 21 , an attenuator 22 , a beam expander 23 , an F-P etalon 24 , a microstructured optical fiber 25 , a microscope objective lens 26 , a CCD 27 and a computer 28 . The light beam starts from the light source 21, passes through the attenuator 22, and the energy of the light beam weakens, the light beam passes through the beam expander 23, and the diameter of the light beam expands, and when the light beam passes through the F-P etalon 24 with the microstructured optical fiber 25, it is repeatedly reflected at the F-P etalon 24, After passing through the microstructured optical fiber 25 multiple times, each beam of transmitted light passing through the F-P etalon 24 passes through the microscope objective lens 26, and then interferes and superimposes on the CCD 27. The digital hologram of the interference is recorded by the CCD 27 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com